Coated microcrystalline glass with improved hydrophobicity and lipophobicity as well as preparation method and application thereof

A technology of glass-ceramic and oil layer, applied in the direction of coating etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

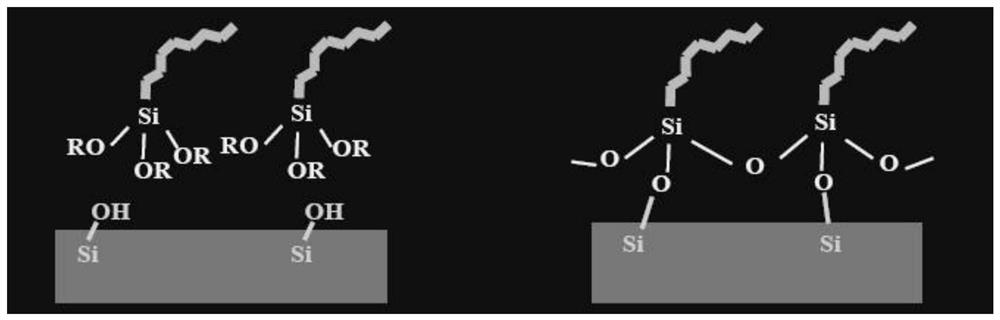

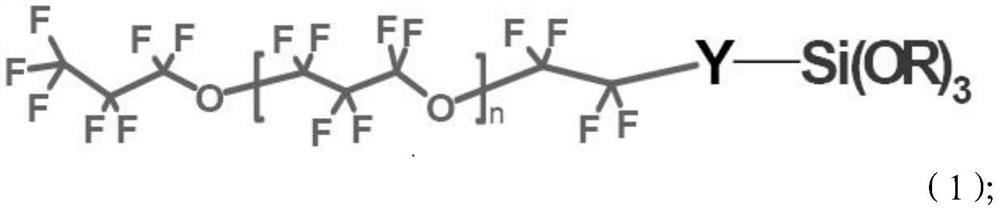

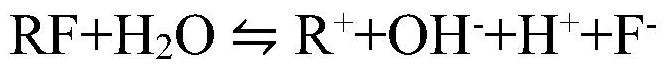

Method used

Image

Examples

Embodiment 2~15

[0174] The steps of the preparation method are the same as those in Example 1, and the differences are shown in Table 1, Table 2 and Table 3. That is to say, the specific composition of each raw material of the glass frit, the heat treatment process conditions of step (2) and the properties of the obtained glass-ceramic The test and step (3) ion exchange process conditions and the performance test results of the obtained strengthened glass-ceramic are shown in Table 1, Table 2 and Table 3 for details.

[0175] Table 1 Raw materials for preparing glass (mol%)

[0176]

[0177] Table 2 Processing conditions of plain glass (unstrengthened glass ceramics) and performance parameters of glass ceramics after heat treatment

[0178]

[0179]

[0180] It can be seen from the above table 2 that the glass ceramic obtained by the plain glass obtained by the present invention after heat treatment has the lowest crystallinity of 61.2% and the highest of 90.35%, the visible light tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com