PVC floor film surface dust removal device

A technology of dust removal device and floor, which is applied in the direction of removing smoke and dust, cleaning method using gas flow, cleaning hollow objects, etc. The effect of increasing the dust removal area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

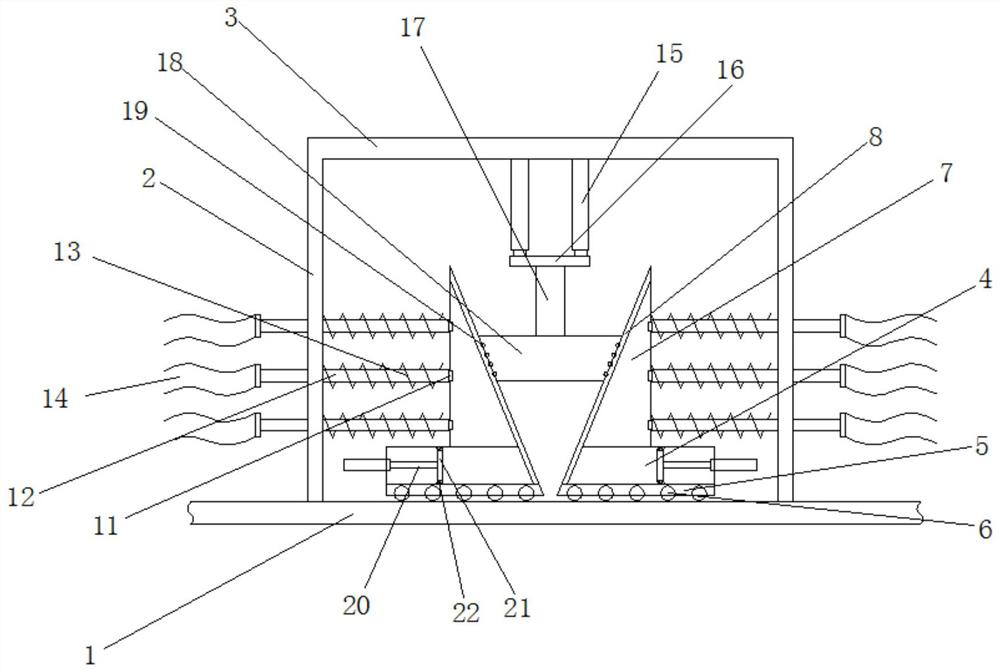

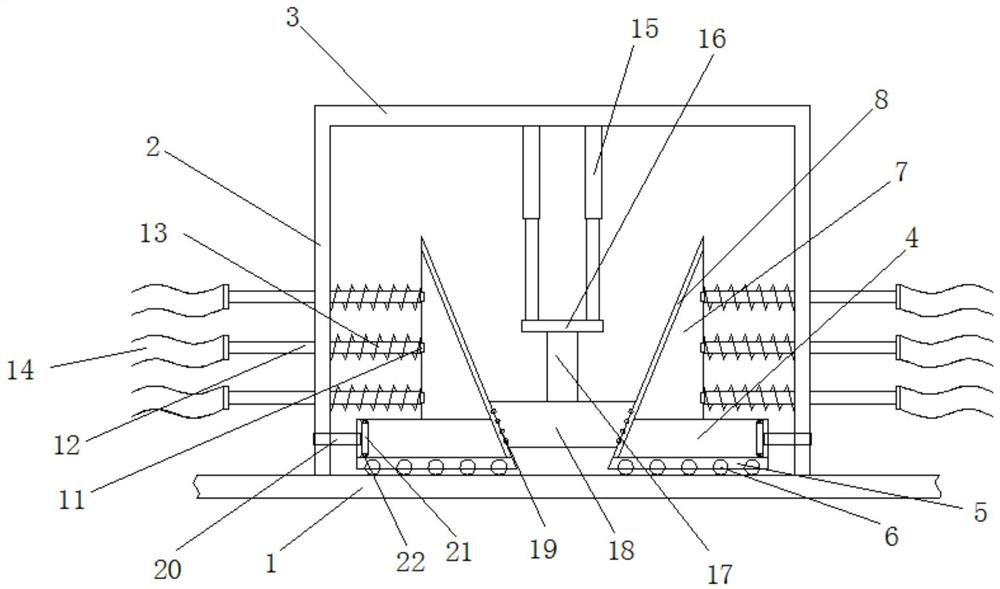

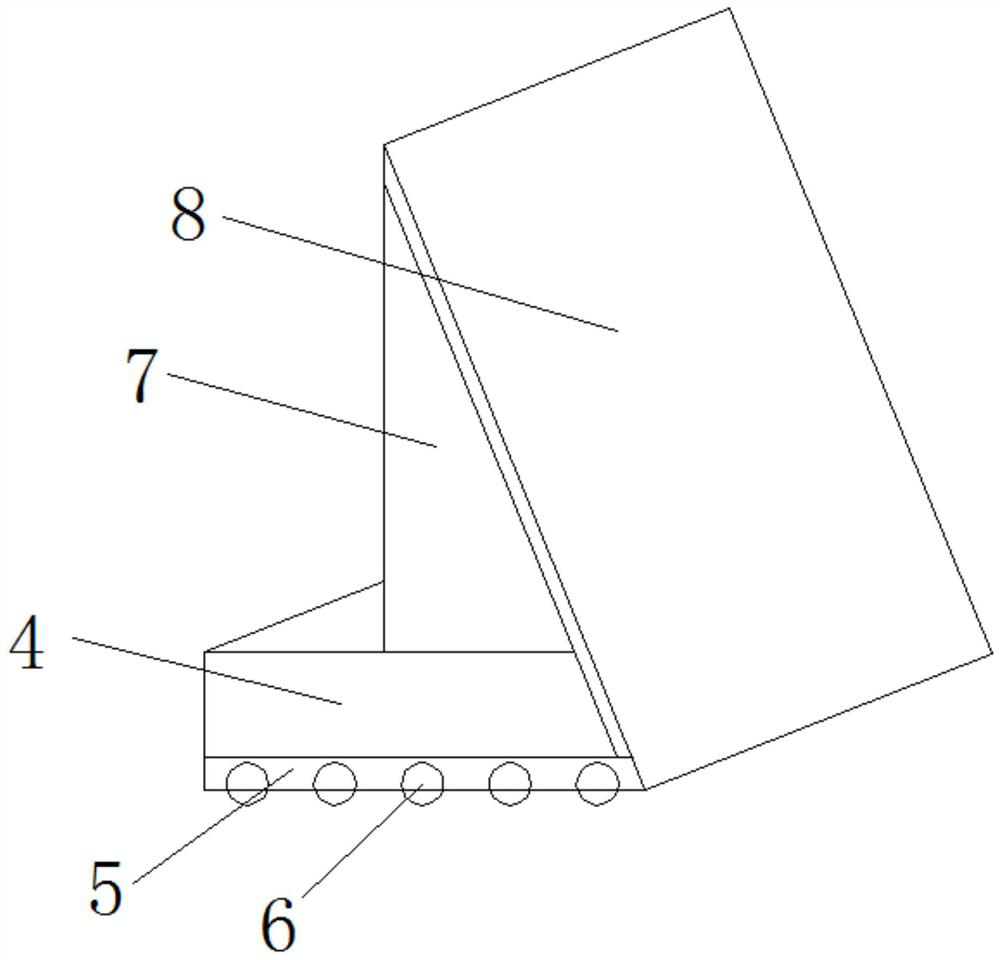

[0029] Embodiment 1: as Figure 1-5 As shown, a surface dust removal device for a PVC floor film includes a conveyor 1 and a dust collection bin 4. The dust collection bin 4 is provided with two groups, and the tops of both sides of the conveyor 1 are fixedly connected with brackets 2. A beam frame 3 is fixedly connected between the tops of the two groups of brackets 2;

[0030] The two groups of dust collection bins 4 are located above the conveyor 1, and both sides of the bottom of the two groups of dust collection bins 4 are fixedly equipped with mounting frames 5, and the mounting frames 5 of the two groups have built-in cavities. There are a number of dust suction rollers 6 that are rotatably connected between the inner walls of the mounting frame 5, and each set of the dust suction rollers 6 has a built-in cavity, and the side walls of each set of the dust suction rollers 6 are provided with a number of through holes 9. The first fan 10 is fixedly installed in the mount...

Embodiment 2

[0040] Embodiment 2: as Figure 1-5 As shown, a surface dust removal device for a PVC floor film includes a conveyor 1 and a dust collection bin 4. The dust collection bin 4 is provided with two groups, and the tops of both sides of the conveyor 1 are fixedly connected with brackets 2. A beam frame 3 is fixedly connected between the tops of the two groups of brackets 2;

[0041]The two groups of dust collection bins 4 are located above the conveyor 1, and both sides of the bottom of the two groups of dust collection bins 4 are fixedly equipped with mounting frames 5, and the mounting frames 5 of the two groups have built-in cavities. There are a number of dust suction rollers 6 that are rotatably connected between the inner walls of the mounting frame 5, and each set of the dust suction rollers 6 has a built-in cavity, and the side walls of each set of the dust suction rollers 6 are provided with a number of through holes 9. The first fan 10 is fixedly installed in the mounti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com