Preparation method of zein-gallic acid composite colloidal particles and emulsion thereof

A technology of zein and gallic acid, applied in food ingredients as emulsifiers, food science, food ingredients, etc., can solve the problems of environmental sensitivity and poor stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

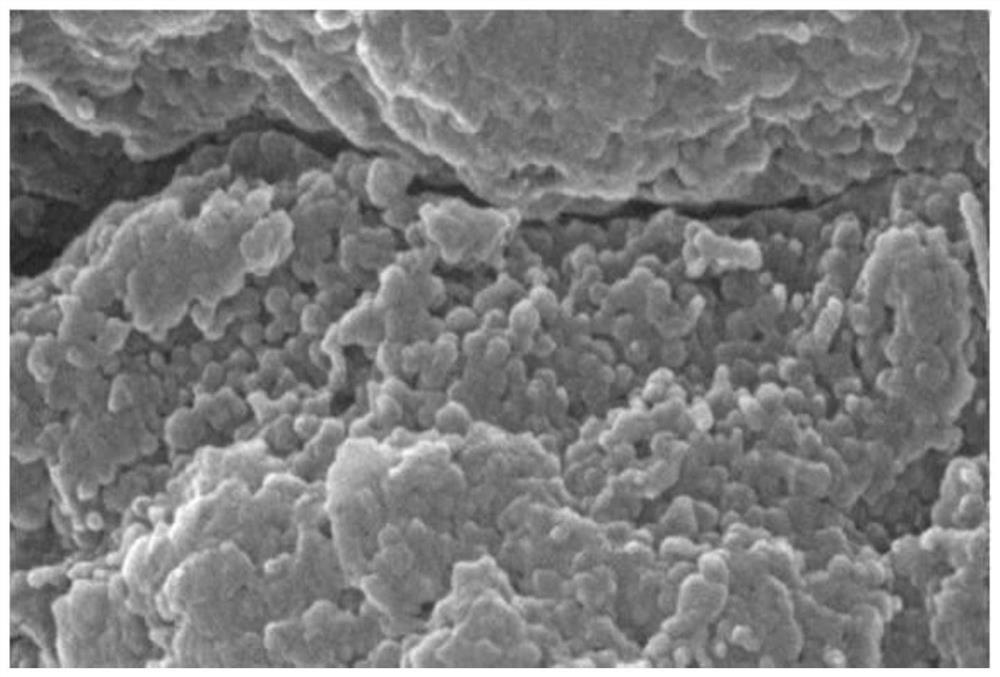

[0036] A preparation method of zein-gallic acid composite colloidal particles and emulsion thereof, comprising the steps of:

[0037] S1. Weigh 2 g of zein powder and dissolve it in 100 ml of 70% ethanol solution, place it in a stirring device, stir at 800 rpm for 2 hours, prepare a 2% zein solution, and store it in a refrigerator at 5°C overnight;

[0038] S2. Take the zein solution prepared in step S1, add 0.2 g of gallic acid powder at a rotating speed of 850 rpm, and continue stirring until the gallic acid is completely dissolved, that is, the zein-gallic acid stock solution;

[0039] S3. Rotate and stir the zein-gallic acid stock solution prepared in step S2 under the condition of 1000 rpm, pour it into distilled water 2.4 times its volume in a thin stream, stir for 15 minutes and remove the ethanol in the solution by rotary evaporation, namely Obtain zein-gallic acid composite colloid particle solution;

[0040] S4. Pour the composite colloid particle solution prepared...

Embodiment 2

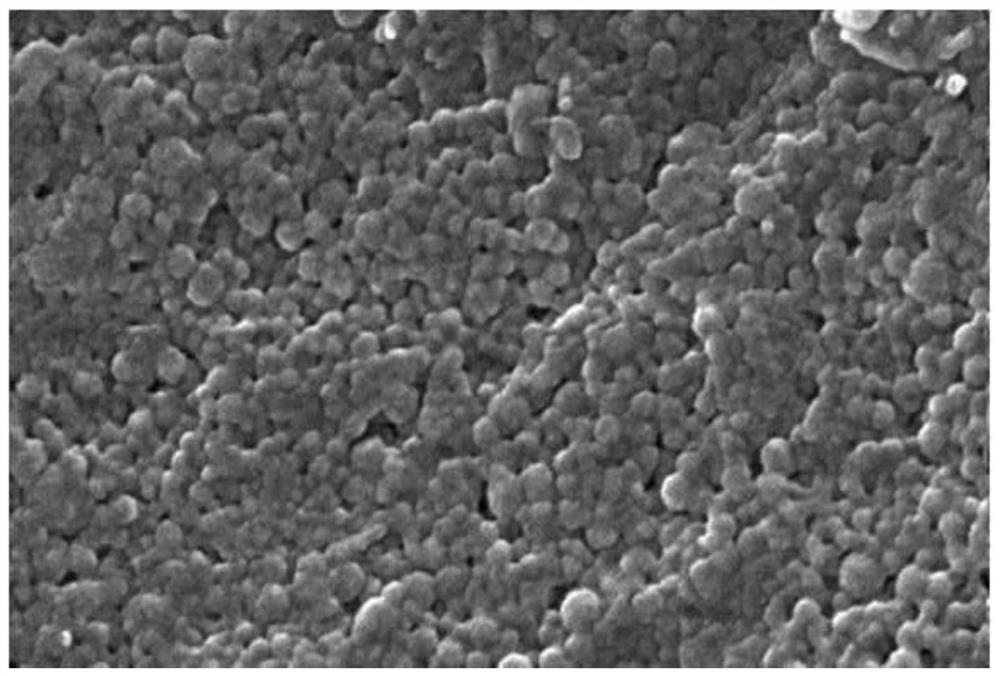

[0044] A preparation method of zein-gallic acid composite colloidal particles and emulsion thereof, comprising the steps of:

[0045] S1. Weigh 1.5g of zein powder and dissolve it in 100ml of 70% ethanol solution, place it in a stirring device, stir at 850rpm for 2.5h, prepare a 2% zein solution, and place it in a refrigerator at 3°C stored overnight;

[0046] S2. Take the zein solution prepared in step S1, add 0.4 g of gallic acid powder at a rotating speed of 800 rpm, and continue stirring until the gallic acid is completely dissolved, that is, the zein-gallic acid stock solution;

[0047]S3. Rotate and stir the zein-gallic acid stock solution prepared in step S2 under the condition of 1100 rpm, pour it into distilled water 2.5 times its volume in a thin stream, stir for 14 minutes and remove the ethanol in the solution by rotary evaporation, that is Obtain zein-gallic acid composite colloid particle solution;

[0048] S4. Pour the composite colloidal particle solution pre...

Embodiment 3

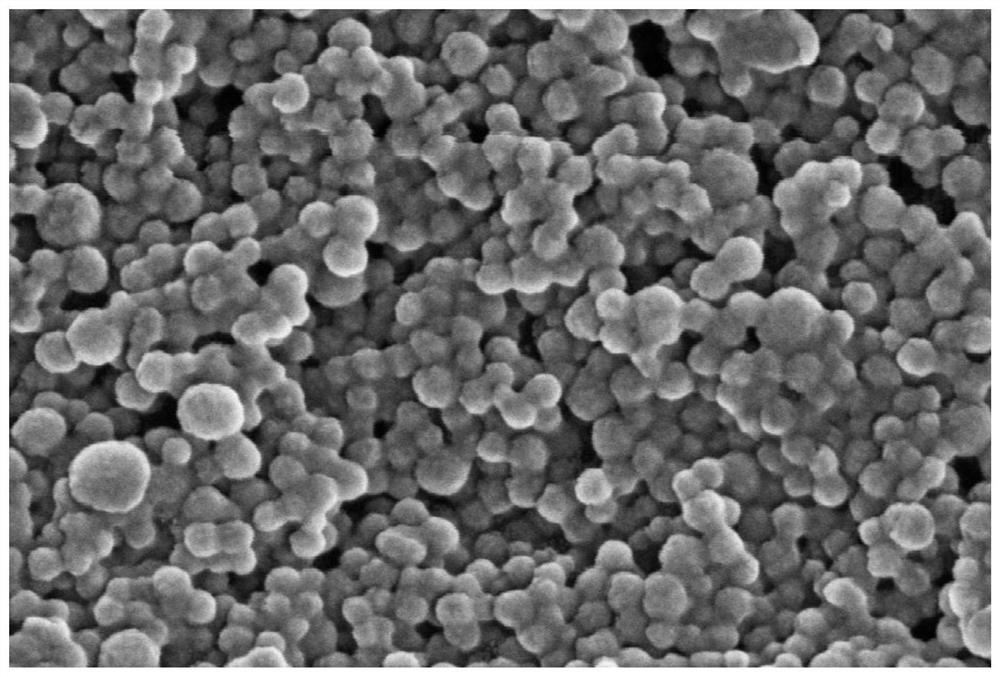

[0052] A preparation method of zein-gallic acid composite colloidal particles and emulsion thereof, comprising the steps of:

[0053] S1. Weigh 2 g of zein powder and dissolve it in 100 ml of 70% ethanol solution, place it in a stirring device, stir at 860 rpm for 2 hours, prepare a 2% zein solution, and store it in a refrigerator at 4°C overnight;

[0054] S2. Take the zein solution prepared in step S1, add 0.6 g of gallic acid powder at a rotating speed of 900 rpm, and continue stirring until the gallic acid is completely dissolved, that is, the zein-gallic acid stock solution;

[0055] S3. Rotate and stir the zein-gallic acid stock solution prepared in step S2 at 1200rpm, pour it into distilled water twice its volume in a thin stream, stir for 12min and remove the ethanol in the solution by rotary evaporation, that is Obtain zein-gallic acid composite colloid particle solution;

[0056] S4. Pour the composite colloid particle solution prepared in S3 into a plate, use a va...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com