In-situ 3D printing cartilage repair device and method

A cartilage repair and 3D printing technology, which is applied in the field of additive manufacturing, can solve problems such as the inability to meet the complex environment and the inability to guarantee the accuracy of repair, and achieve the effects of short manual intervention time, fast printing speed, and easy storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

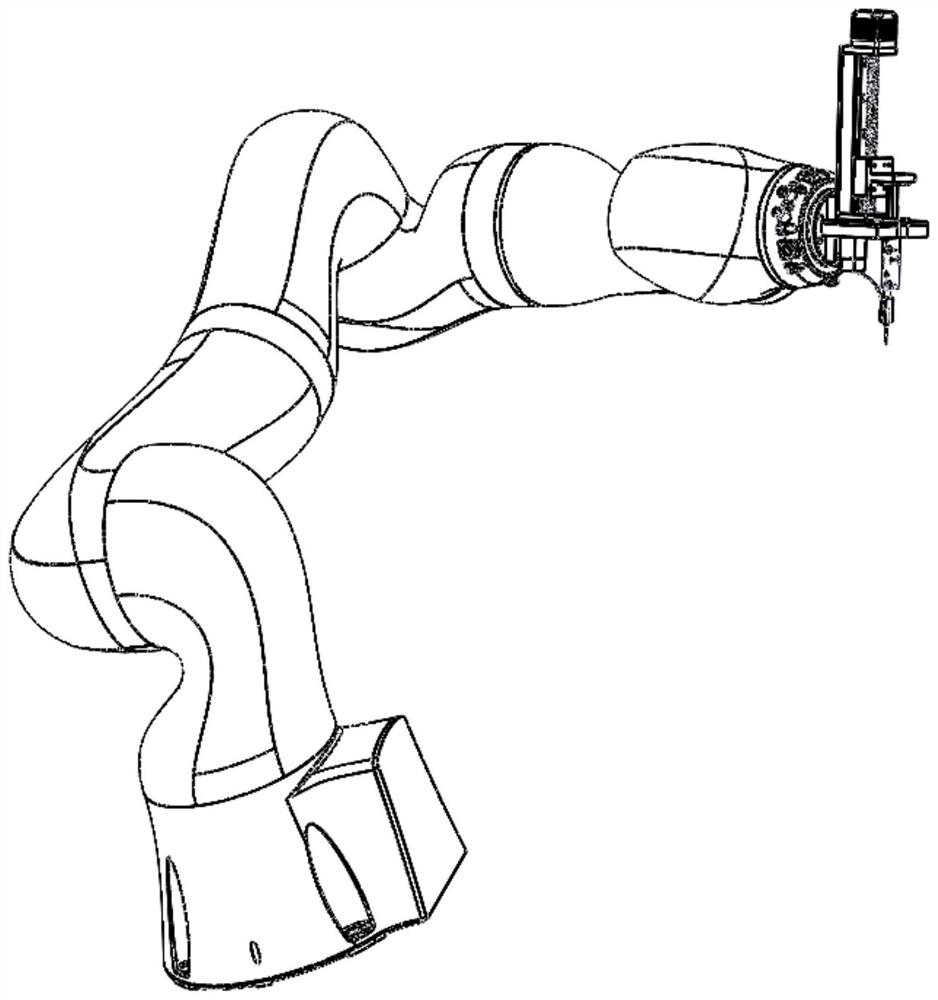

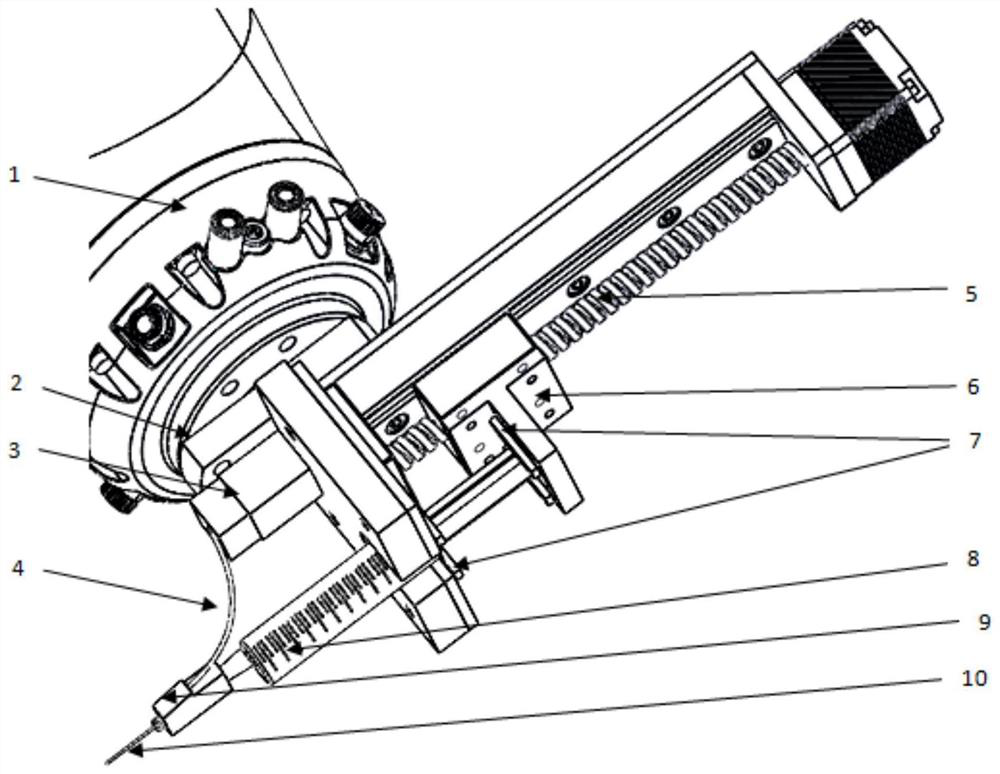

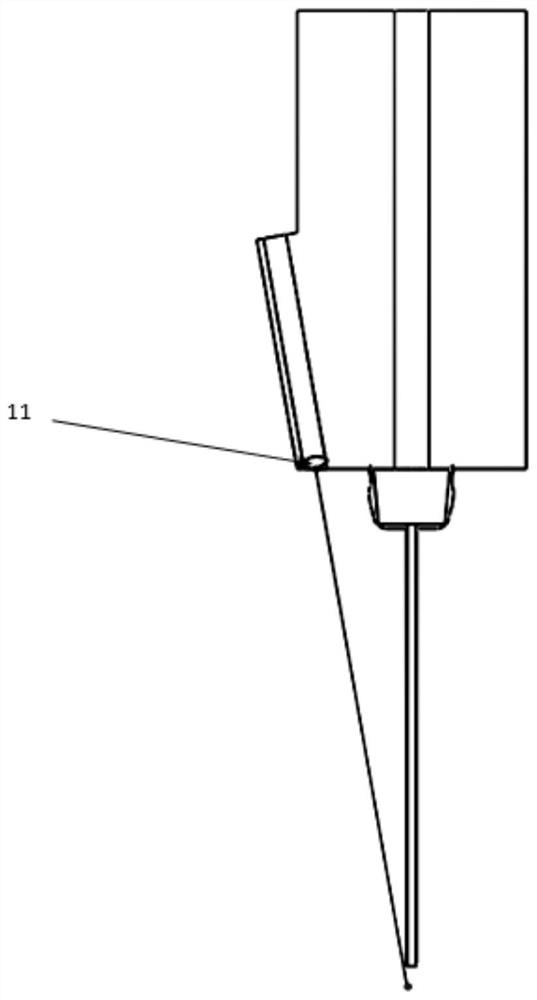

[0034] Such as figure 1 , figure 2 as well as image 3 As shown, the present invention is an in-situ 3D printing cartilage repair device, including a mechanical arm 1, an adapter frame 2, a blue light source 3, an optical fiber 4, a module 5, a pushing plate 6, a pressing plate 7, a syringe 8, and a three-way head 9. The injection needle 10 and the lens 11, the lens 11 is fixed inside the tee head 9 through a U-shaped slot, the tee head 9 is threaded to the optical fiber 4, and the optical fiber 4 is threaded to the blue light source 3 , the blue light source 3 is connected to the adapter frame 2 through bolts, the module 5 is connected to the adapter frame 2 through bolts and nuts, the push plate 6 is connected to the module 5 through bolts and nuts, and the syringe 8 is connected to the adapter frame 2 through bolts and nuts. The module is connected by a pressure plate 7, the injection needle 10 is connected to the syringe 8 by threads, the adapter frame 2 is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com