Catalyst impregnation device and impregnation method using same

A technology of impregnation device and catalyst, which is applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalyst, etc., can solve the problem of uneven distribution of catalyst active components, low active component loading, and lack of impregnation process control. and other problems, to achieve the effect of uniform distribution of active components and stable content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

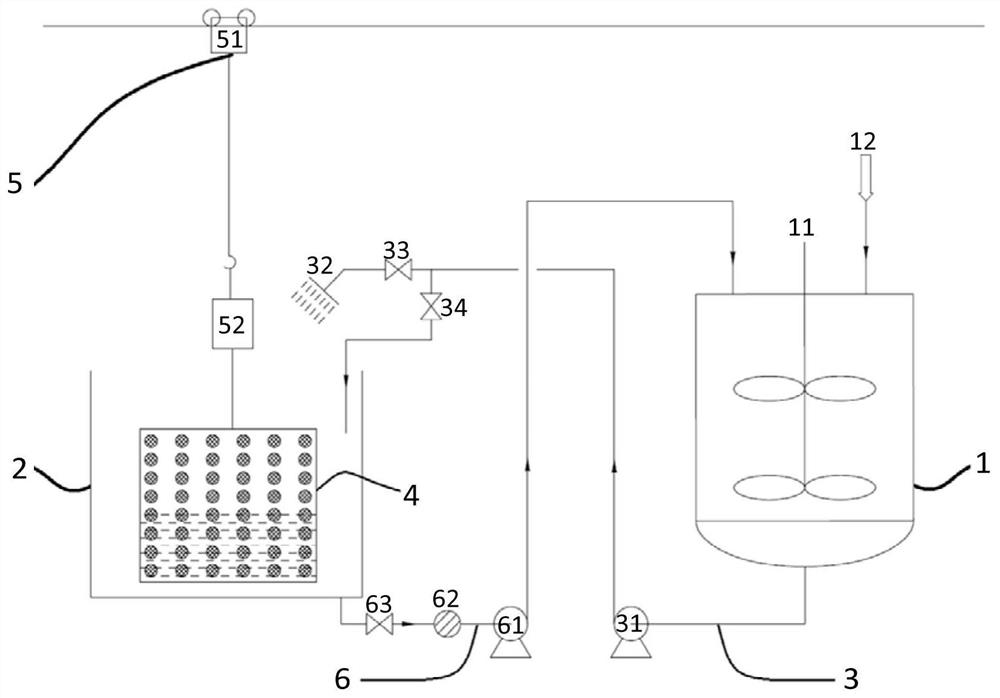

Method used

Image

Examples

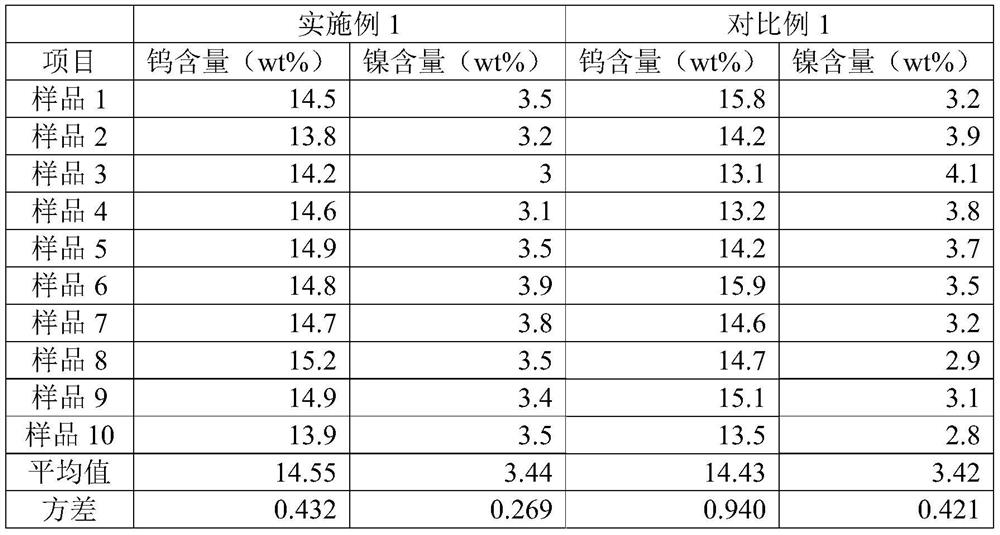

Embodiment 1

[0061] 1) Add 1000L of pure water into the impregnating liquid storage tank 1 through the feeding port 12, start the agitator 11 for stirring, add 200 kg of ammonium metatungstate (ammonium metatungstate with a tungsten oxide content of 82 wt%) and continue stirring for 10 minutes, Add 250 kg of nickel nitrate (nickel nitrate with a nickel oxide content of 24 wt%), stir for 10 min after the addition, replenish the solution to 1500 L, and stir for 30 min.

[0062] 2) Put the catalyst carrier to be impregnated into the carrier barrel 4 (the input amount of the carrier is 1 / 2 of the volume of the carrier barrel). The carrier barrel 4 is hoisted into the dipping tank 2 by means of an electric hoist.

[0063] 3) Turn on the delivery pump 31, pump the impregnating liquid in the impregnating liquid storage tank 1 into the impregnating tank 2, turn on the rotating motor, and make the rotation speed of the carrier barrel 4 be 15 rpm. When the immersion liquid in the immersion tank 2 r...

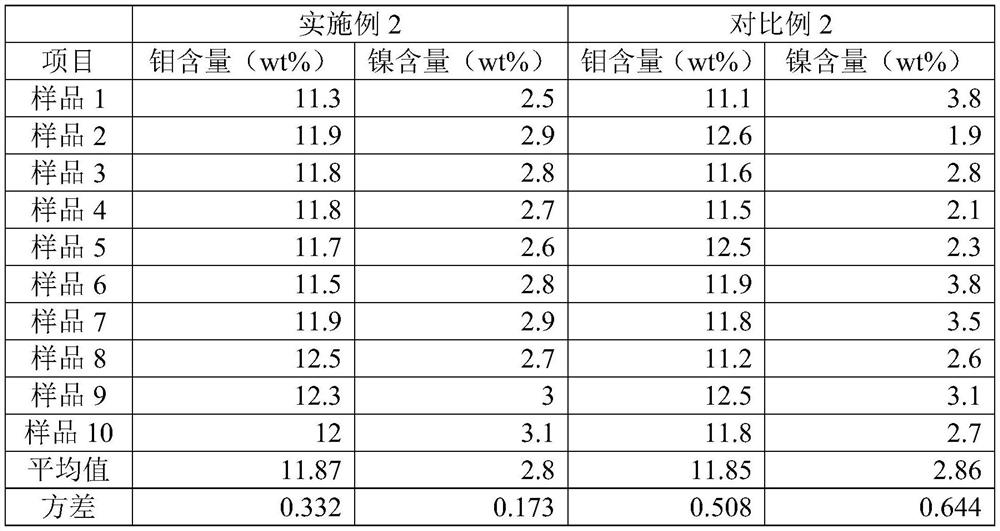

Embodiment 2

[0069] 1) Add 1000L of pure water into the impregnating liquid storage tank 1 through the feeding port 12, start the agitator 11 for stirring, add 175 kg of molybdenum trioxide (molybdenum trioxide with a molybdenum oxide content of 99 wt%), continue stirring for 10 minutes, and add nitric acid Nickel (nickel nitrate with a nickel oxide content of 24wt%) was stirred for 10 minutes after the addition; the solution was replenished to 1500 L and stirred for 20 minutes.

[0070] 2) Put 600 kg of catalyst carrier to be impregnated into the carrier barrel 4 (the input amount of the carrier is 2 / 3 of the volume of the carrier barrel). The carrier bucket is hoisted into the impregnation tank 2 by means of an electric hoist. Turn on the rotating motor to make the carrier barrel rotate. The number of revolutions of the carrier barrel is 10 revolutions / min.

[0071] 3) Turn on the delivery pump 31, pump the impregnating liquid in the impregnating liquid storage tank 1 into the impregna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com