Negative-pressure vacuum packaging machine for packaging high-quality white carbon black

A technology of vacuum packaging machine and silica, which is applied in the direction of packaging, transportation and packaging, and the type of packaged items. It can solve the problems of reducing the one-time loading capacity of packaging bags and the inability to effectively discharge silica gas, so as to increase one-time loading. Quantity, simple structure, and the effect of reducing gas content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

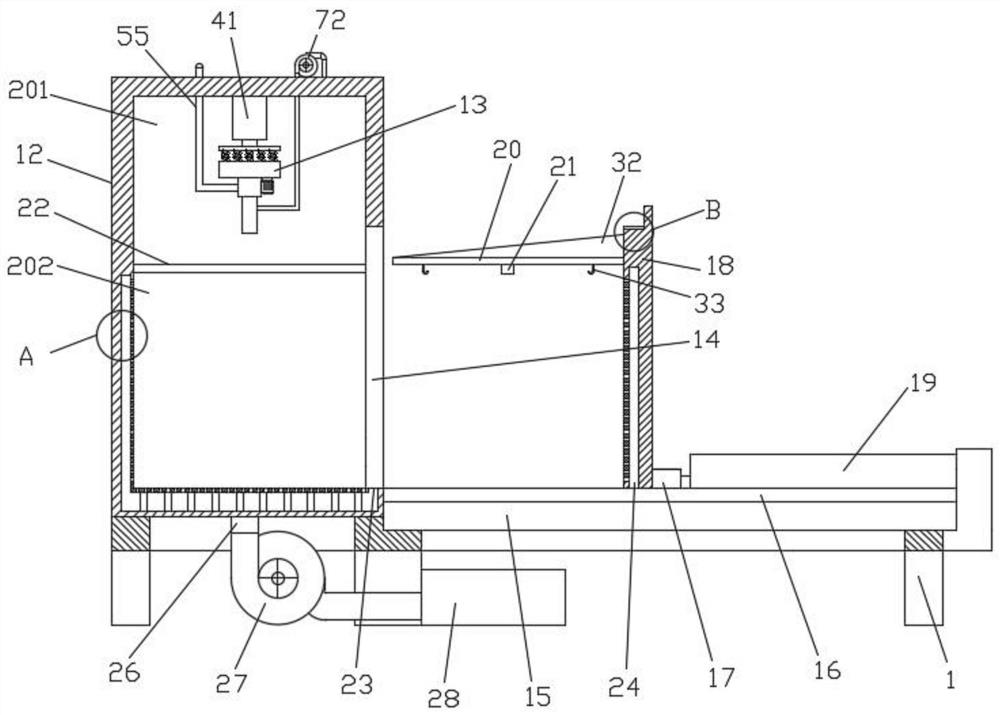

[0025] Such as Figure 1-3 Shown; a negative pressure vacuum packaging machine for high-quality white carbon black packaging, including:

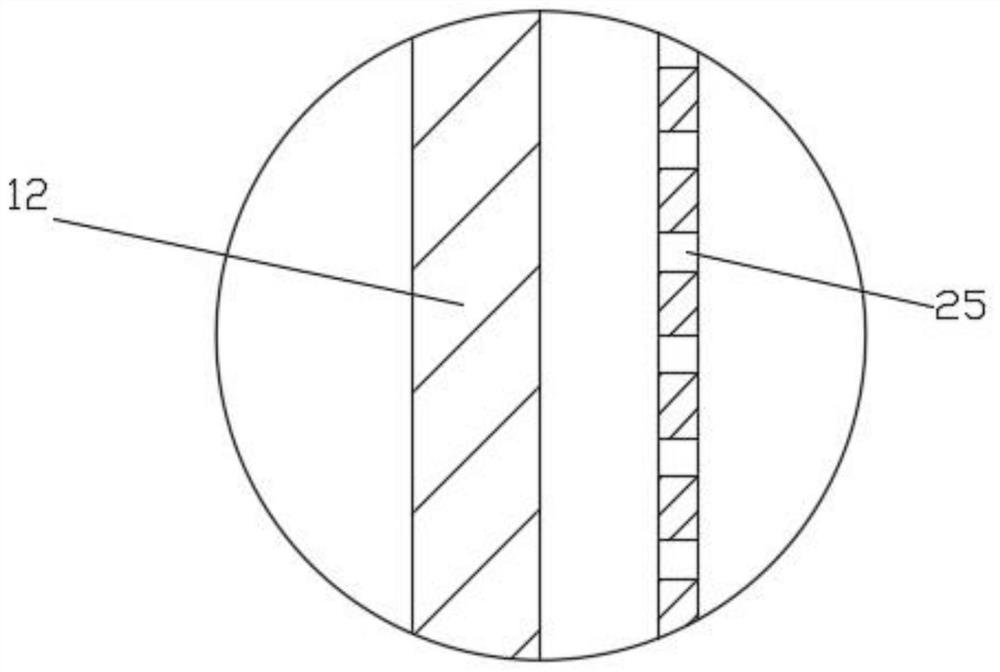

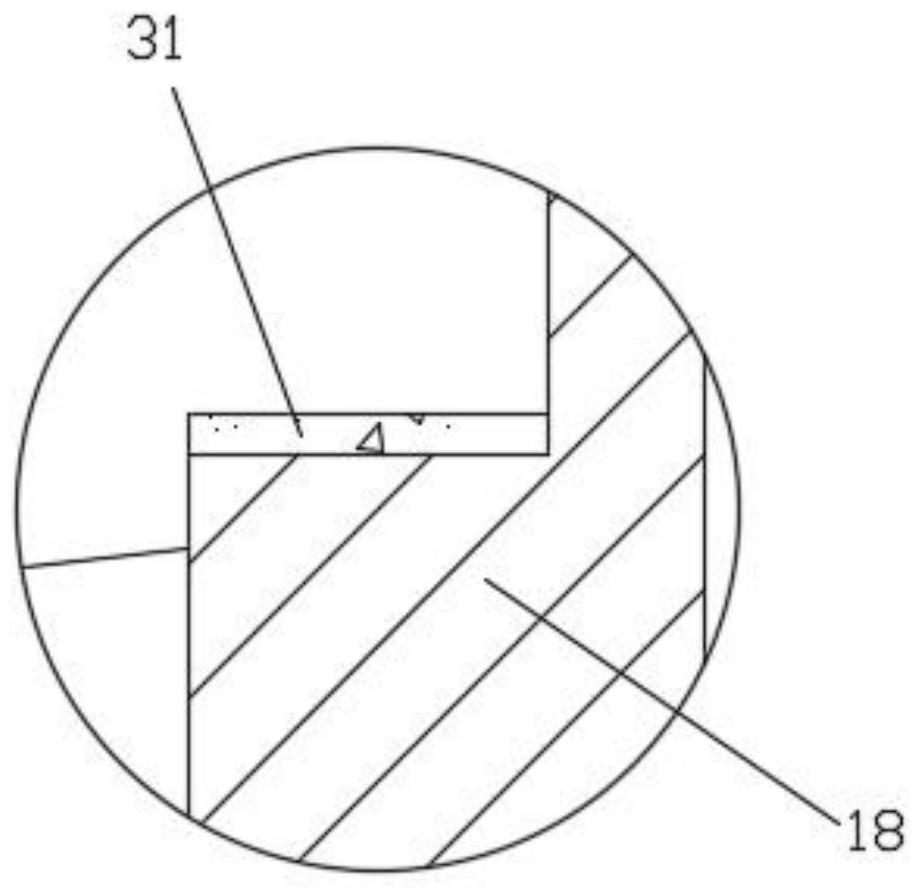

[0026] Device bracket 1, a sealing box 12 is installed on the device bracket 1, a material injection nozzle 13 is installed on the top of the sealing box 12, a feeding port 14 is provided on one side of the sealing box 12, and a feeding port 14 is installed on the device bracket 1 at the feeding port 14. Material conveying roller frame 15, discharge guide rail 16 is installed on the feed conveying roller frame 15, on the discharge guide rail 16, movable block 17 is slidably installed, hatch door 18 is installed on the movable block 17, and the discharge guide rail 16 is far away from the feed port A feeding push rod 19 is installed between one end of 14 and the hatch door 18, a support plate 20 is fixed on the hatch door 18, and a feed port 21 is provided on the support plate 20;

[0027] The inside of the sealing box 12 is provided with a...

Embodiment 2

[0033] On the basis of Example 1, such as figure 1 , image 3 As shown; the existing injection nozzle 13 is easy to cause the internal blockage of the nozzle during the injection process. In order to prevent the above problems, a telescopic push rod 41 is installed inside the injection bin 201, and the output end of the telescopic push rod 41 is installed with an intermediate The plate 42, the lower part of the middle plate 42 is fixed with a support spring 43, the injection nozzle 13 is installed on the support spring 43, and the injection nozzle 13 includes a housing 51 and a feeding rod 52;

[0034] The upper part of the housing 51 is equipped with a driving box 53, and the lower part of the housing 51 is equipped with an injection pipe 54. The injection pipe 54 communicates with the housing 51, and the side of the housing 51 is connected with a material pipe 55; the feeding rod 52 is arranged on the injection pipe. 54 inside, the feeding rod 52 passes through the drive bo...

Embodiment 3

[0038] On the basis of Example 2, such as Figure 1-5 Shown; After the material injection nozzle 13 completes the material injection, its end is extracted from the packaging bag, and part of the powder will be brought out at the end, which will easily cause dust and waste of the powder. The limit sleeve 71, the diameter of the injection pipe 54 is larger than the diameter of the limit sleeve 71, the side wall of the injection pipe 54 is a hollow structure, and the hollow structure in the side wall of the injection pipe 54 is connected to the air inlet of the auxiliary fan 72 through a pipeline , the air outlet of the auxiliary fan 72 is connected to the bag filter 28, and the lower end of the injection pipe 54 is provided with a suction hole 73.

[0039] There is a sealing ring 74 on the side ring of the outer ring of the limit sleeve 71 , and the outer diameter of the sealing ring 74 is equal to the inner diameter of the injection pipe 54 .

[0040] When injecting material, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com