Efficient shot blasting machine driven by electromagnetism

An electromagnetic drive and shot blasting machine technology, applied in the field of polishing machines, can solve problems such as energy waste and poor processing results, and achieve the effects of reducing consumption, improving practicability, and facilitating control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

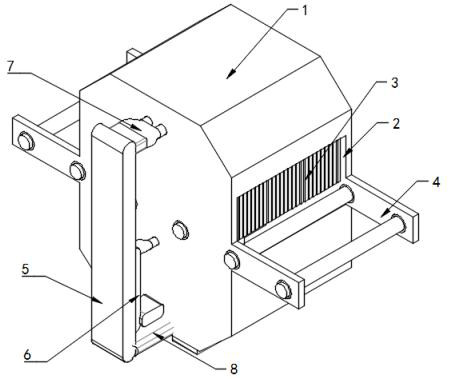

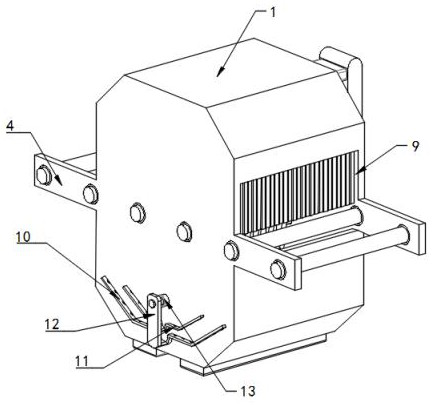

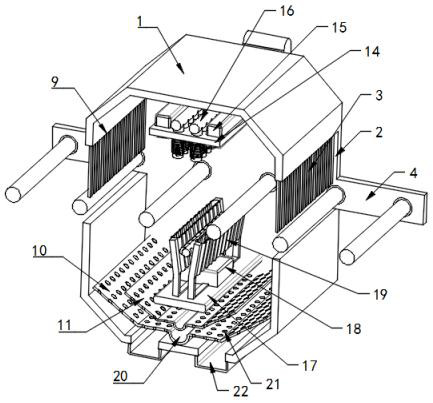

[0040] Example 1, please refer to Figure 1-8 , a high-efficiency shot blasting machine using electromagnetic drive, including a box body 1, the two sides of the box body 1 are respectively provided with a discharge port 2 and a material inlet 9, and there is a gap between the discharge port 2 and the material inlet 9 Conveyor table 4, and the discharge port 2 and the feed port 9 are provided with curtains 3, the inside of the box body 1 is respectively provided with an upper shot blasting mechanism 14 and a lower shot blasting mechanism 17, and the upper shot blasting mechanism 14 and the lower shot blasting mechanism Multiple shot blasting mechanisms 17 can be set, and the positions are staggered to ensure that they will not have a large impact on each other;

[0041] Two groups of shot blasting tubes 32 are fixedly connected to the upper blasting mechanism 14, and coils 33 are wound around the two groups of shot blasting tubes 32. There is a first capacitor 15, and the fir...

Embodiment 2

[0045] Example 2, please refer to Figure 1-8 , a high-efficiency shot blasting machine using electromagnetic drive, including a box body 1, the two sides of the box body 1 are respectively provided with a discharge port 2 and a material inlet 9, and there is a gap between the discharge port 2 and the material inlet 9 Conveyor table 4, and the discharge port 2 and the feed port 9 are provided with blinds 3, and the inside of the box body 1 is respectively provided with an upper shot blasting mechanism 14 and a lower shot blasting mechanism 17;

[0046] Two groups of shot blasting pipes 32 are fixedly connected on the upper shot blasting mechanism 14, and coils 33 are all wound on the two groups of shot blasting pipes 32, and a first capacitor 15 is arranged on the upper shot blasting mechanism 14, and the first capacitor 15 and The coils 33 are electrically connected, and the shot blasting tube 32 is communicated with a connecting tube 16;

[0047] The middle position of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com