Extensible plane joint type robot

A technology of plane joints and robots, applied in the field of robots, can solve problems such as difficulty in adapting to the diversified production of enterprises and inability to work in different workspaces.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

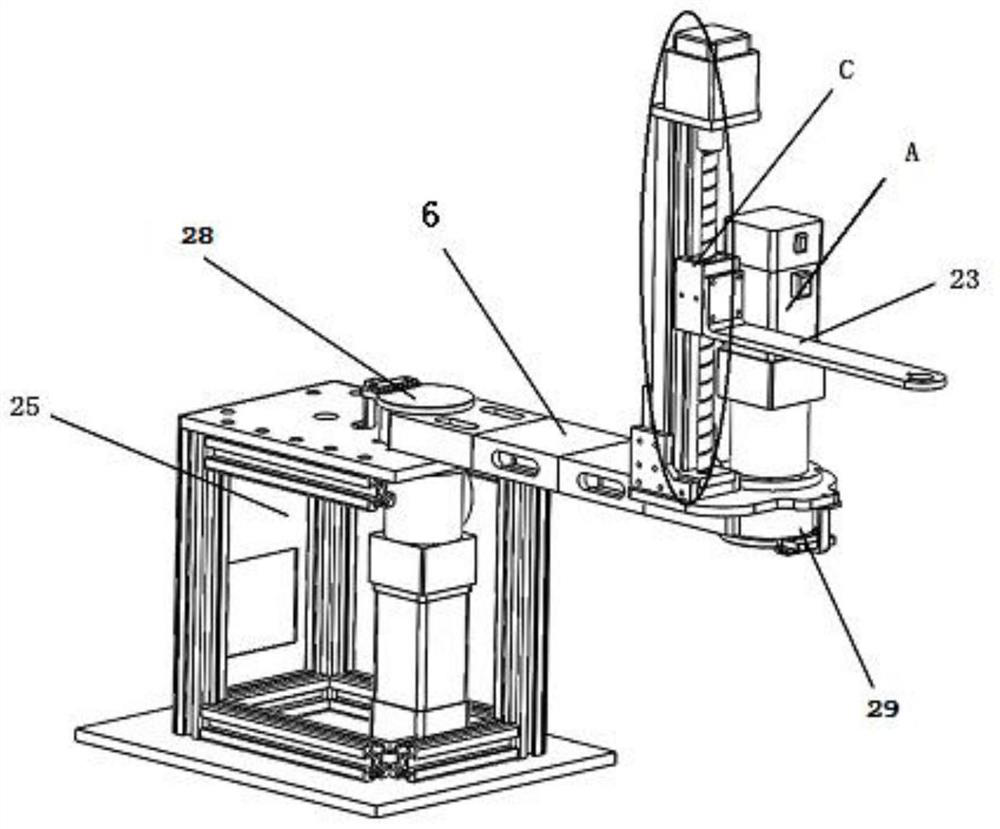

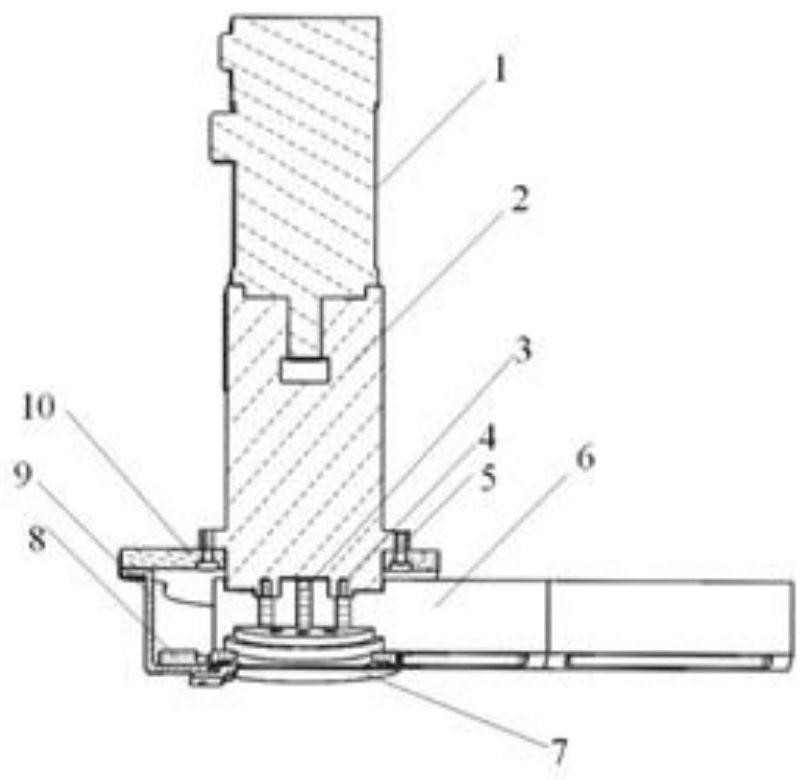

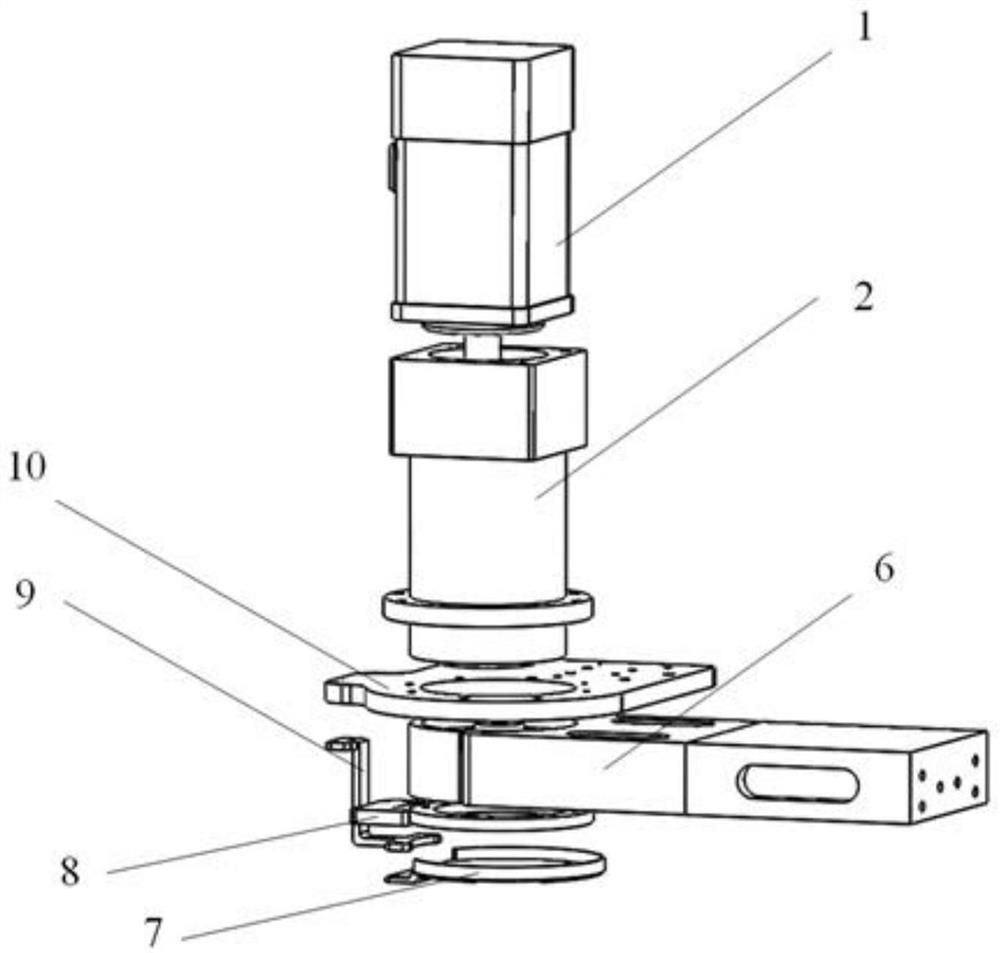

[0030] Such as Figure 1-Figure 7 As shown, an expandable planar articulated robot is provided. The present invention mainly includes a joint motor 1, a flange type planetary reducer 2, a rotating flange 4, an external boss 5, an encoder protection end cover 7, and a magnetic ring type angle encoder. 8. Encoder mounting bracket 9, reducer mounting platform 10, boom end module 11, boom middle module 12, boom front module 13, first joint reducer mounting hole 14, boom module bolt mounting hole 15, reinforcement Rib 16, hollow structure 17, first joint reducer installation hole 18, stepper motor 19, guide rail 20, lead screw 21, slider 22, robot arm 23, mounting bracket 24, base 25, first joint reducer The installation platform 27; the invention can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com