Lithium battery diaphragm with overcharge protection function, and preparation method thereof

A lithium battery diaphragm and overcharge protection technology, which is applied to battery components, circuits, electrical components, etc., can solve the problems of battery safety, increase battery complexity and production costs, and prevent overcharge , Prevent the continuous rise of voltage and improve the effect of thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

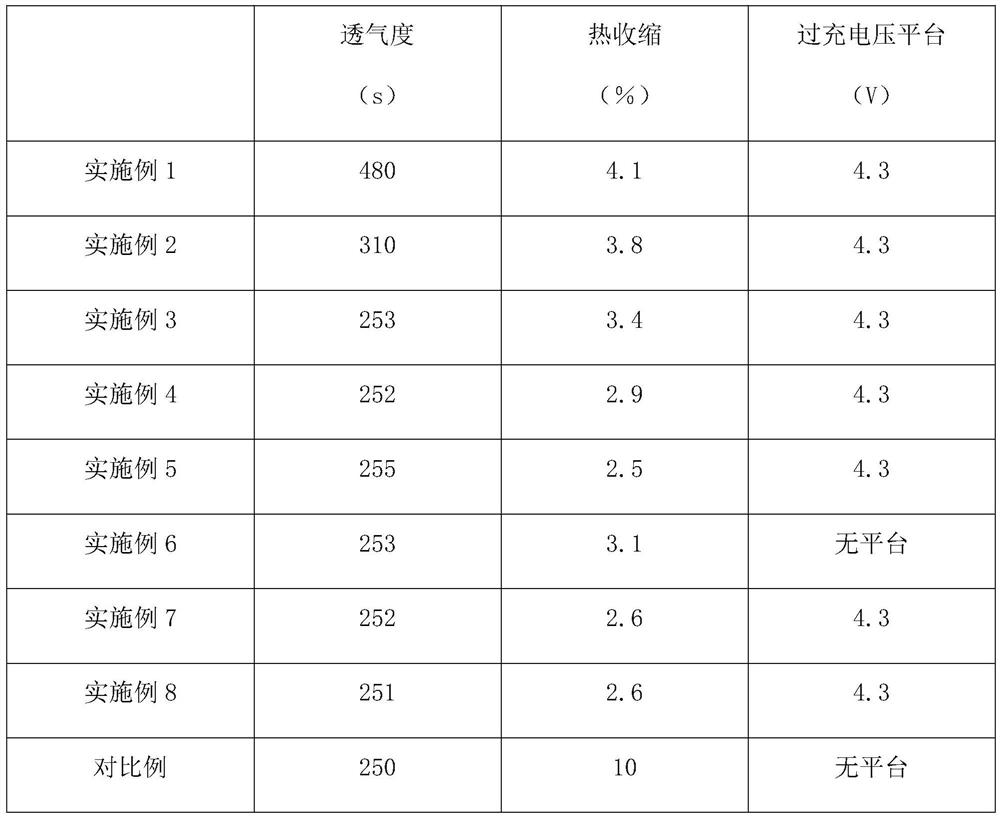

Examples

Embodiment 1

[0028] (1) Prepare materials: weigh 10g of poly(p-phenylene vinylene derivative), 48g of polyacrylic acid, 2g of crosslinking agent, and 40g of polyvinyl alcohol for subsequent use;

[0029] (2) Preparation of slurry: dissolve the above materials into dichloromethane, set the dissolution temperature to 5°C, and the stirring speed during dissolution is 250rpm, and prepare a slurry with a viscosity of 300mPa·s;

[0030] (3) Dip coating: the substrate is immersed in the coating tank, the angle of immersion and extraction is 45°, the immersion speed is set to be 30cm / min, and the transfer roller is extracted to form coating A and obtain diaphragm B;

[0031] (4) Cross-linking: Send the diaphragm B into the hot air channel, dichloromethane volatilizes into the recovery system, and the coating forms a cross-linking structure under the action of the cross-linking agent. Set the cross-linking temperature to 90°C and the cross-linking time to 25 minutes , to obtain diaphragm C;

[003...

Embodiment 2

[0034] (1) Prepare materials: weigh 10g of poly(p-phenylene vinylene derivative), 43g of polyacrylic acid, 2g of crosslinking agent, and 45g of polyvinyl alcohol for subsequent use;

[0035] (2) Preparation of slurry: dissolve the above materials into dichloromethane, set the dissolution temperature to 5°C, and the stirring speed during dissolution is 250rpm, and prepare a slurry with a viscosity of 300mPa·s;

[0036] (3) Dip coating: the substrate is immersed in the coating tank, the angle of immersion and extraction is 45°, the immersion speed is set to be 30cm / min, and the transfer roller is extracted to form coating A and obtain diaphragm B;

[0037] (4) Cross-linking: Send the diaphragm B into the hot air channel, dichloromethane volatilizes into the recovery system, and the coating forms a cross-linking structure under the action of the cross-linking agent. Set the cross-linking temperature to 90°C and the cross-linking time to 25 minutes , to obtain diaphragm C;

[003...

Embodiment 3

[0040] (1) Prepare materials: weigh 10 g of poly(p-phenylene) derivatives, 38 g of polyacrylic acid, 2 g of crosslinking agent, and 50 g of polyvinyl alcohol for subsequent use;

[0041] (2) Preparation of slurry: dissolve the above materials into dichloromethane, set the dissolution temperature to 5°C, and the stirring speed during dissolution is 250rpm, and prepare a slurry with a viscosity of 300mPa·s;

[0042] (3) Dip coating: the substrate is immersed in the coating tank, the angle of immersion and extraction is 45°, the immersion speed is set to be 30cm / min, and the transfer roller is extracted to form coating A and obtain diaphragm B;

[0043] (4) Cross-linking: Send the diaphragm B into the hot air channel, dichloromethane volatilizes into the recovery system, and the coating forms a cross-linking structure under the action of the cross-linking agent. Set the cross-linking temperature to 90°C and the cross-linking time to 25 minutes , to obtain diaphragm C;

[0044] (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com