A kind of inert gas protection method when explosion-proof lithium battery power supply burns

A technology of inert gas and lithium batteries, which is applied in the direction of electrical components, battery pack components, batteries and their environment isolation, etc., and can solve problems such as damage to surrounding equipment, safety accidents, and damage to flameproof enclosures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

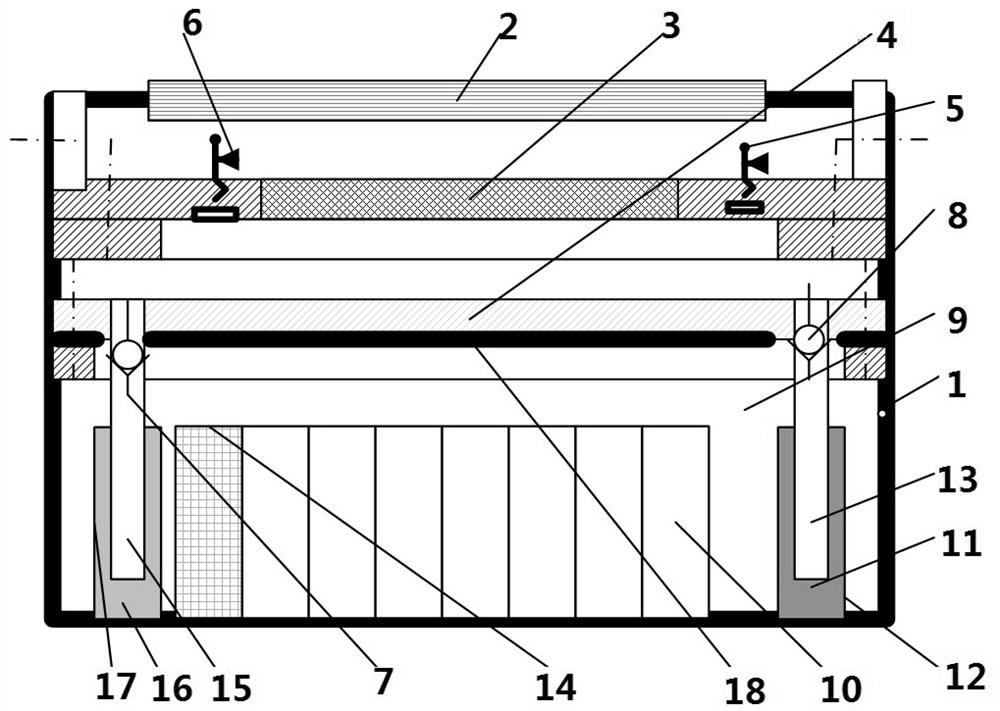

Method used

Image

Examples

Embodiment 1

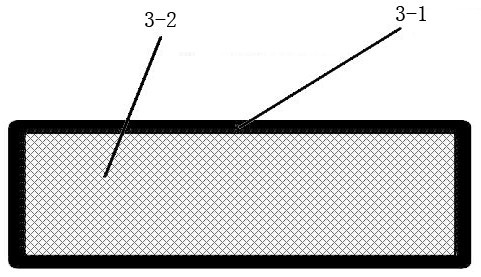

[0030] Embodiment 1, refer to the attached figure 2 , the flame arrester 3 is a corrugated flame arrester, which is composed of a flame arrester frame 1 3-1 and a multi-layer flame arrester mesh 3-2. The multilayer flame arrester mesh 3-2 is set in the flame arrester frame 1 3-1. A 3-1 is fixed on the side wall of the battery box 1 .

Embodiment 2

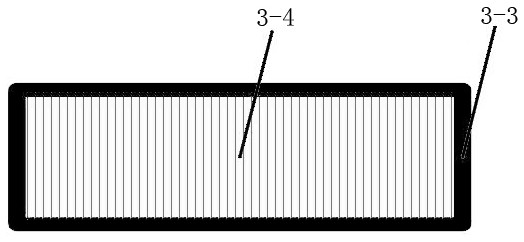

[0031] Embodiment 2, refer to the attached image 3 , the flame arrester 3 is an explosion-proof flat flame arrester, which is composed of a flame arrester frame 2 3-3 and a plurality of flame arrester sheets 3-4. The multiple flame arrester sheets 3-4 are arranged in the flame arrester frame 2 3-3. The second firearm frame 3 - 3 is fixed on the side wall of the battery box 1 .

[0032] The battery box 1 is made of metal steel plate or plastic with a certain strength. Since the battery box 1 is designed not to bear pressure or slight pressure inside, the shell is light in weight and the energy-to-weight ratio of the battery pack is increased.

[0033] The battery pack 10 of the present invention is installed in a closed space filled with inert gas. The function of the inert gas 9 is: when the battery pack 10 is burned and exploded due to external factors such as overcharge and overdischarge, the battery pack 10 is in a state of isolating oxygen, reducing the , destroy or weak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com