Preservation method for preventing tuna white meat from being oxidized

A preservation method, tuna technology, applied in the preservation of meat/fish, chemical instruments and methods, preservation of meat/fish with chemicals, etc., can solve the problems of manpower shortage, yellowing, corruption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

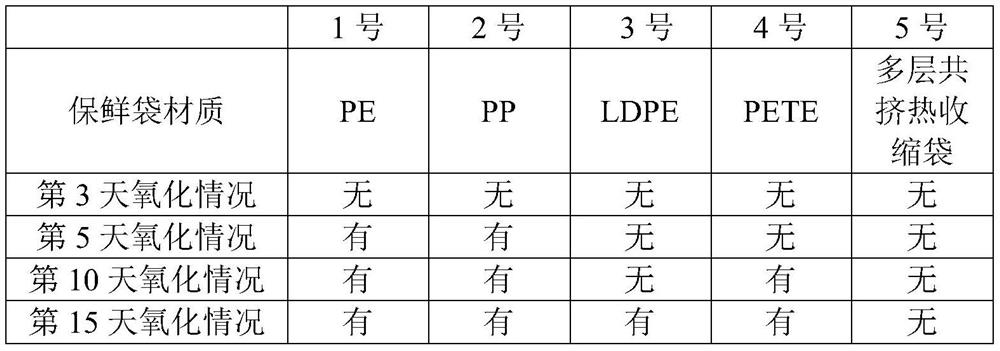

[0020] Example 1 The effect of fresh-keeping bags on the storage period of tuna white meat.

[0021] In order to verify whether different fresh-keeping bags have an impact on the storage period of tuna white meat, the following experiments were set up:

[0022] (1) Take the same piece of tuna white meat that has been steamed, peeled, boned, and red meat removed, divided into 5 pieces, and recorded as No. 1-5; put them into fresh-keeping bags of different materials.

[0023] (2) Use a vacuum machine to vacuumize the fresh-keeping bag with the tuna white meat until the vacuum degree reaches 0.9MPa and then seal it.

[0024] (3) Soak the fresh-keeping bag in step (2) in hot water at 80°C for 3 minutes to shrink it, and then put it in ice water at 0°C to cool to 10°C.

[0025] (4) Keep the temperature in the range of -16°C to -19°C, place it for a period of time, and record the oxidation of the white meat of tuna with different labels, as shown in Table 1.

[0026] Table 1

[0...

Embodiment 2

[0029] Example 2 The effect of vacuum degree on the storage period of tuna white meat.

[0030] In order to verify whether different vacuum degrees have an effect on the storage period of tuna white meat, the following experiments were set up:

[0031] (1) Take the same piece of tuna white meat that has been steamed, peeled, boned, and red meat removed, divided into 4 pieces, and recorded as No. 1-4; put them into multi-layer co-extrusion heat shrinkable bags respectively.

[0032] (2) Use a vacuum machine to evacuate the fresh-keeping bag containing the tuna white meat, and seal it after evacuating to the corresponding vacuum degree.

[0033] (3) Soak the fresh-keeping bag in step (2) in hot water at 80°C for 3 minutes to shrink it, and then put it in ice water at 0°C to cool to 10°C.

[0034] (4) Keep the temperature in the range of -16°C to -19°C, place it for a period of time, and record the oxidation conditions of the white meat of tuna with different labels, as shown in...

Embodiment 3

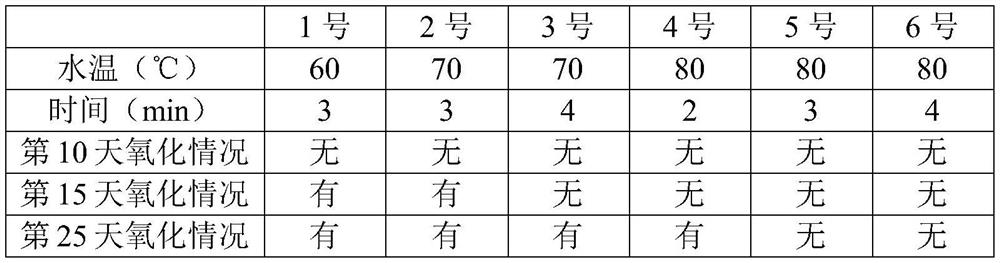

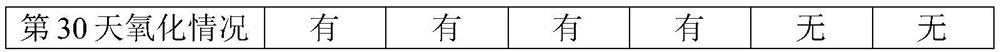

[0038] Example 3 Effect of heat shrinkage on storage period of tuna white meat.

[0039] In order to verify whether different heat shrinkage temperatures and times have an effect on the storage period of tuna white meat, the following experiments were set up:

[0040] (1) Take the same piece of tuna white meat that has been steamed, peeled, boned, and red meat removed, and divided into 6 pieces, which are recorded as No. 1-6; they are respectively packed into multi-layer co-extruded heat shrinkable bags.

[0041] (2) Use a vacuum machine to vacuumize the fresh-keeping bag with the tuna white meat until the vacuum degree reaches 0.9MPa and then seal it.

[0042] (3) Soak the fresh-keeping bags in step (2) in hot water at different temperatures for a period of time, and then put them in ice water at 0°C to cool to 10°C.

[0043] (4) Keep the temperature in the range of -16°C to -19°C, place it for a period of time, and record the oxidation conditions of the white meat of tuna w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com