Novel bag type expansion body anti-pulling anchor rod and construction method thereof

An anti-pull anchor and capsule technology, which is applied in foundation structure engineering, sheet pile walls, protection devices, etc., can solve problems such as the inability to guarantee the safety of foundation pit support, difficult control of construction quality, and inaccurate calculation of anchoring force. , to achieve the effect of simple and clear bearing mechanism, simple construction quality control, and shortened construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

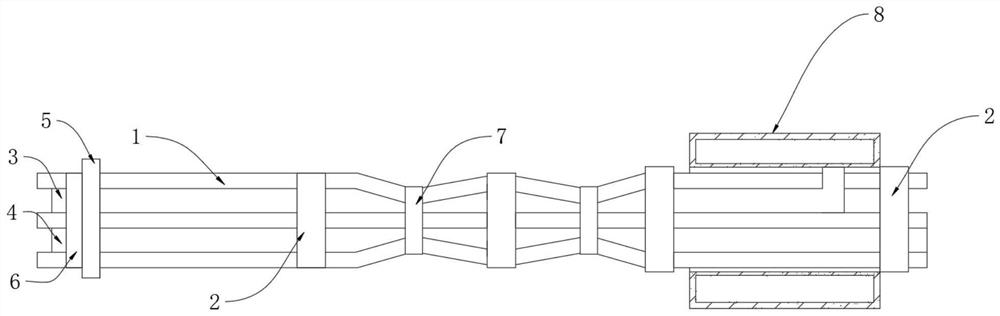

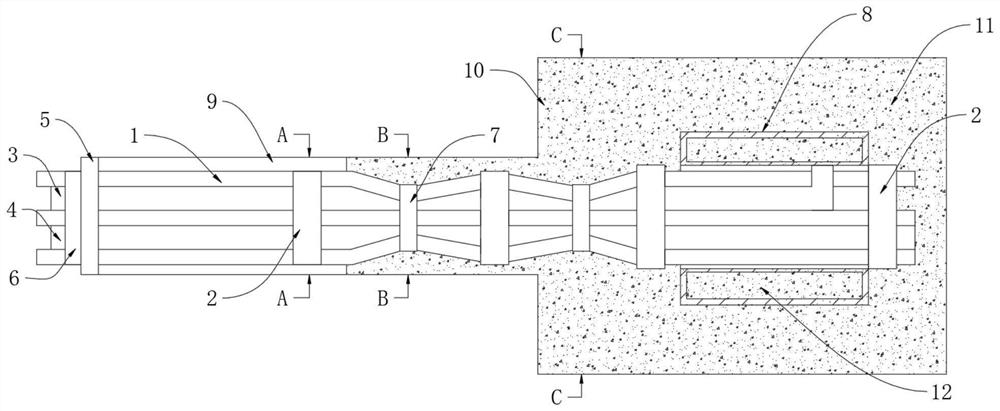

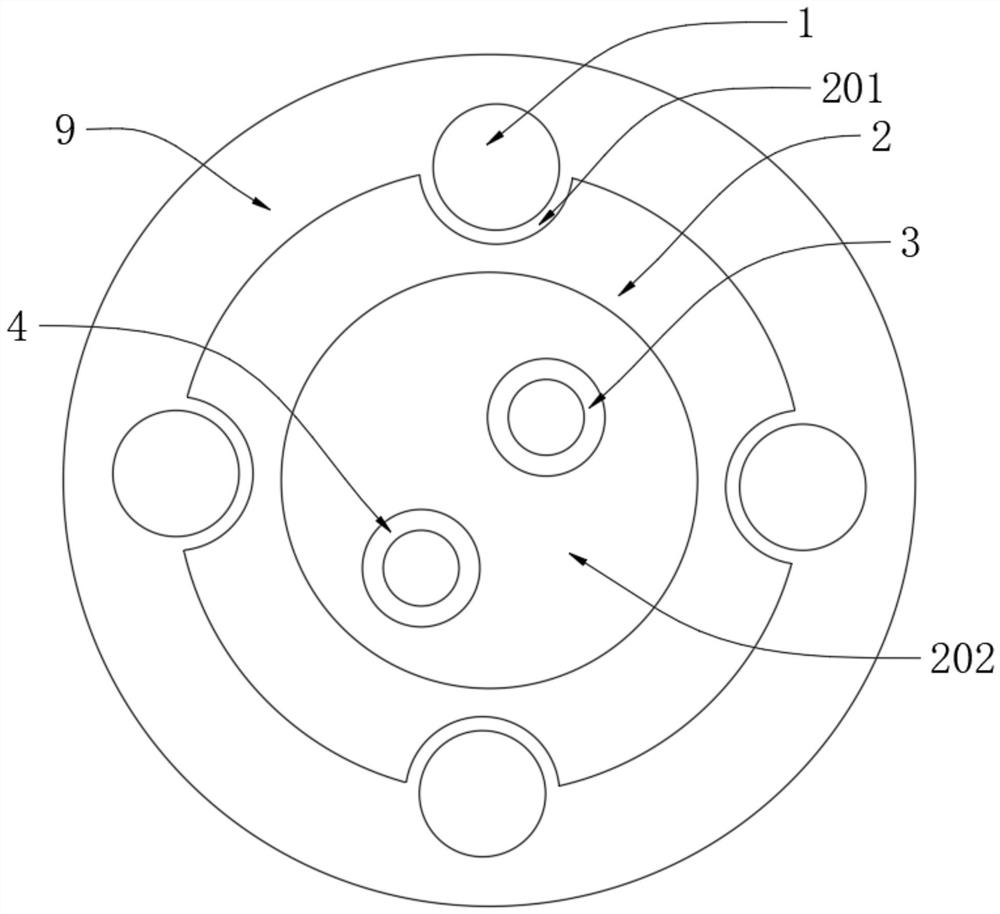

[0050] Refer to attached Figure 1-6 As shown in the figure, the new capsule-type expanded body pullout anchor includes steel strand 1, centering bracket 2, intra-capsular grouting pipe 3, outer-capsular grouting pipe 4, anchor plate 5, anchorage 6, and hoop ring 7 and a pressure-bearing capsule 8, the surface of the centering bracket 2 is provided with a first through groove 201 and a second through groove 202 from outside to inside, and the surface of the anchor plate 5 is provided with a first through groove from outside to inside. A through hole 501 and a second through hole 502, the first through hole 501 and the second through hole 502 are used to respectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com