Multifunctional hardening film and method thereof

A hardened film, multi-functional technology, applied in paints containing biocides, conductive coatings, polyether coatings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

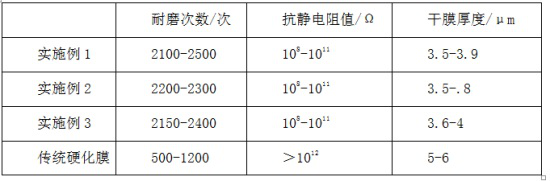

Embodiment 1

[0023] A multifunctional hardening film, comprising an acrylic resin hardening solution in which a transparent polyimide substrate is mixed with an ionic antistatic agent, and the preparation method specifically includes the following steps:

[0024] S1: Apply the hardening solution evenly on the transparent polyimide substrate through the dimple coating process;

[0025] S2: The transparent polyimide substrate coated with the hardening solution is cured by UV-A band ultraviolet light, and it is protected by nitrogen gas during curing, and the cured thickness is 3.5 μm;

[0026] S3: Transport the cured cured film to an oven for drying, and then perform annealing treatment. After the cured film is cooled, attach the protective film and cut it.

[0027] Specifically, the dimple coating process in this embodiment specifically uses a 120-line, 45° oblique-type dimple coating roll, and the coating solid content of the dimple coating roll is 500mJ / cm 2 , The coating speed ratio is ...

Embodiment 2

[0033] A multifunctional hardening film, comprising an acrylic resin hardening solution in which a transparent polyimide substrate is mixed with an ionic antistatic agent, and the preparation method specifically includes the following steps:

[0034] S1: Apply the hardening solution evenly on the transparent polyimide substrate through the dimple coating process;

[0035] S2: The transparent polyimide substrate coated with the hardening solution is cured by UV-A band ultraviolet light, and it is protected by nitrogen gas during curing, and the cured thickness is 3 μm;

[0036] S3: Transport the cured cured film to an oven for drying, and then perform annealing treatment. After the cured film is cooled, attach the protective film and cut it.

[0037] Specifically, the dimple coating process in this embodiment specifically uses a 120-line, 45° oblique-type dimple coating roller, and the coating solid content of the dimple coating roller is 550mJ / cm 2 , The coating speed ratio i...

Embodiment 3

[0043] A multifunctional hardening film, comprising an acrylic resin hardening solution in which a transparent polyimide substrate is mixed with an ionic antistatic agent, and the preparation method specifically includes the following steps:

[0044] S1: Apply the hardening solution evenly on the transparent polyimide substrate through the dimple coating process;

[0045] S2: The transparent polyimide substrate coated with the hardening solution is cured by UV-A band ultraviolet light, and the curing is protected by nitrogen gas, and the curing thickness is 4m;

[0046] S3: Transport the cured cured film to an oven for drying, and then perform annealing treatment. After the cured film is cooled, attach the protective film and cut it.

[0047] Specifically, the dimple coating process in this embodiment specifically uses a 120-line, 45° oblique-type dimple coating roller, and the coating solid content of the dimple coating roller is 600mJ / cm 2 , The coating speed ratio is 20m / m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com