Preparation method of formamidinium bromide perovskite quantum dots with controllable size

A technology of amidine bromide-based perovskite and quantum dots, which is applied in the field of quantum dot material preparation, can solve the problems of low preparation efficiency, long preparation time of solid-phase method, complicated operation, etc., and achieve low preparation equipment requirements, low raw material prices, The effect of the simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Measured 0.1 mmol of formamidine acetate, 0.1 mmol of lead bromide, 10 uL of hydrogen bromide, 0.1 mmol of oleic acid and 0.1 mmol of oleylamine were mixed in a test tube, and the mixture was completely dissolved in 5 ml of dimethylformamide , to prepare a perovskite precursor; inject the precursor into a vigorously stirred toluene solution to obtain a mixed solution; centrifuge the mixed solution in a centrifuge tube at 6000 rpm for 5 minutes to remove residual precursors and large products, take out the supernatant, and then Centrifuge at 12000rpm for 5min, then take out the supernatant, and disperse the precipitate in toluene to obtain FAPbBr 3 Mineral Quantum Dots.

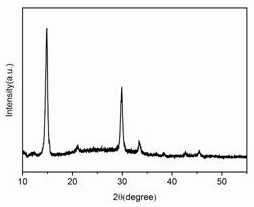

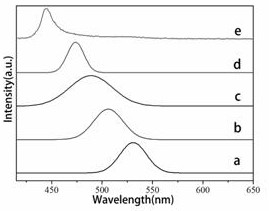

[0030] The resulting FAPbBr 3 The photo of quantum dot suspension under ultraviolet light is as follows: figure 1 As shown in the left 1, the quantum dot solution emits brighter green fluorescence, indicating that high-quality quantum dots are prepared with high quality; its XRD is as follows figure...

Embodiment 2

[0032] Measured 0.1 mmol of formamidine acetate, 0.1 mmol of lead bromide, 10 uL of hydrogen bromide, 0.1 mmol of oleic acid and 0.1 mmol of oleylamine were mixed in a test tube, and the mixture was completely dissolved in 5 ml of dimethylformamide , to prepare a perovskite precursor; mix the precursor with an additional 3 uL hydrogen bromide additive in a beaker, and inject them into a vigorously stirred toluene solution to obtain a mixed solution; centrifuge the mixed solution in a centrifuge tube at 6000rpm for 5min , remove residual precursors and large products, take out the supernatant, and then centrifuge at 12000rpm for 5min, then take out the supernatant, and disperse the precipitate in toluene to obtain formamidine bromide perovskite quantum dots.

[0033] The resulting FAPbBr 3 The photo of the quantum dot suspension under the irradiation of ultraviolet light is as follows: figure 1 As shown in the second from the left, the solution emits brighter fluorescence, and...

Embodiment 3

[0035] Measured 0.1 mmol of formamidine acetate, 0.1 mmol of lead bromide, 10 uL of hydrogen bromide, 0.1 mmol of oleic acid and 0.1 mmol of oleylamine were mixed in a test tube, and the mixture was completely dissolved in 5 ml of dimethylformamide , to prepare a perovskite precursor; put the precursor and 6 uL of hydrogen bromide additive in a beaker and mix them, and inject them into the vigorously stirred toluene solution to obtain a mixed solution; centrifuge the mixed solution in a centrifuge tube at 6000rpm for 5min, Remove residual precursors and large products, take out the supernatant, and then centrifuge at 12,000 rpm for 5 minutes, then take out the supernatant, and disperse the precipitate in toluene to obtain formamidine bromide perovskite quantum dots with controllable size.

[0036] The resulting FAPbBr 3 The photo of the quantum dot suspension under the irradiation of ultraviolet light is as follows: figure 1 As shown in the third from the left, the quantum do...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com