Modified polyolefin composite membrane composition, modified polyolefin composite membrane and preparation method and application thereof

A composite film and composition technology, applied in chemical instruments and methods, applications, flexible coverings, etc., can solve the problems of composite packaging materials in terms of puncture resistance, moisture resistance, water resistance, gas resistance, oxygen resistance, pressure resistance and drop Poor performance, composite packaging materials are not easy to recycle and reuse, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

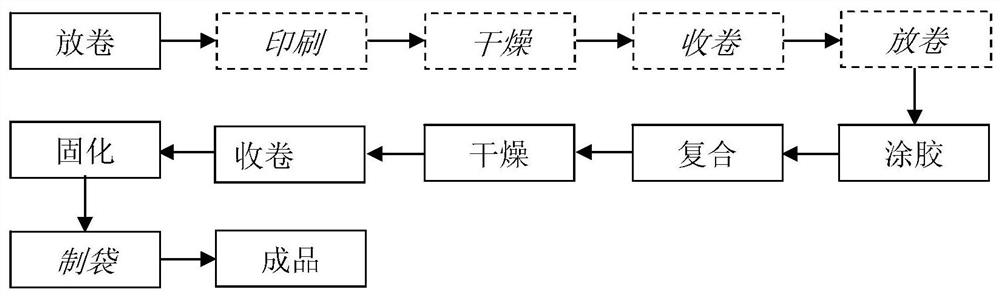

[0051] According to the third aspect of the present invention, the present invention provides a preparation method of the aforementioned composite membrane, wherein the preparation method comprises:

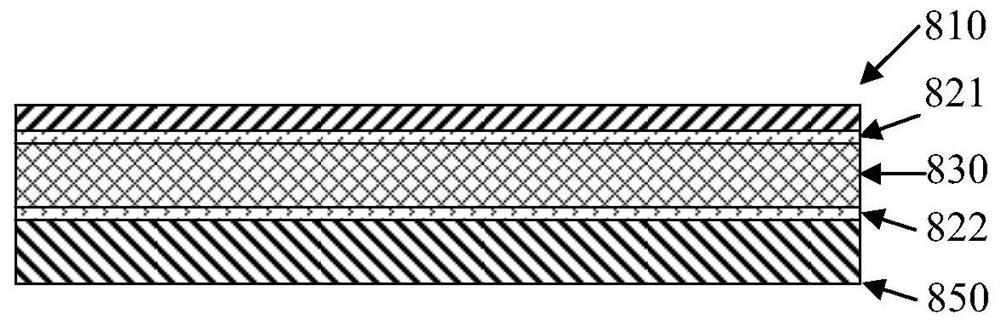

[0052] (1) using the first material to prepare the first layer of film 810;

[0053] (2) using the second material to prepare the interlayer film 830;

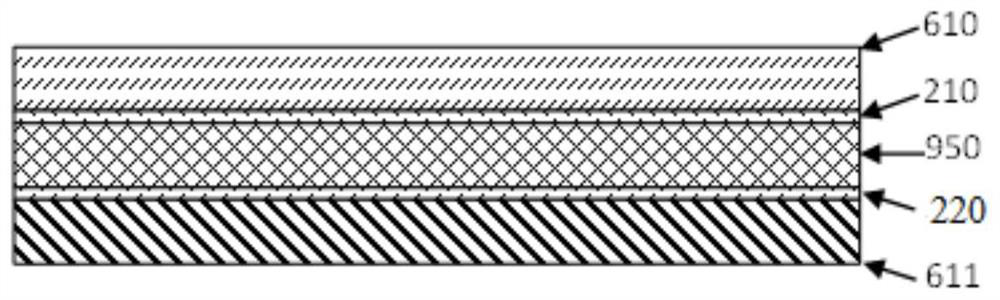

[0054] (3) The third material is used to prepare the PE corona layer 610, the fourth material is used to prepare the thermoplastic barrier layer 950, the fifth material is used to prepare the PE heat sealing layer 611, and the PE corona layer 610, the thermoplastic barrier layer 950 and the The PE heat-sealing layer 611 is sequentially bonded by the first polymer adhesive layer 210 and the second polymer adhesive layer 220 to prepare a third film 850;

[0055] (4) The first layer film 810, the intermediate layer film 830 and the third layer film 850 are sequentially bonded through the first glue layer 821 and the second glue lay...

Embodiment 1

[0102] This example is to illustrate the preparation of the modified polyolefin composite film by using the modified polyolefin composite film composition of the present invention and the preparation method of the present invention.

[0103] (1) The modified polyolefin composite film composition includes:

[0104] The first layer of film material: multi-layer co-extruded biaxially oriented polyethylene (BOPE) film.

[0105] Intermediate film material: multilayer co-extruded biaxially oriented polyethylene vapor-deposited alumina film.

[0106] The third layer of film material:

[0107] PE corona layer material: the first medium density linear polyethylene (MLDPE) and the first anti-blocking masterbatch; based on the total weight of the PE corona layer material, the content of the first medium density linear polyethylene is 96.5% by weight, and the content of the first anti-blocking masterbatch is 3.5% by weight.

[0108] Barrier film material: thermoplastic polyvinyl alcoho...

Embodiment 2

[0129] This example is to illustrate the preparation of the modified polyolefin composite film by using the modified polyolefin composite film composition of the present invention and the preparation method of the present invention.

[0130] (1) The modified polyolefin composite film composition includes:

[0131] The first layer of film material: multi-layer co-extruded biaxially oriented polyethylene (BOPE) film.

[0132] Intermediate film material: multilayer co-extruded biaxially oriented polyethylene vapor-deposited alumina film.

[0133] The third layer of film material:

[0134] PE corona layer material: the first medium density linear polyethylene (MLDPE) and the first anti-blocking masterbatch; based on the total weight of the PE corona layer material, the content of the first medium density linear polyethylene is 80% by weight, and the content of the first anti-blocking masterbatch is 20% by weight.

[0135] Barrier film material: thermoplastic polyvinyl alcohol, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com