Automatic crawling spraying machine and spraying method thereof

An automatic crawling and machine technology, applied in the direction of instruments, radio wave reflection/re-radiation, measuring devices, etc., can solve the problem of inability to adapt to large heights, high mobility and precise control, outdoor working environment, long preparation time, poor mobility, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

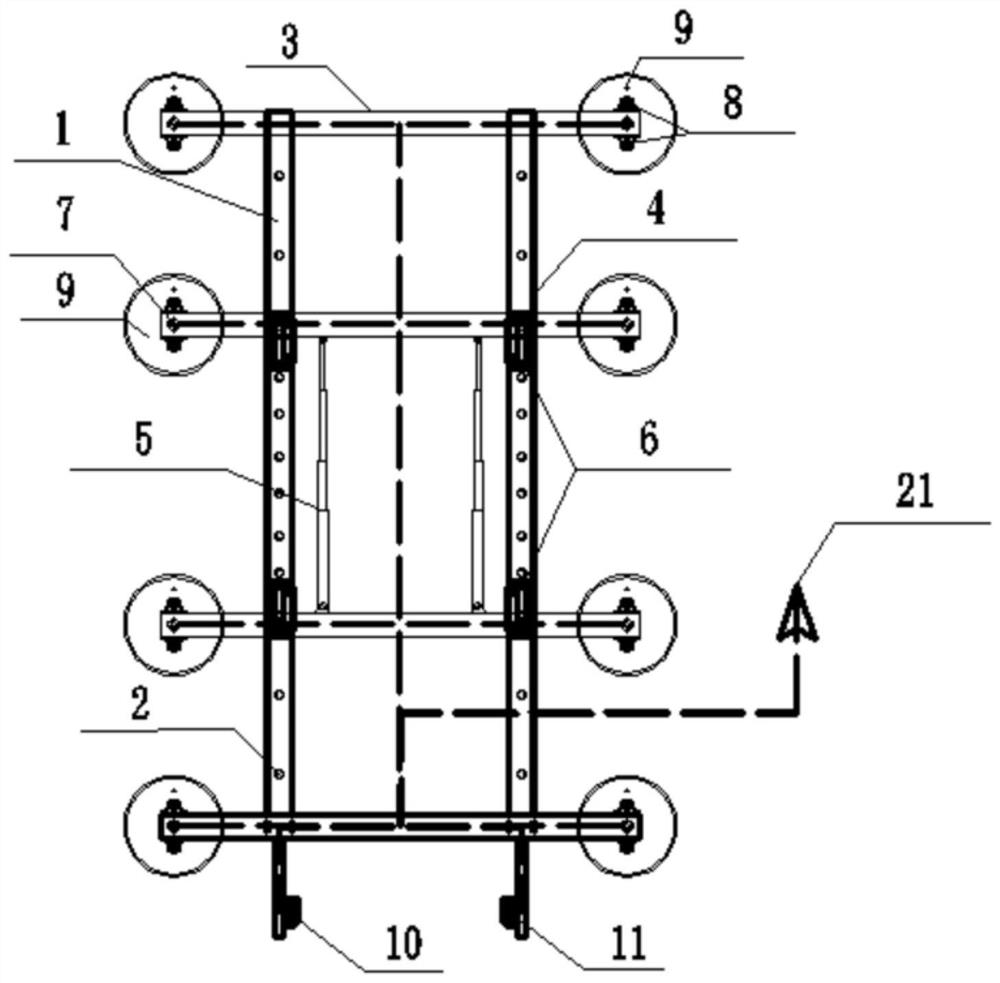

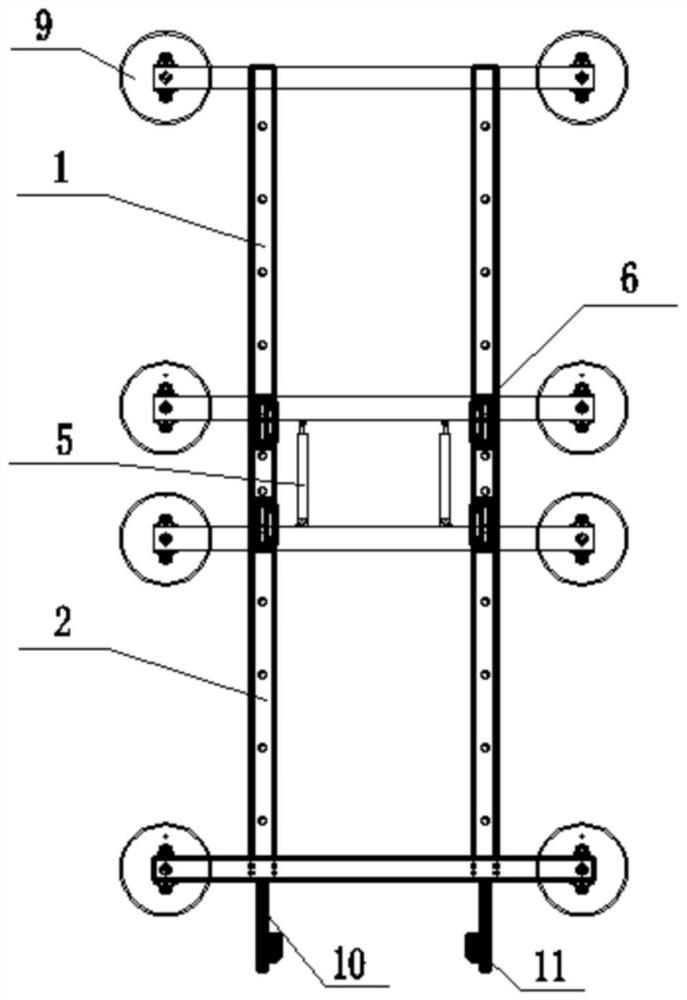

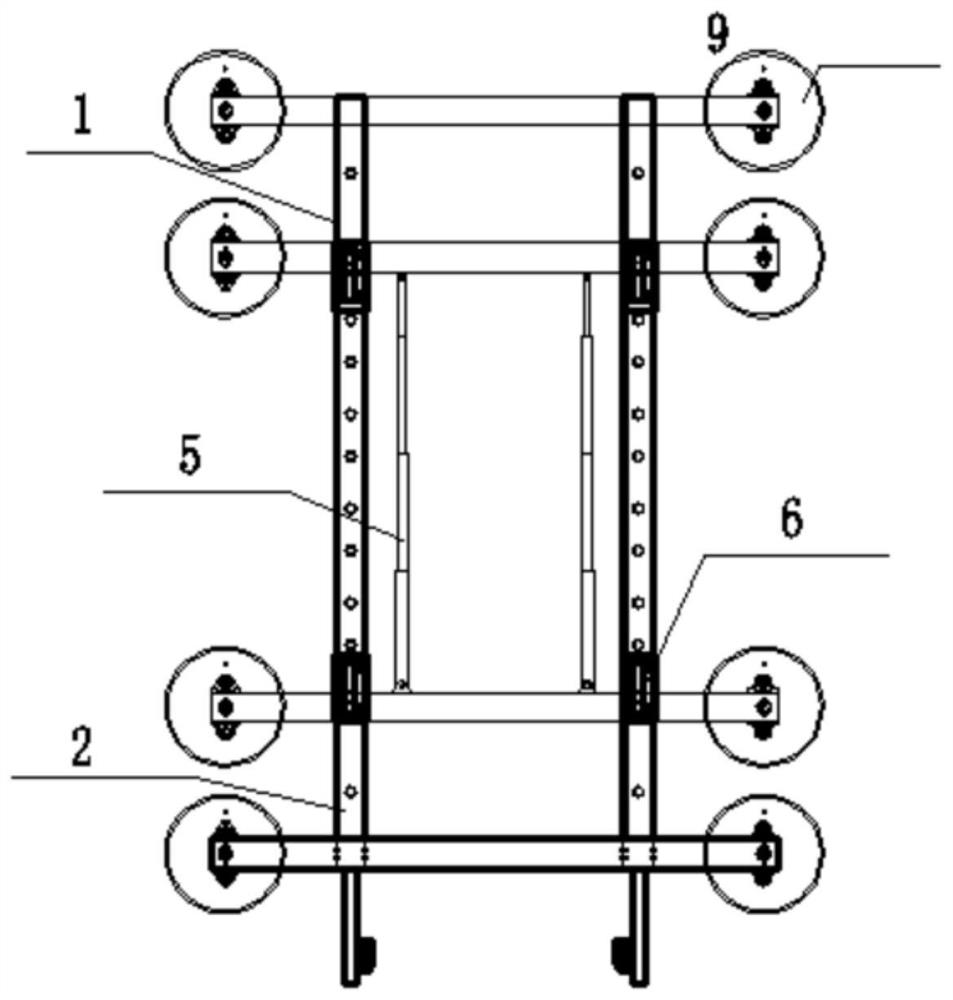

[0053] like Figure 1-8 As shown, the present invention provides an automatic crawling spraying machine, comprising: a climbing system, an adsorption system and a spraying system; the adsorption system and the spraying system are all arranged on the climbing system;

[0054] The climbing system is composed of an upper climbing frame 1, a lower climbing frame 2 and a pushing assembly. The pushing assembly connects the upper climbing frame 1 and the lower climbing frame 2, and can push the upper climbing frame 1 and the lower climbing frame. Rack 2.

[0055] In the present invention, the upper climbing frame 1 and the lower climbing frame 2 are connected by cross beams 3 and longitudinal track beams 4 to form a frame structure;

[0056] The push assembly is composed of a push rod 5 and a limit slider 6; the push rod 5 is arranged between the lower beam 3 of the climbing frame 1 and the upper beam 3 of the climbing frame 2, combined with the adsorption system, To control the re...

Embodiment 2

[0077] The method for automatic crawling spraying machine spraying comprises the following steps:

[0078] Step 1. Preparatory work (positioning and setting out, base surface cleaning, raw material mixing, suspension point installation, etc.);

[0079] Step 2. Fix the pipelines of electricity, gas and materials on the suspension rope 21 at the suspension point, move the automatic crawling spraying machine in the initial state to a predetermined position, and make the adsorption system of the climbing frame 1 close to the wall, The adsorption system of the climbing frame 2 is in a relaxed state; open the telescopic rod 7 of the adsorption system of the climbing frame 1, press the vacuum suction cup 9 against the wall, and then open the exhaust valve to vacuum the suction cup of the climbing frame 1, so that the automatic The crawling spraying machine is attached to the wall;

[0080] Step 2. Control the push rod 5 to push up the lower climbing frame 2, and at the same time ope...

Embodiment 3

[0086] On the basis of Embodiment 2, when performing step five, when a foreign object appears on the wall during the upward movement of the climbing frame 1, the radar range finder 16 measures the distance to the monitoring board 15 and sends it to the controller, and the controller Turn on the sandblasting gun 19 and the vacuum cleaner simultaneously according to the set interval time t and run for the set time T.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com