Manufacturing method of carbon fiber composite material exhaust pipe

A technology of composite materials and manufacturing methods, which can be applied to other household appliances, household appliances, household components, etc., and can solve the problems of restricting the development of carbon fiber exhaust pipes and the easy deformation of exhaust pipes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

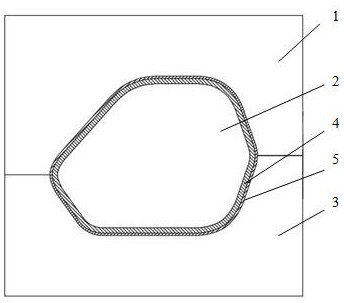

[0015] Such as figure 1 Shown, the present invention is a kind of manufacture method of carbon fiber composite material exhaust pipe, and it comprises the upper mold 1 of making exhaust pipe, lower mold 3 and core mold 2, and its steps are:

[0016] 1. Pour the release agent on the wiping paper, and apply the release agent twice in the cavities of the upper mold 1 and lower mold 3 and on the core mold 2. The interval between coatings is half an hour. The release agent can be released after cooling. When molding, the mold and product can be separated quickly.

[0017] 2. Coat a layer of glue on the mandrel 2, then cut the airgel 4 and lay it in a circle on the mandrel 2. The room temperature thermal conductivity of the airgel 4 is only 0.02K / (m·K), It can prevent the temperature of high-temperature exhaust gas from being transferred to the carbon fiber exhaust pipe body. The thickness of the airgel 4 is 5mm, and the cutting size is 450mmx500mm.

[0018] 3. Lay four pieces of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com