Method for breaking hard seeds of astragalus mongholicus

A technology of Astragalus seeds and Astragalus mongolica, which is applied in the directions of seed and rhizome treatment, application, agriculture, etc., can solve problems such as research on seed emergence morphology, and achieve the effect of improving permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for breaking the hardness of Astragalus mongolica seeds, the method is:

[0026] S1 selects astragalus seeds of uniform size; the diameter of the seeds is 2.5cm to 2.9cm;

[0027] S2 Use a laser engraving machine to laser treat Astragalus seeds, the laser power is 1200mW, and the laser treatment depth is 0.4mm;

[0028] The laser volume of the laser engraving machine is 153×153×145mm, and the four process parameters are as follows:

[0029] 1) Selection of engraving mode: the engraving mode includes "black and white" or "discrete"; the "discrete" mode will output the picture as a discrete image, and engrave in the form of a fine grid; the "black and white" mode maintains the continuity of the picture for engraving;

[0030] 2) Contrast: the range is 0~253, which measures the ratio of black and white of the image, which is related to the color difference of the imported image;

[0031] 3) Engraving power: the laser head power is 3000mW, and the range is 40%; ...

Embodiment 2

[0036] Connect the device, import the design drawing into the software, and set the software parameters: choose "black and white" for laser engraving mode, and the default option for contrast. Set laser engraving power 20%, 40%, 60%, 80%, 100%, corresponding to actual power 600mW, 1200mW, 1800mW, 2400mW, 3000mW; select laser engraving depth 20%, 40%, 60%, 80%, 100 %, corresponding to the actual depth of 0.2mm, 0.4mm, 0.6mm, 0.8mm, 1.0mm. Design and set up 25 groups of treatments, with Astragalus seeds without laser treatment as the control, a total of 26 groups of different treatment methods were set up, and the experimental factor levels are as follows.

[0037] Table 1 Different processing laser engraving machine parameters

[0038]

[0039]

[0040] Note: A0B0 is the control without laser treatment.

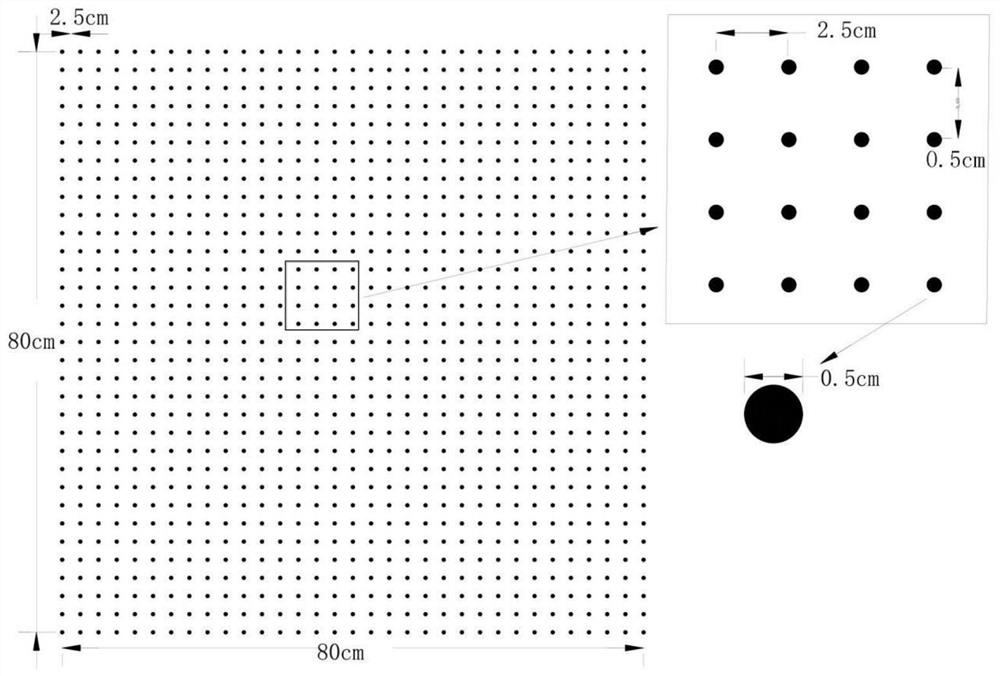

[0041] Each group was treated with 10g of astragalus seeds. Place the astragalus seeds in a single layer evenly on a 80×80cm wooden plate, select the “frame positioni...

Embodiment 3

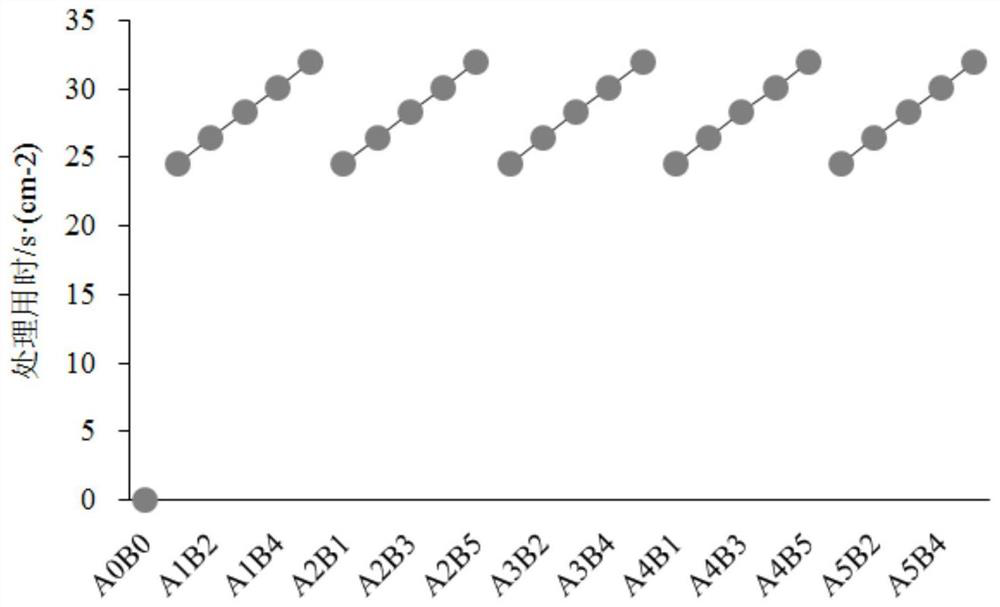

[0047] The relationship between different laser treatment intensity and treatment time

[0048] Such as figure 2 As shown, the laser processing time is only related to the laser drilling depth, showing a linear positive correlation. When the treatment depth is 0.2mm, the unit area (cm 2 ) drilling takes 24.52s, and when the processing depth is 1mm, the processing time is 31.93s. The following formula can be obtained, and the processing time (s) can be calculated according to the processing depth (mm). It can be seen that the smaller the laser depth selected when processing seeds, the shorter the processing time.

[0049] T(s / cm 2 )=24.52+(X-0.2)*1.85

[0050] Note: T is the processing time, X is the processing depth (mm)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com