Multi-layer self-heating food heating bag and preparation method

A heating pack, food technology, applied in chemical instruments and methods, heat exchange materials, etc., can solve the problems of easy aggregation into blocks, long duration, insufficient internal heat release, etc., and achieve the effect of increasing the heat release time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

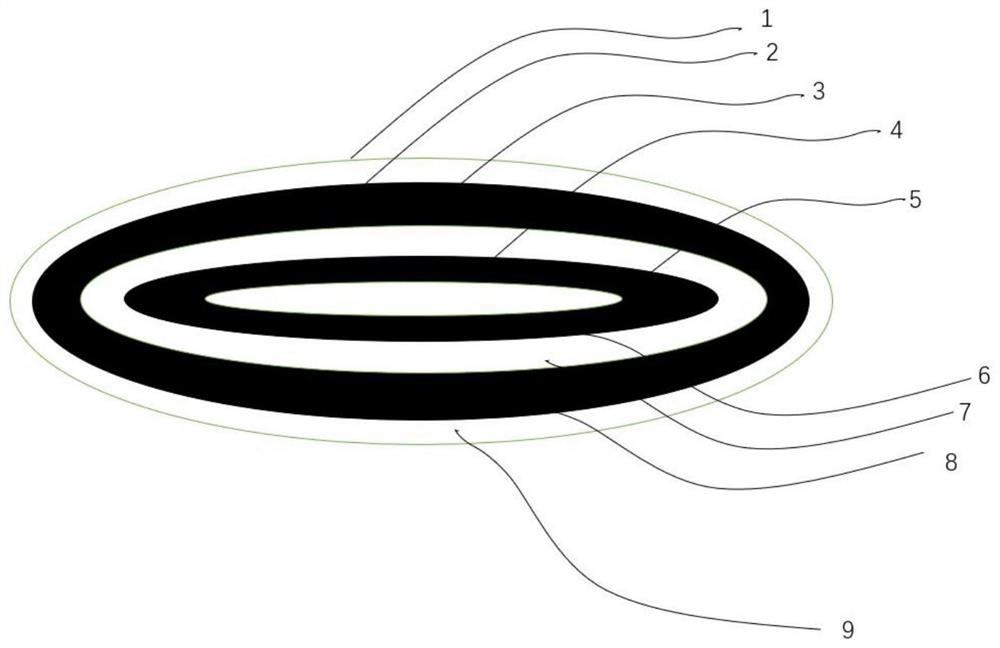

Image

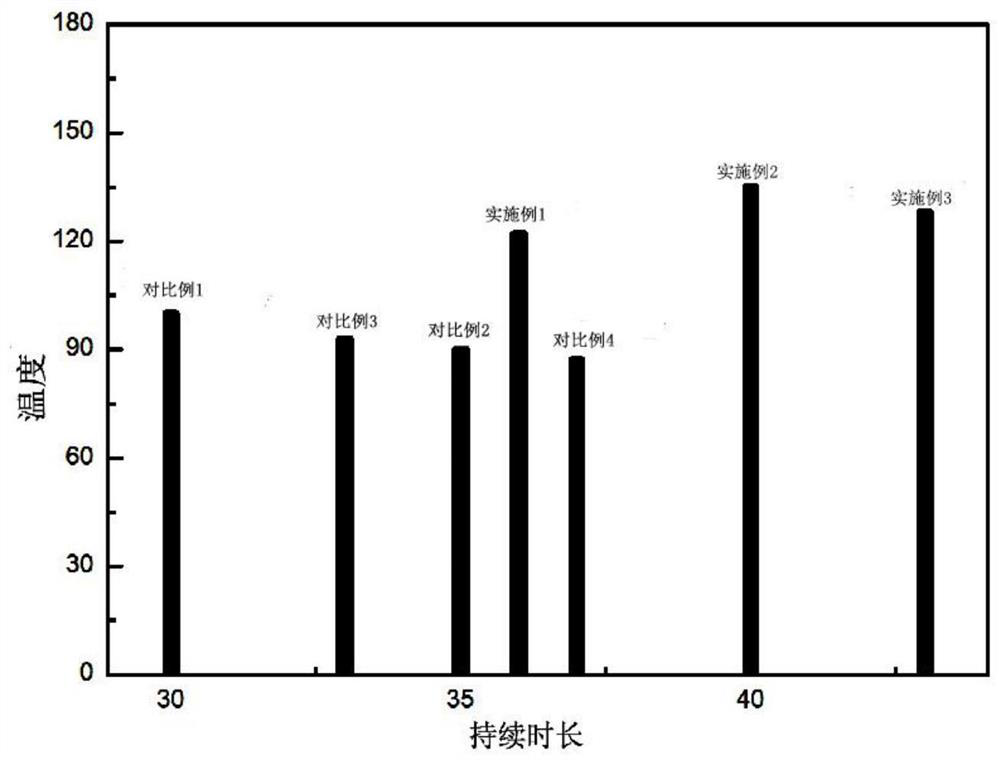

Examples

Embodiment 1

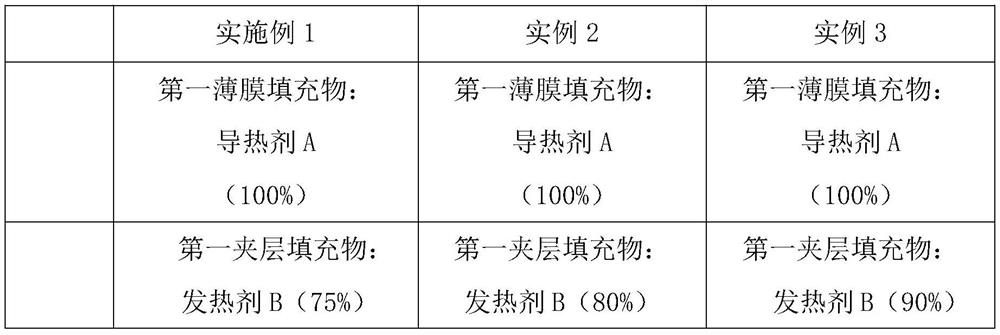

[0040] The preparation method of a kind of multi-layer self-heating food heating package provided by the present embodiment comprises the following steps:

[0041] 1) Wrap the heat-conducting agent A, the wrapping film is a microporous film, and the weight percentage of the heat-conducting agent is: 100%;

[0042] 2) The product of step 1) is wrapped for the second time, the wrapping film is a microporous film, the first interlayer is filled with exothermic agent A and heat conducting agent B, the content of exothermic agent B is 75% by weight, and the content of heat conducting agent A is 25%, the weight percentages of the exothermic agent B particle size gradation of 50 mesh, 100 mesh and 300 mesh are: 20%, 30%, 50%;

[0043] 3) Wrapping the product of step 2) for the third time, the wrapping film is a microporous film, and the second interlayer is filled with a heat conducting agent B and a hydrophilic agent, and the weight percentages of the heat conducting agent B and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com