Zeolite protective mask and preparation method thereof

A mask and zeolite technology, applied in the field of masks, can solve the problems of poor cleanliness, peculiar smell and moisture, low filtering efficiency and antibacterial rate of masks, etc., and achieve the effect of good filtering performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

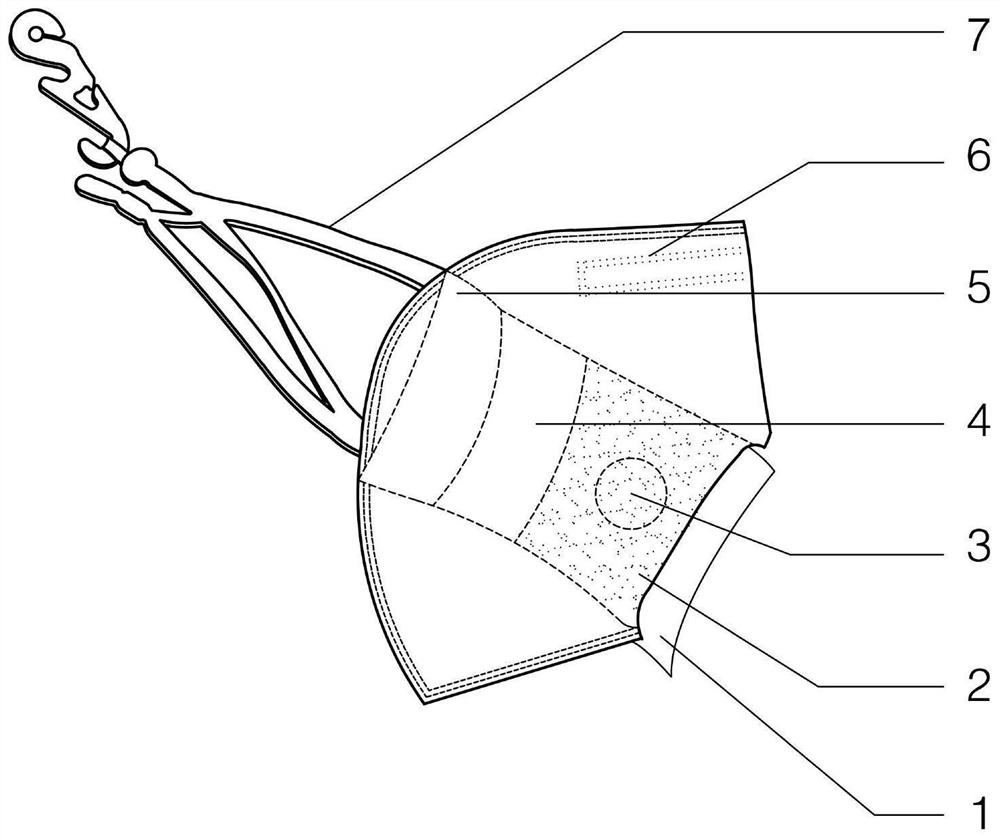

[0017] A zeolite protective mask, comprising a mask body, a nose bridge strip 6 is arranged at the inner edge of the side where the mask body contacts the bridge of the nose, adjustable ear straps 7 are also arranged on both sides of the mask body, the mask body includes Water-resistant and skin-friendly polypropylene non-woven fabric 1, melt-blown non-woven fabric 2, hot-air cotton non-woven fabric 4 and water-resistant polypropylene non-woven fabric 5, melt-blown non-woven fabric 2 and hot-air cotton non-woven fabric The cloth 4 is compounded with zeolite particles 3 through the melt-blown process, water-resistant and skin-friendly polypropylene non-woven fabric 1, melt-blown non-woven fabric 2, hot-air cotton non-woven fabric 4 and water-resistant polypropylene non-woven fabric 5 The mask body is formed by connecting by lapping and sewing process. Among them, the zeolite particles 3 are located between the melt-blown non-woven fabric 2 and the hot-air cotton non-woven fabri...

Embodiment 2

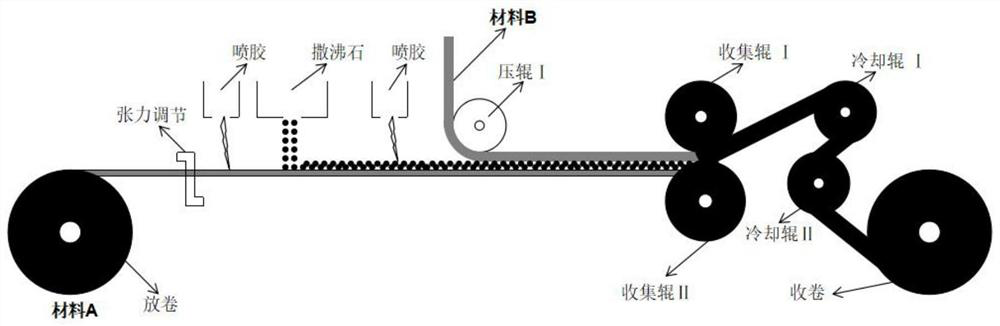

[0022] In the preparation method of the above zeolite protective mask, the zeolite sprayed at high pressure is wrapped between the melt-blown non-woven fabric and the hot-air cotton non-woven fabric after rolling. Both the melt-blown non-woven fabric and the hot-air cotton are melted by raw material particles to form a melt The post-spraying structure obtains the pre-laminated barrier zeolite core layer, and then connects the water-resistant and skin-friendly polypropylene non-woven fabric, the barrier zeolite core layer and the water-resistant non-woven fabric through the lapping and sewing process to obtain the mask body . Wherein the order number of zeolite in the present embodiment is 20~30 orders, consumption is 10g / m 2 The zeolite protective mask prepared by the above process conditions has high adsorption and good protection, but it is easy to block during the use of the equipment, and it needs to be frequently blocked.

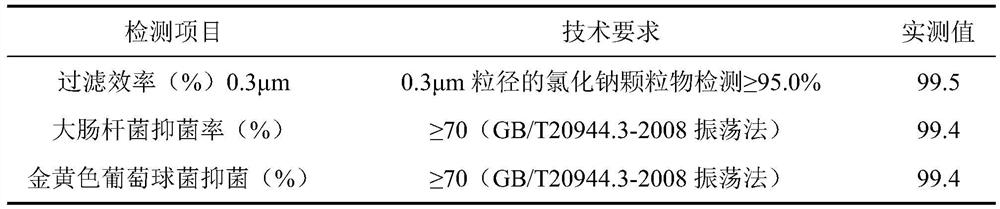

[0023] The antibacterial performance test resul...

Embodiment 3

[0026] In the preparation method of the above zeolite protective mask, the zeolite sprayed at high pressure is wrapped between the melt-blown non-woven fabric and the hot-air cotton non-woven fabric after rolling. Both the melt-blown non-woven fabric and the hot-air cotton are melted by raw material particles to form a melt The post-spraying structure obtains the pre-laminated barrier zeolite core layer, and then connects the water-resistant and skin-friendly polypropylene non-woven fabric, the barrier zeolite core layer and the water-resistant non-woven fabric through the lapping and sewing process to obtain the mask body . In this embodiment, the mesh number of zeolite is 40-60 mesh, and the dosage is 50g / m 2 ; Adopt the zeolite protective mask prepared by the above-mentioned process conditions, the air permeability and protection all meet the national standard.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com