Dessert processing device

A processing device and dessert technology, applied in dairy products, cheese substitutes, household utensils, etc., can solve the problems of non-delicacy, discounted dessert taste, and inability to disperse particles, so as to improve the degree of fineness, good stirring effect, and improve cutting The effect of the shattering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

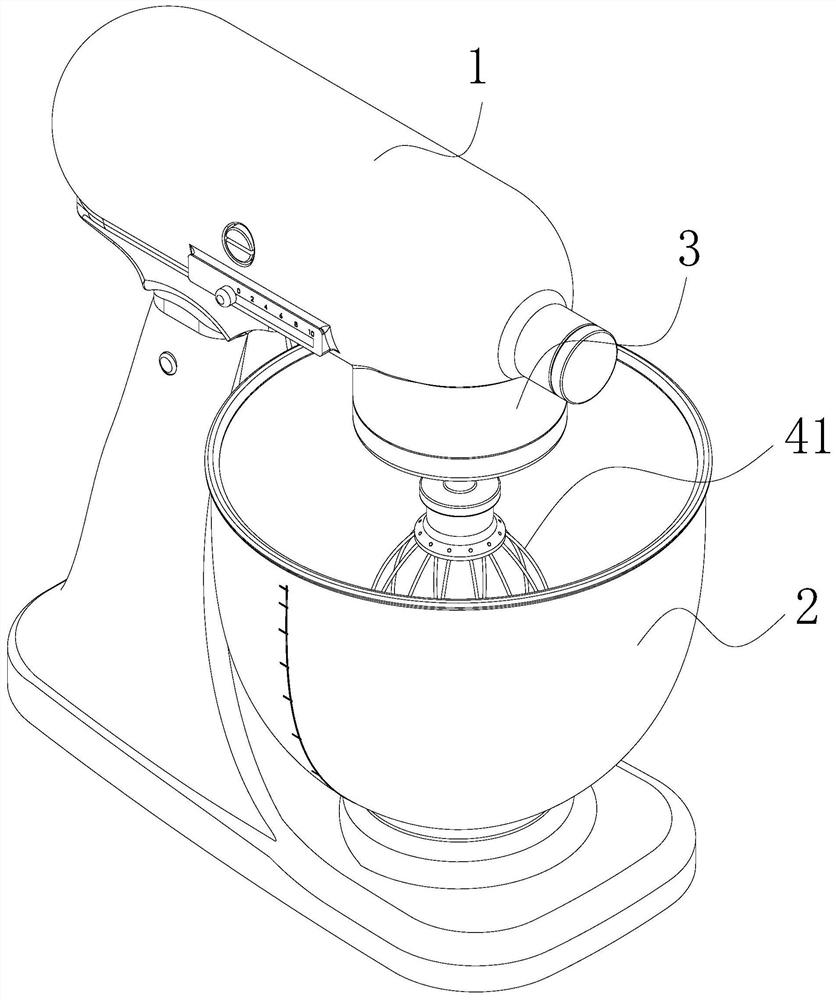

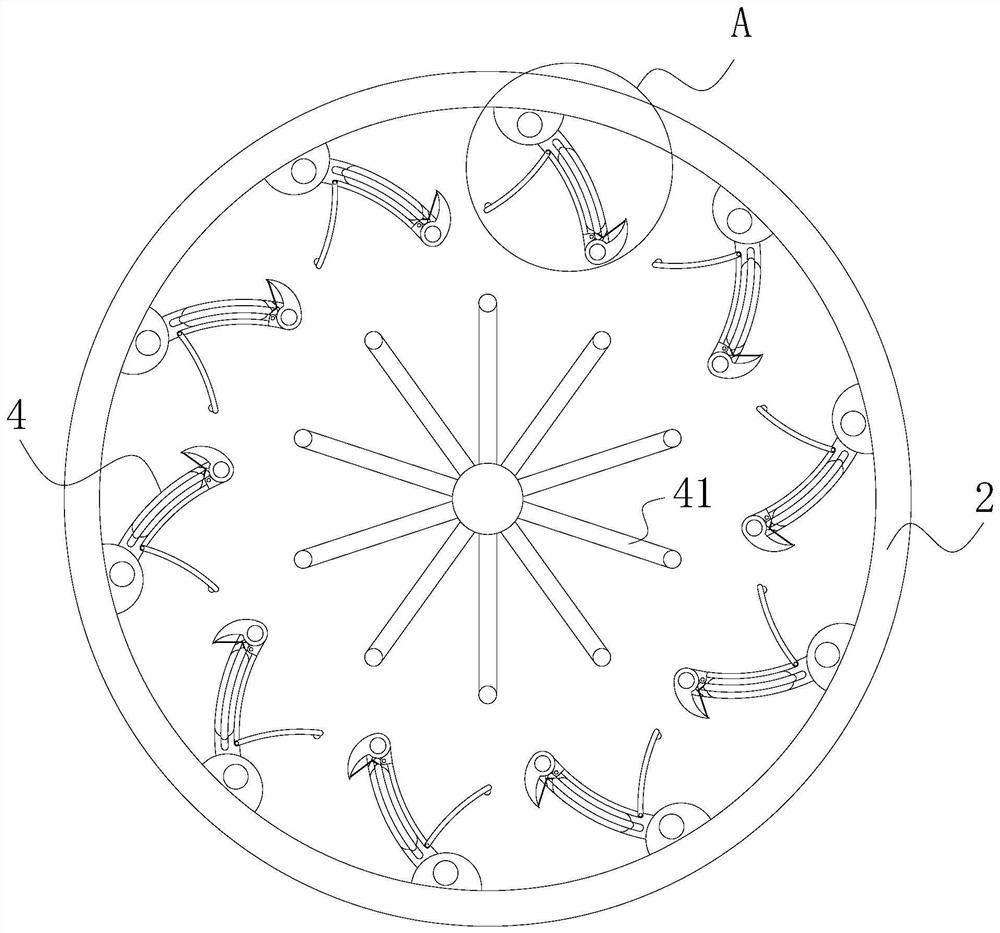

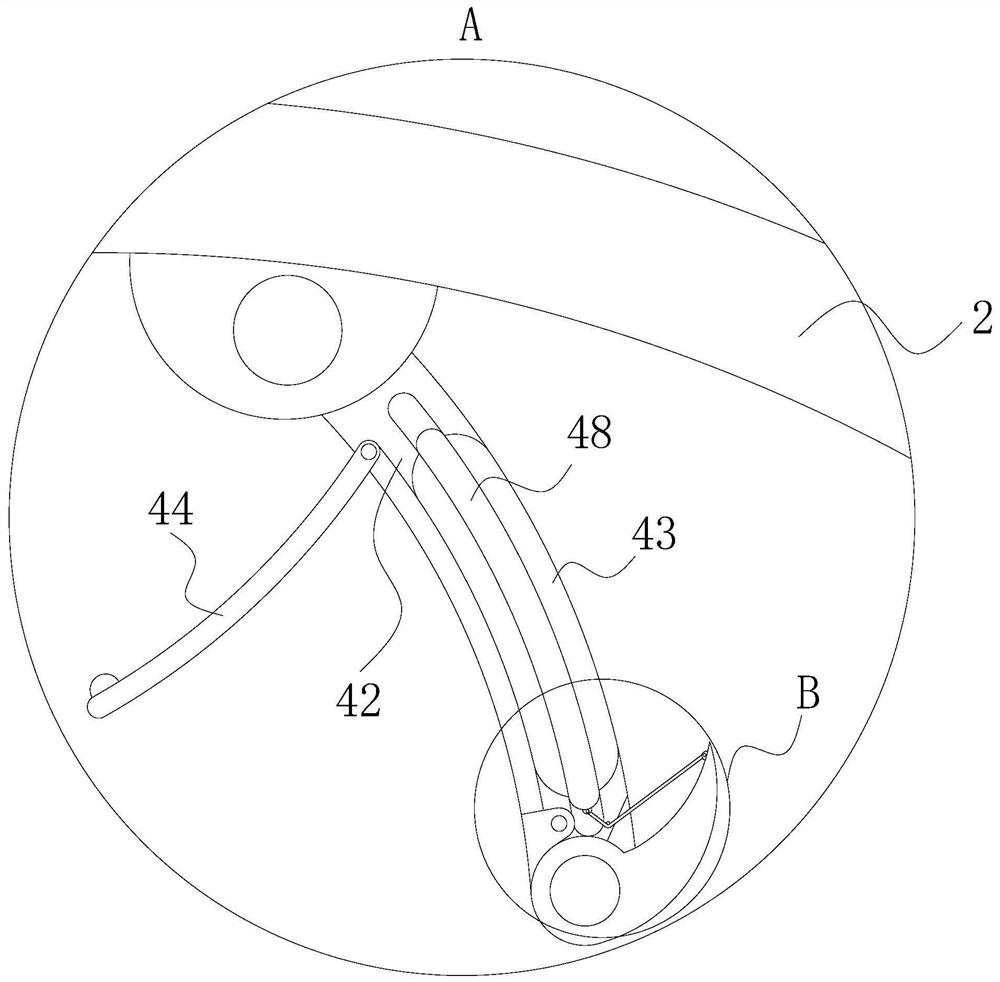

[0019] use Figure 1-Figure 4 A dessert processing device according to one embodiment of the present invention will be described as follows.

[0020] Such as Figure 1-Figure 4 As shown, a kind of dessert processing device according to the present invention includes a body 1, a processing chamber 2, a motor 3 and a stirring mechanism 4; the upper surface of the front end of the body 1 is fixedly equipped with a processing chamber 2; The cross section is U-shaped, and the inside of the processing chamber 2 is provided with a stirring mechanism 4; the stirring mechanism 4 includes a stirring rod 41, a hinged plate 42, a filter screen 43, a rotating plate 44, a cutting block 45, a pushing block 46, and a pull cord 47 and a dislocation plate 48; the stirring rod 41 is initially set to an arc shape, and there are multiple stirring rods 41, and the stirring rod 41 is arranged around the circumference, and the stirring rod 41 is made of elastic memory metal material, and the upper e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com