Edge sweeping assembly and cleaning robot

A component and side sweeping technology, applied in the field of cleaning robots, can solve problems such as the breakage of the connecting bar 12 and the breakage of the single-tuft hair-planting brush body, and achieve the effects of high production efficiency, simple structure and high cleaning efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

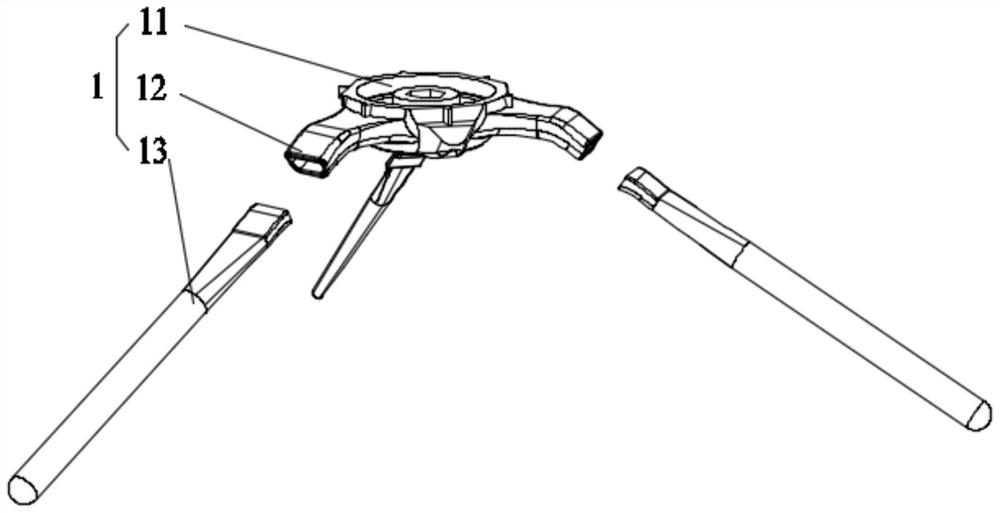

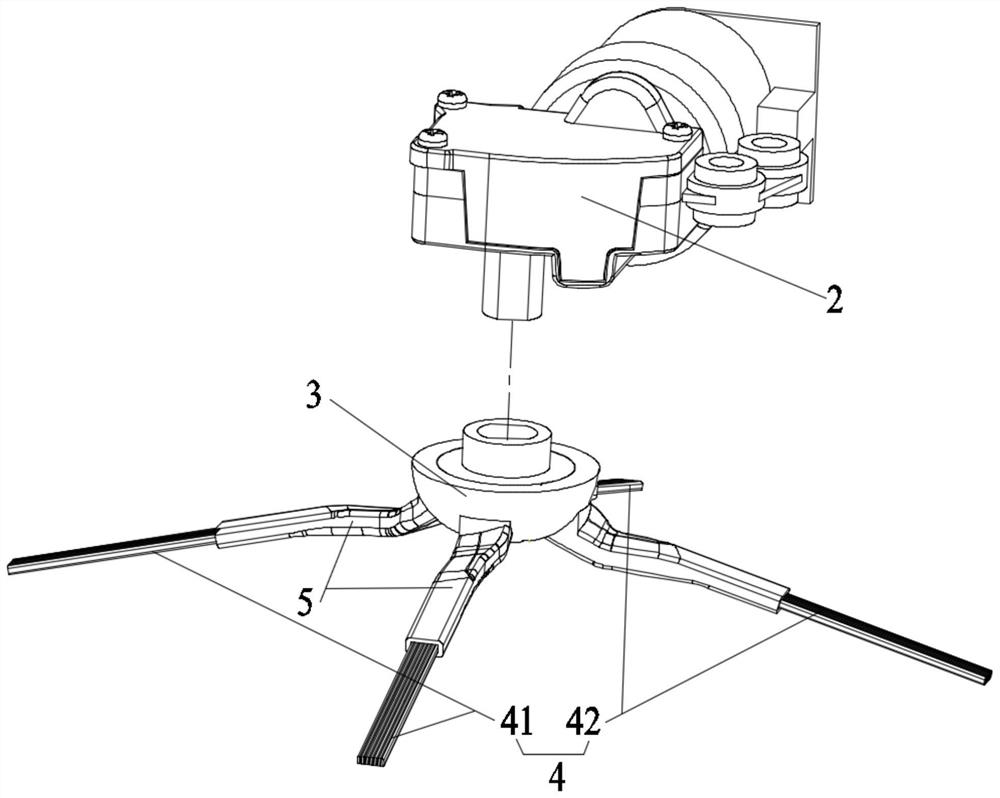

[0053] Such as figure 2 as shown, figure 2 It is a three-dimensional exploded view of the side sweep assembly and the drive assembly of the present invention. The side sweep assembly of the present invention can be connected with the drive assembly 2, as follows.

[0054] The drive assembly 2 can be a drive assembly 2 such as a motor that provides a rotating force, or a drive assembly 2 that provides a single-directional reciprocating force such as an air cylinder or a hydraulic cylinder, or a motor plus a transmission mechanism to provide a single-direction reciprocation Force drive assembly 2. The transmission mechanism is used to convert rotation into translation, such as a belt transmission mechanism.

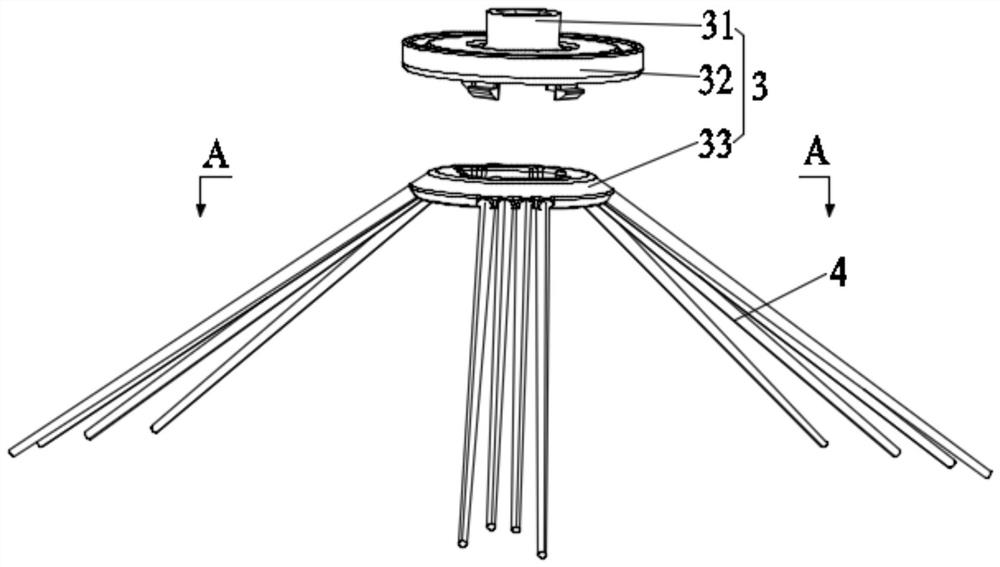

[0055] The side sweep components include:

[0056] Body 3, the body 3 has a connection portion connected to the drive assembly 2, in this embodiment, the connection portion is a groove, the drive assembly 2 is a motor, the output end of the motor has a flat shaft porti...

Embodiment 2

[0087] Such as Figure 10 as shown, Figure 10 It is a structural schematic diagram of the cleaning robot of the present invention.

[0088] The present invention further provides a cleaning robot, including the side sweeping assembly described in the above embodiment, and the side sweeping assembly is arranged at the bottom of the cleaning robot.

[0089] Cleaning robots include:

[0090] Machine main body 6, machine main body 6 can be oval, circular, D-shaped and other shapes, and according to the needs, select settings for installing cleaning modules, walking modules, fan components, control components, distance sensing components, cliff sensors, water tanks and sewage Various parts such as boxes; the cleaning module can include side sweep components and middle sweep components;

[0091] The side sweep assembly, the side sweep assembly can be installed on the edge of the machine body 6 to clean the position that the middle sweep assembly cannot cover, and roll up the obj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com