Material for surgical instruments and preparation method of steel strip of material

A technology for surgical instruments and steel strips, which is applied in the field of preparation of materials for surgical instruments and their steel strips, can solve the problems of toughness and corrosion resistance that cannot be used for a long time, so as to improve toughness and corrosion resistance, and refine grains Organize and ensure the effect of surgical safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

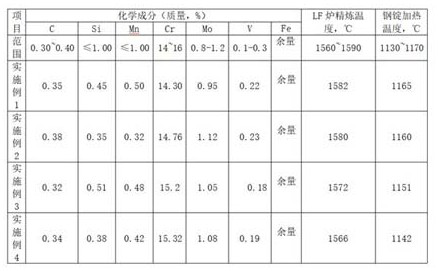

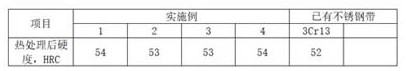

Embodiment 1

[0027]A surgical instrument material comprising the chemical component of the material: 0.35%, Si: 0.45%, Mn: 0.5%, Cr: 14.3%, the remaining is Mo, V and Fe, where the material is Mo, V and Fe The chemical composition of the inner MO and V is MO: 0.95% and V: 0.22% by weight, including the upper limit of the upper limit of 30Cr13 standard 0.26-0.35%, ensured that the hardness and sharpness of the heat treatment, including Cr From 13%, improved corrosion resistance and wear resistance, add MO and V to improve the corrosion resistance, refine the grain tissue, and improve heat treatment hardenability, and improve the mechanical properties of materials.

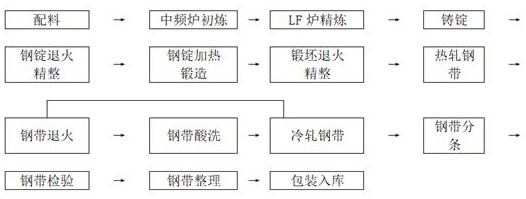

[0028]A method for preparing a steel strip made of a surgical instrument according to claim 1, wherein the specific steps include:

[0029]1) Press by weight: Stainless steel scrap, carbon scrap steel and iron alloy priming in medium frequency furnaces, until the weight percentage of chemical components meets the requirements;

[0030]2) Water...

Embodiment 2

[0035]A surgical instrument material, including the chemical composition of the material: 0.38%, Si: 0.35%, Mn: 0.32%, Cr: 14.76%, the remainder of Mo, V and Fe, which is Mo, V and Fe, which The chemical composition of Mo and V is MO: 1.12% and V: 0.23% by weight, including the upper limit of the upper limit of the 30Cr13 standard 0.26-0.35%, ensured that the hardness and sharpness of the heat treatment, including Cr From 13%, improved corrosion resistance and wear resistance, add MO and V to improve the corrosion resistance, refine the grain tissue, and improve heat treatment hardenability, and improve the mechanical properties of materials.

[0036]A method for preparing a steel strip made of a surgical instrument according to claim 1, wherein the specific steps include:

[0037]1) Press by weight: Stainless steel scrap, carbon scrap steel and iron alloy priming in medium frequency furnaces, until the weight percentage of chemical components meets the requirements;

[0038]2) Watering stee...

Embodiment 3

[0043]An surgical instrument material, including the chemical composition of the material: C: 0.32%, Si: 0.51%, Mn: 0.48%, Cr: 15.2%, and Fe, which is Mo, V and Fe, which is Mo, V and Fe, which The chemical composition of the inner MO and V is MO: 1.05% and V: 0.18% by weight, including the upper limit of the upper limit of the 30Cr13 standard 0.26-0.35%, ensured that the hardness and sharpness of the heat treatment, including Cr From 13%, improved corrosion resistance and wear resistance, add MO and V to improve the corrosion resistance, refine the grain tissue, and improve heat treatment hardenability, and improve the mechanical properties of materials.

[0044]A method for preparing a steel strip made of a surgical instrument according to claim 1, wherein the specific steps include:

[0045]1) Press by weight: Stainless steel scrap, carbon scrap steel and iron alloy priming in medium frequency furnaces, until the weight percentage of chemical components meets the requirements;

[0046]2) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com