Preparation method of cobalt-nitrogen co-doped carbon nanocage

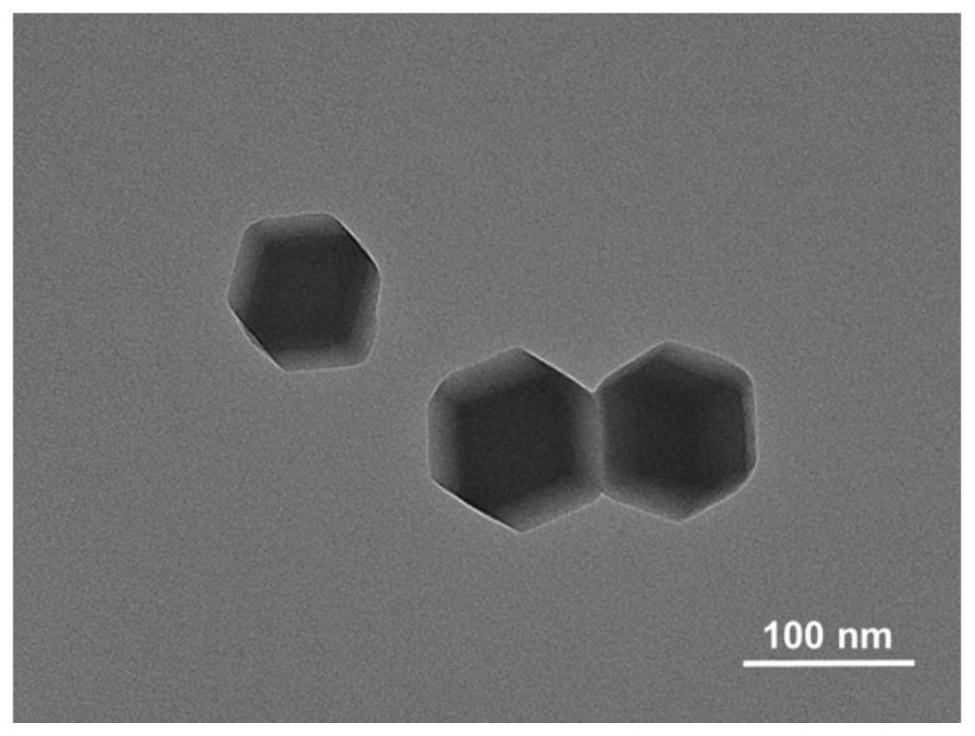

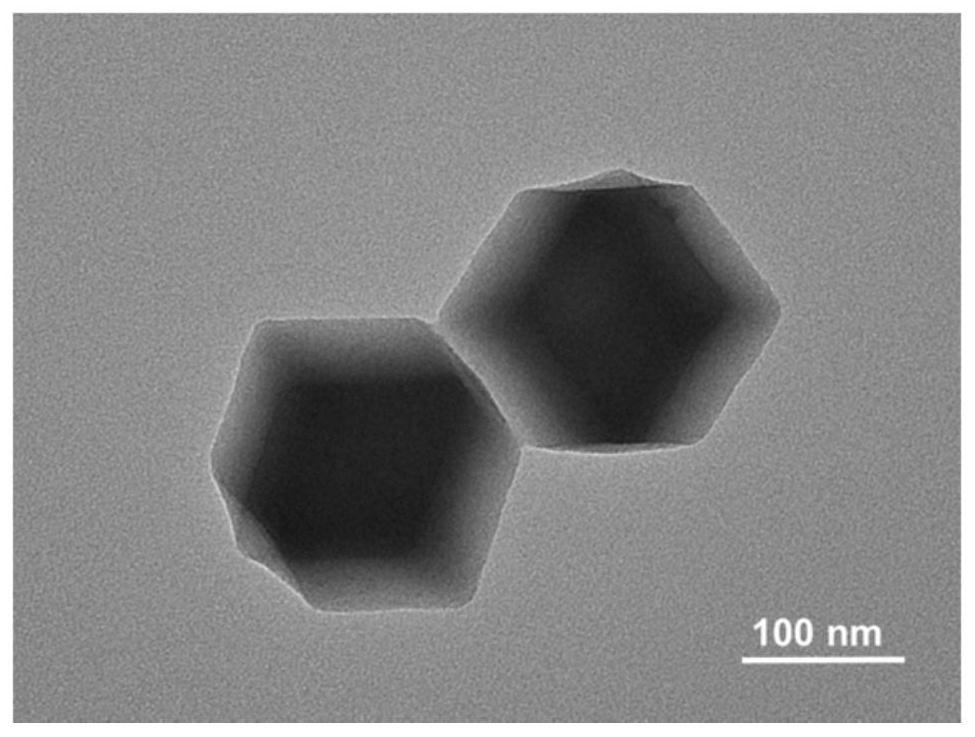

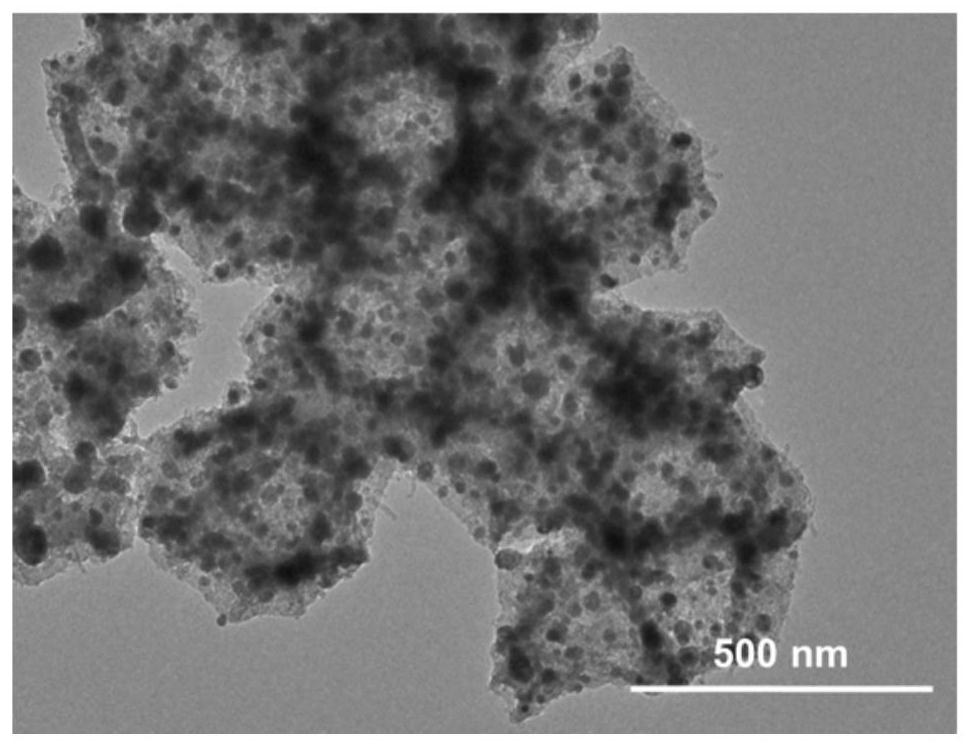

A carbon nanocage and co-doping technology, which is applied in the direction of nano-carbon, medical preparations of non-active ingredients, pharmaceutical formulas, etc., can solve problems such as unstable performance, variable size, and unclear polyhedral structure, and achieve uniform particle size. Good reproducibility and good shape results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 2.38g (0.008mol) Zn(NO 3 ) 2 ·6H 2 O and 2.627g (0.032mol) 2-methylimidazole were respectively dispersed in 100mL of anhydrous methanol solution, Zn(NO 3 ) 2 ·6H 2 O methanol solution is placed on a magnetic stirrer and stirred at a stirring rate of 300r / min for 10min, and the methanol solution of 2-methylimidazole is poured into Zn(NO 3 ) 2 ·6H 2 O methanol solution, maintain a stirring rate of 300r / min and place it at 10°C for 30min. After the product is cross-centrifuged and washed with absolute ethanol and deionized water three times, the obtained precipitate is dispersed in anhydrous methanol with ultrasonic assistance to obtain 200mL The methanol solution of ZIF-8 was taken out, and 50 mL was taken out for use. 582mg (0.002mol) Co(NO 3 ) 2 ·6H 2 O and 656.8mg (0.008mol) 2-methylimidazole were respectively dispersed in 50mL of anhydrous methanol, and Co(NO 3 ) 2 ·6H 2 The methanol solution of O and the methanol solution of 2-methylimidazole were poured...

Embodiment 2

[0034] 2.38g (0.008mol) Zn(NO 3 ) 2 ·6H 2 O and 2.627g (0.032mol) 2-methylimidazole were respectively dispersed in 100mL of anhydrous methanol solution, Zn(NO 3 ) 2 ·6H 2 O methanol solution is placed on a magnetic stirrer and stirred at a stirring rate of 300r / min for 10min, and the methanol solution of 2-methylimidazole is poured into Zn(NO 3 ) 2 ·6H 2 O methanol solution, maintain a stirring rate of 300r / min and place it at 25°C for 30min to react for 30min. After the product is cross-centrifuged and washed with absolute ethanol and deionized water three times, the obtained precipitate is dispersed in anhydrous methanol with ultrasonic assistance to obtain 200mL The methanol solution of ZIF-8 was taken out, and 50 mL was taken out for use. 582mg (0.002mol) Co(NO 3 ) 2 ·6H 2 O and 656.8mg (0.008mol) 2-methylimidazole were respectively dispersed in 50mL of anhydrous methanol, and Co(NO 3 ) 2 ·6H 2 The methanol solution of O and the methanol solution of 2-methylim...

Embodiment 3

[0036] 2.38g (0.008mol) Zn(NO 3 ) 2 ·6H 2 O and 2.627g (0.032mol) 2-methylimidazole were respectively dispersed in 100mL of anhydrous methanol solution, Zn(NO 3 ) 2 ·6H 2 O methanol solution is placed on a magnetic stirrer and stirred at a stirring rate of 300r / min for 10min, and the methanol solution of 2-methylimidazole is poured into Zn(NO 3 ) 2 ·6H 2 O methanol solution, maintain a stirring rate of 300r / min and place it at 25°C for 1h. After the product is cross-centrifuged and washed with absolute ethanol and deionized water three times, the obtained precipitate is dispersed in anhydrous methanol with ultrasonic assistance to obtain 200mL The methanol solution of ZIF-8 was taken out, and 50 mL was taken out for use. 582mg (0.002mol) Co(NO 3 ) 2 ·6H 2 O and 656.8mg (0.008mol) 2-methylimidazole were respectively dispersed in 50mL of anhydrous methanol, and Co(NO 3 ) 2 ·6H 2 The methanol solution of O and the methanol solution of 2-methylimidazole were poured in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com