Integrally fabricated waterproof shower room

A prefabricated shower room technology, applied in small buildings, building components, building insulation materials, etc., can solve the problems of water seepage and repair in the bathroom, difficulty in drainage slope construction, difficulty in meeting consumer demand, etc., and achieve reliable drainage system Advanced, reduced construction procedures, enriched functional design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

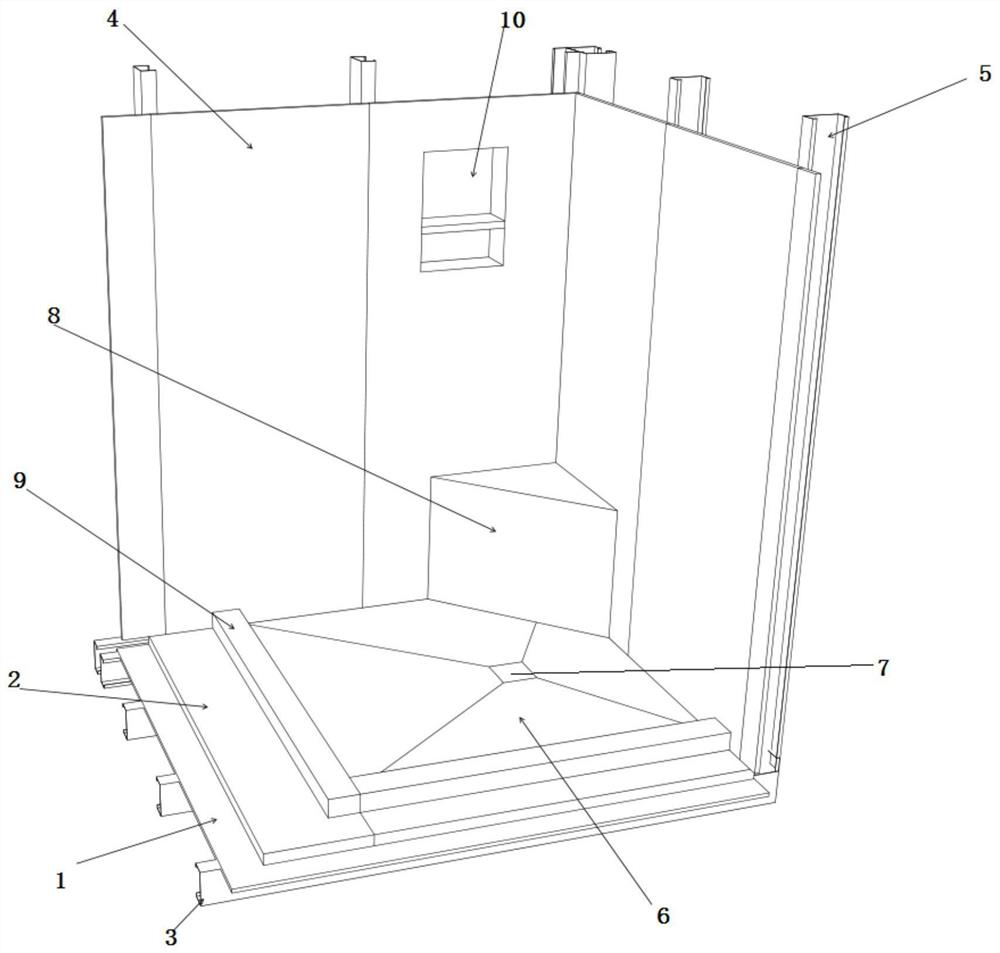

[0023] refer to Figure 1-Figure 7 , the present invention proposes an integrally assembled waterproof shower room, including a floor and a plurality of wall panels; wherein:

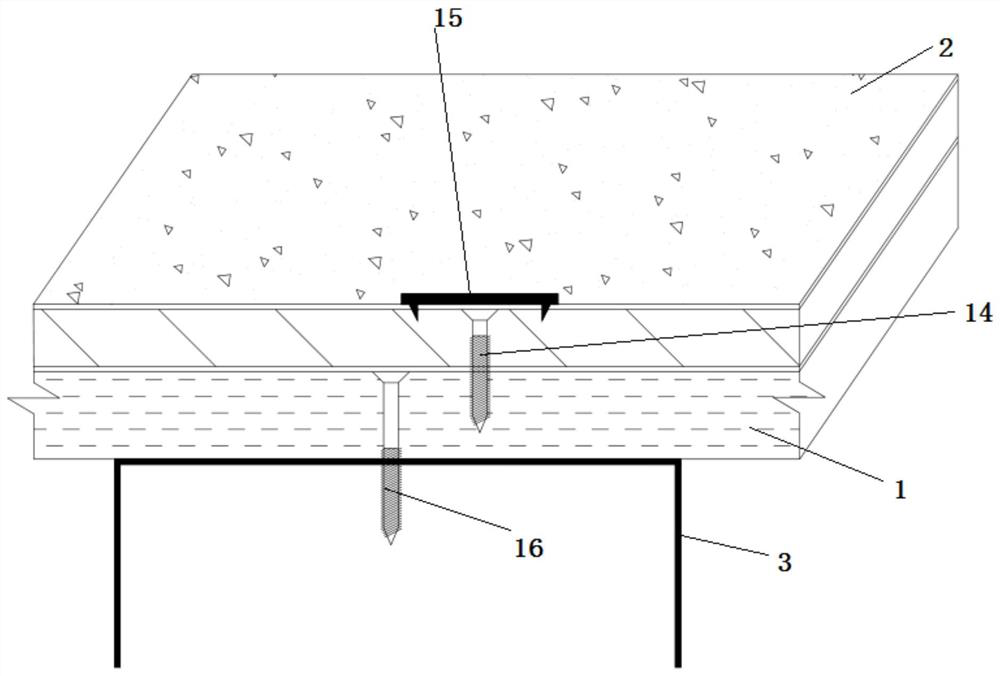

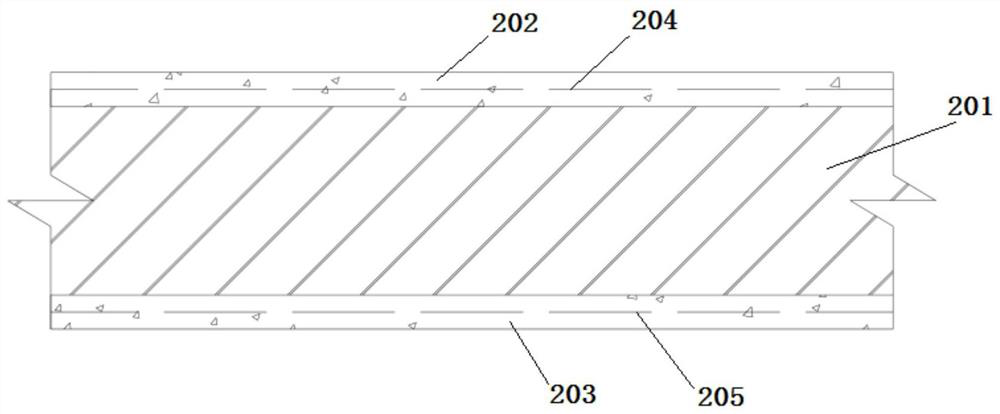

[0024] The floor is arranged horizontally. The floor includes OSB board 1 and floor panel 2. The top surface of the floor panel 2 is provided with a ground waterproof layer. The top of the OSB board 1 and the ground board 2 are fixedly connected with the OSB board 1 , and the bottom end of the OSB board 1 is fixedly connected with a plurality of horizontally arranged first light steel keels 3 .

[0025] The ground panel 2 is provided with a drainage area 6, and the drainage area 6 is provided with a drain outlet 7, and a floor drain is installed in the drain outlet 7, and the drainage area 6 is provided with a slope inclined to the drain outlet 7, so as to facilitate drainage. The shower stool 8 is made of XPS composite board in the drainage area 6 , and the water stop strip 9 installed on the floor pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com