A connection structure between corner frame and railing frame

A connection structure and outer frame technology, applied in the field of doors and windows, can solve the problems of high manufacturing cost of the corner part, complex corner frame structure, and difficult installation of doors and windows, etc., and can easily guarantee the waterproof treatment effect, improve the waterproof treatment effect, and save the installation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

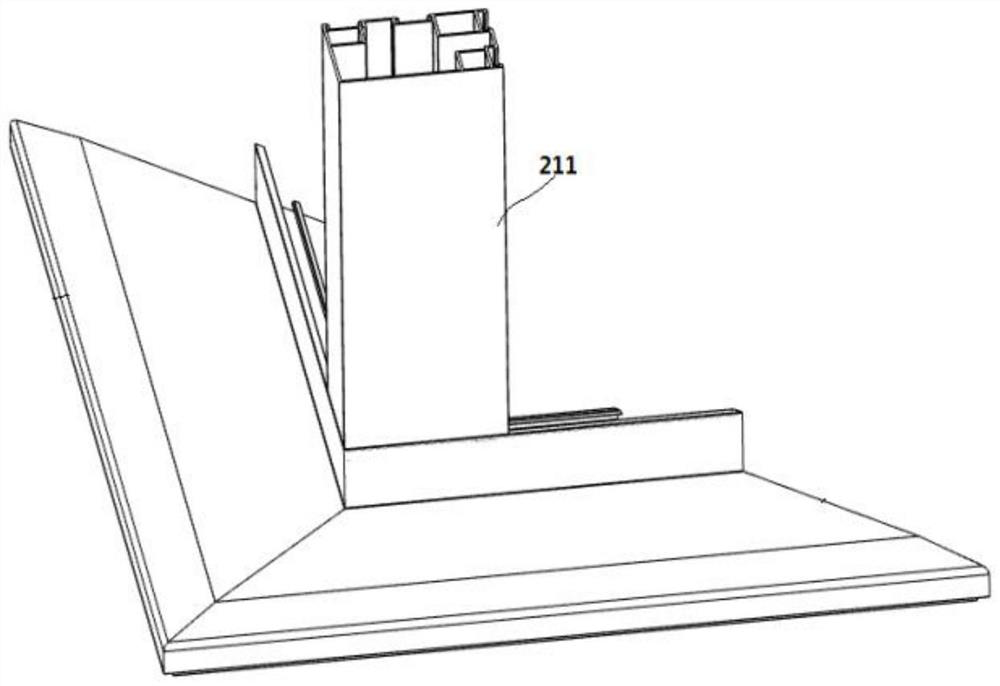

[0047] see Figure 1-8 , an embodiment provided by the present invention: a connection structure between a corner frame 211 and a railing frame, including a corner frame 211 and a corner frame assembly at a 90° corner, wherein the corner frame 211 is connected to the corner by a vertical corner code The outer frame components are fixedly connected;

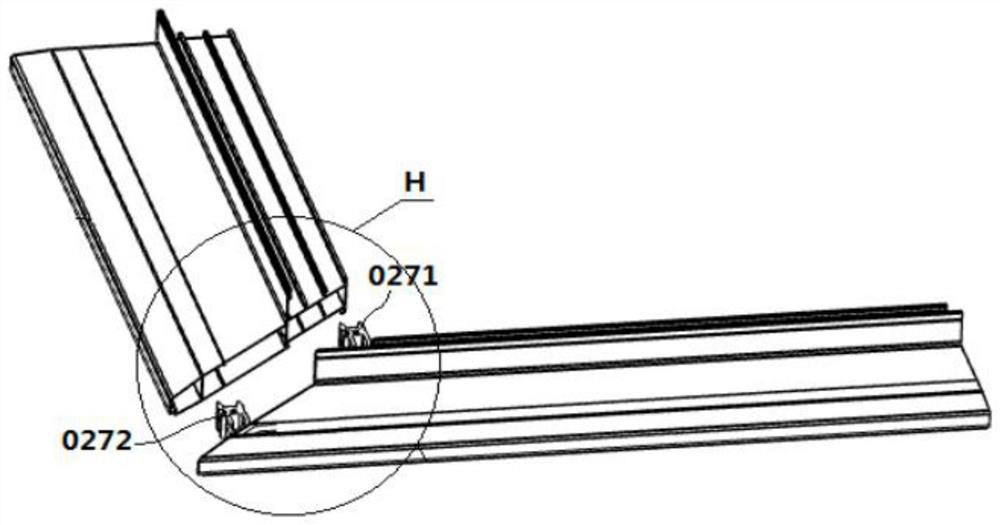

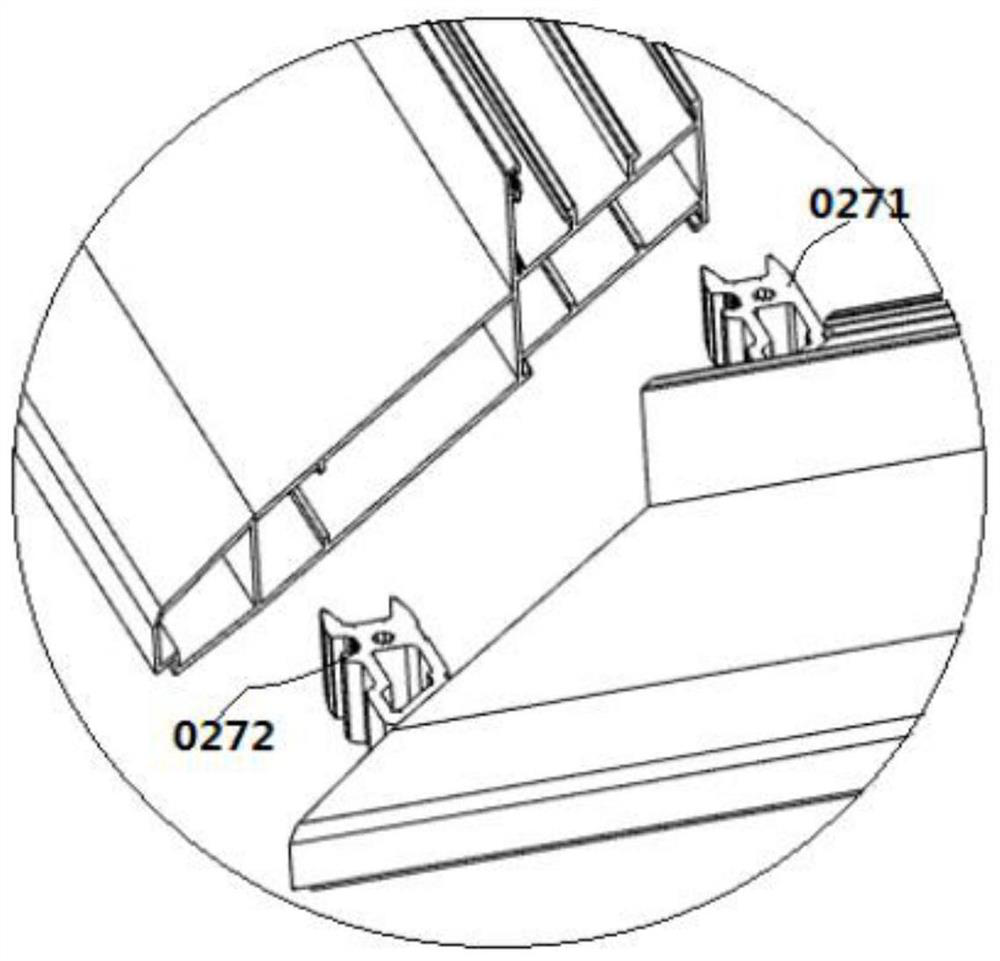

[0048] For details, please refer to Figure 1-3 , the corner outer frame assembly includes a railing outer frame with a cut angle of 45° connected on the same plane through the first transverse corner code 0271 and the second transverse corner code 0272. Through the above structure, the present invention cuts the two railing outer frames when the group is assembled. 45°normal group angle, the processing precision of this corner cutting process is high, and then the waterproof treatment here can be realized through appropriate glue, and the waterproof treatment effect is easy to guarantee. When connecting, glue can be injected in...

Embodiment 2

[0052] The difference between the second embodiment and the first embodiment is that

[0053] For details, please refer to Figure 9 , 10 , 11, 12 and 13, the outer corner of the corner frame 211 is slid to be provided with reinforcing assembly along its length direction, and the reinforcing assembly is the hollow bar-shaped body 1 that section is right-angle fan-shaped, and wherein, the arc surface of hollow bar-shaped body 1 and right angle An outwardly protruding limit bar 11 is provided at the surface joint, and the corner frame 211 on one side of the limit bar 11 is provided with a limit groove 12 that matches the limit bar 11, and two limit baffles are provided at the corner positions There is a corner connection assembly, and the corner connection assembly includes a top plate 3 that fits with the upper end faces of the two limit baffles at the corner positions, and is vertically arranged at the bottom of the top plate 3 and fits with the third limit rib 2616 of the tw...

Embodiment 3

[0056] see Figure 14-19 , an embodiment provided by the present invention: a connection structure between a corner frame 211 and a railing frame, including a corner frame 211 and a corner frame assembly at a 90° corner, wherein the corner frame 211 is connected to the corner by a vertical corner code The outer frame components are fixedly connected;

[0057] For details, please refer to Figure 1-3 , the corner outer frame assembly includes a railing outer frame with a cut angle of 45° connected on the same plane through the first transverse corner code 0271 and the second transverse corner code 0272. Through the above structure, the present invention cuts the two railing outer frames when the group is assembled. 45°normal group angle, the processing precision of this corner cutting process is high, and then the waterproof treatment here can be realized through appropriate glue, and the waterproof treatment effect is easy to guarantee. When connecting, glue can be injected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com