Intermediate-frequency transformer applied to power electronic transformer

A technology for power electronics and transformers, applied in the field of intermediate frequency transformers, can solve problems such as endangering personnel and equipment safety, insulating medium damage, system thermal damage, etc., and achieve the effects of improving safety, increasing withstand voltage level, and reducing temperature rise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026]In order to make the objectives, technical solutions and advantages of the present invention, the present invention will be described in further detail below with reference to the accompanying drawings and examples. It will be appreciated that the specific embodiments described herein are intended to explain the present invention and is not limited thereto.

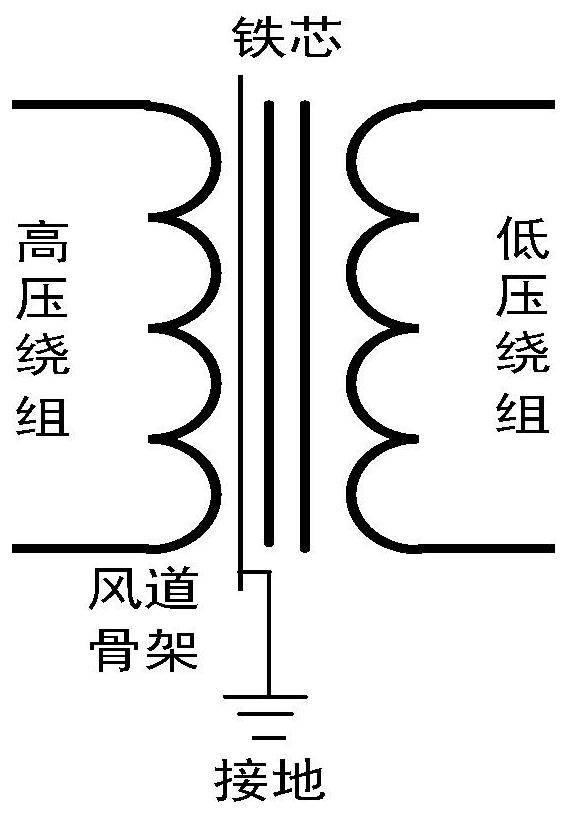

[0027]An intermediate frequency transformer applied to a power electron transformer, including a pour body, a low-voltage winding, a core assembly, and a connection assembly, and the connecting assembly secures the pour body, the low pressure winding, and the iron core assembly by screw fasteners to form an intermediate frequency transformer. Such asfigure 1 As shown, the wind bone frame is formed to form an equal potential body, which can effectively suppress the local discharge of the intermediate frequency transformer.

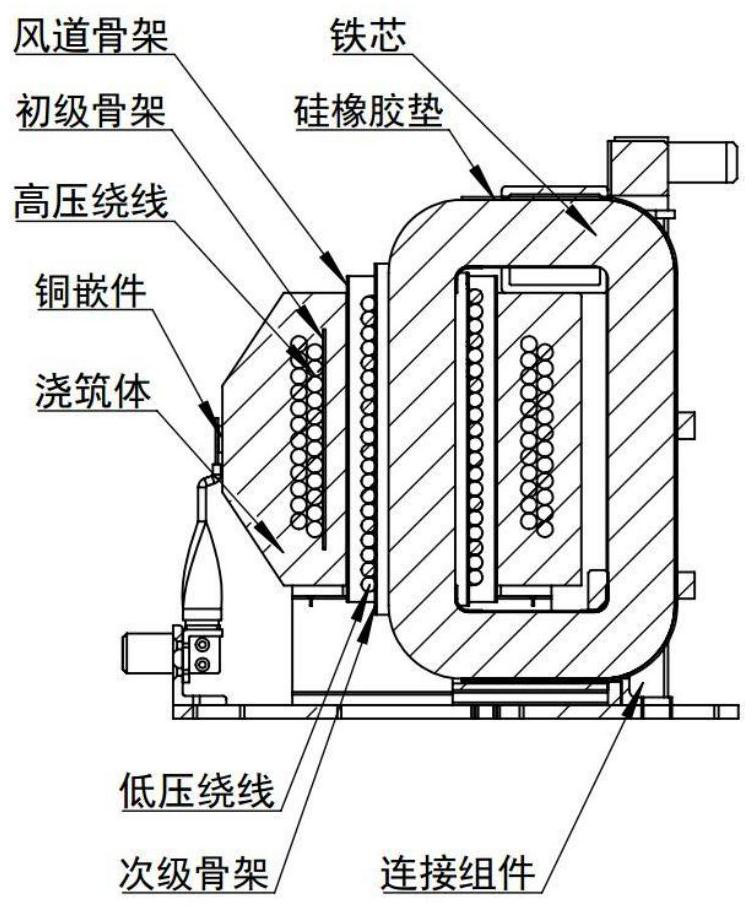

[0028]Such asfigure 2 As shown, an intermediate frequency transformer applied to a power electron transfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com