Crawler-type counterattack mobile crushing and screening station

A mobile crushing, crawler-type technology, applied in grain processing and other directions, can solve the problems of low degree of folding and shrinkage, poor screening effect, low screening efficiency, etc., to achieve improved screening effect, reasonable power distribution, and comprehensive functions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

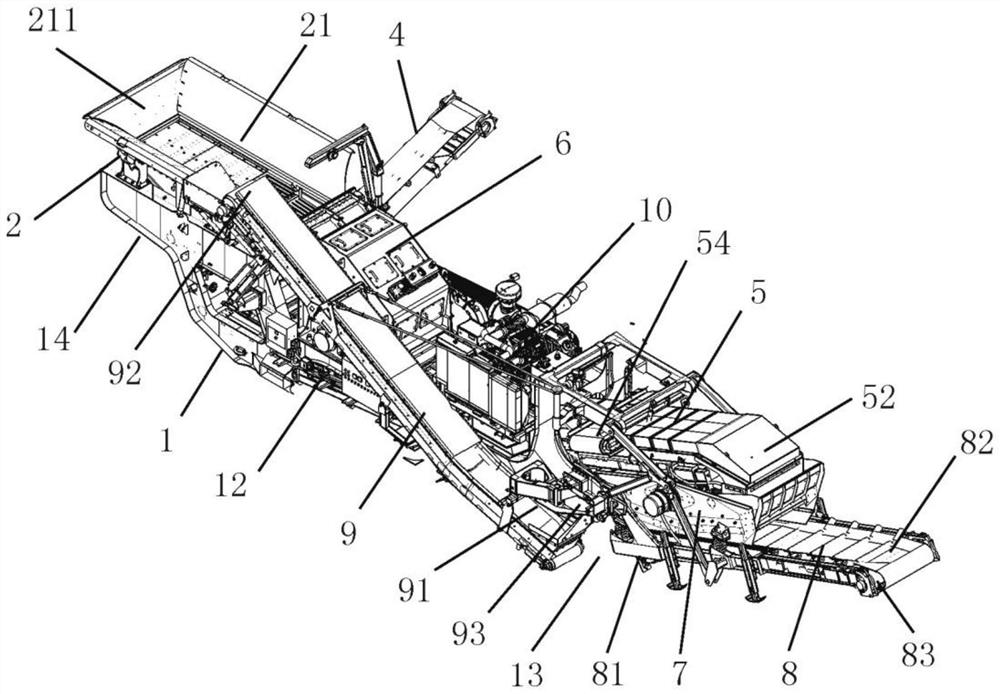

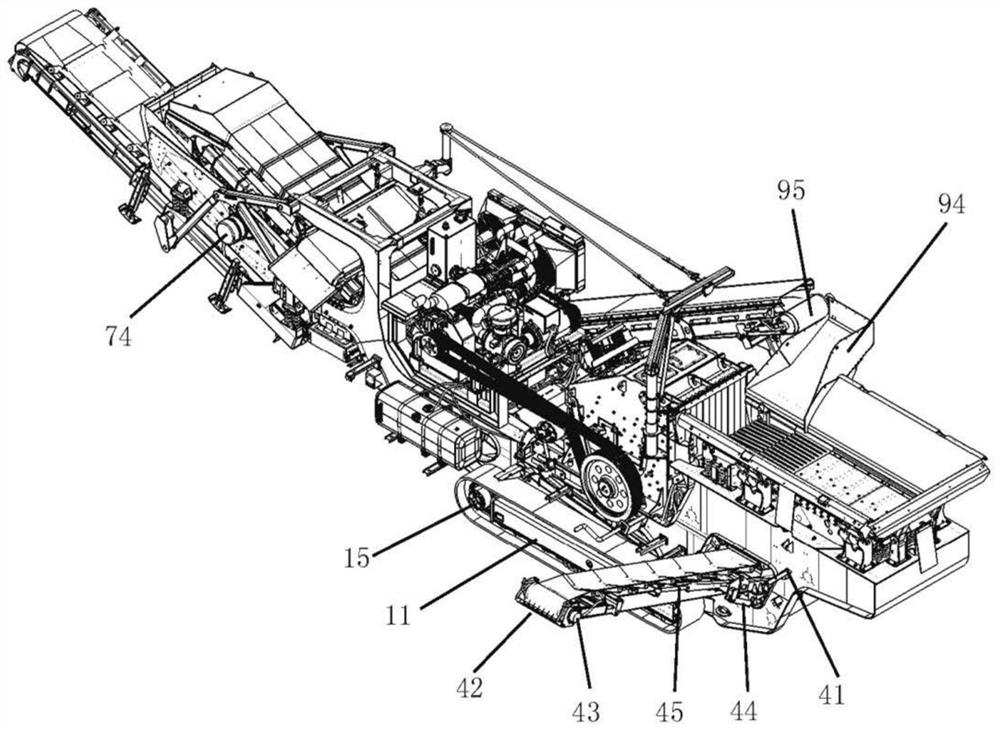

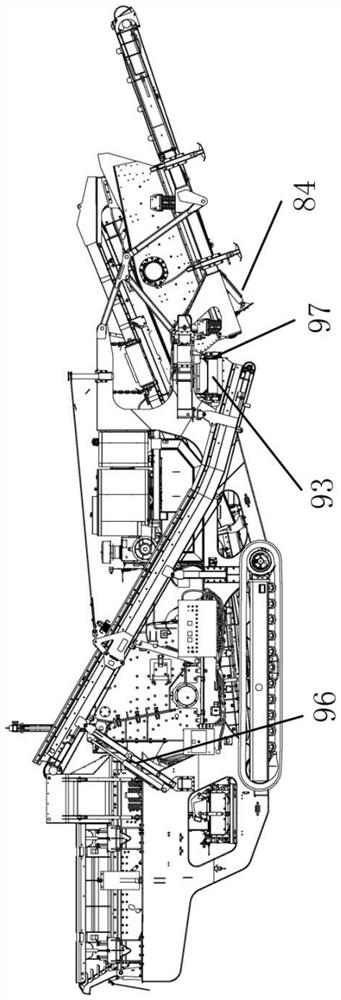

[0043] Such as Figure 1 to Figure 5 As shown, the crawler-type counterattack mobile crushing and screening station in this embodiment includes: a frame 1, a chassis 11, a crawler wheel set 12, a front end 13 of the frame, a rear end 14 of the frame, a crawler motor 15, and a vibrating feeder 2. Feeding hopper 21, bucket plate 211, first hydraulic cylinder 212, feeding hopper inlet 22, first coarse material outlet 23, first medium material outlet 24, first fine material outlet 25, first vibrator 26, distribution hopper 3. Hopper inlet 31, second fine material outlet 32, second middle material outlet 33, tailing belt 4, tailing belt feeding end 41, tailing belt outlet 42, first motorized roller 43, second Hydraulic cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com