Temperature-resistant porphyrin grafted silicon dioxide toner and preparation method and application thereof

A technology of silicon dioxide and porphyrin, applied in the field of anti-counterfeiting, can solve the problems of unsatisfactory temperature resistance of toner, unsustainable temperature resistance of toner, chemical oxidation and carbonization, etc., and achieve simple and efficient preparation method and excellent temperature resistance , the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

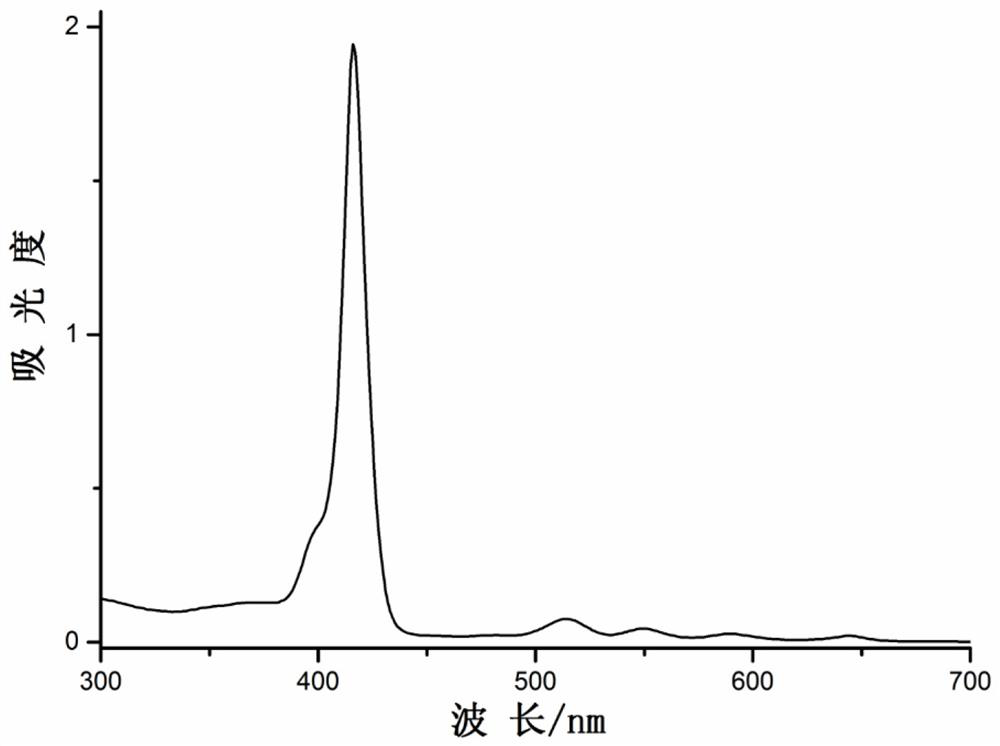

[0029] Modification of carboxyl group and (3-aminopropyl) triethoxysilane group on porphyrin dye to obtain temperature-resistant porphyrin; the structure is shown in (II) below.

[0030] Synthesis of the heat-resistant porphyrin grafted silica toner of formula (II):

[0031]

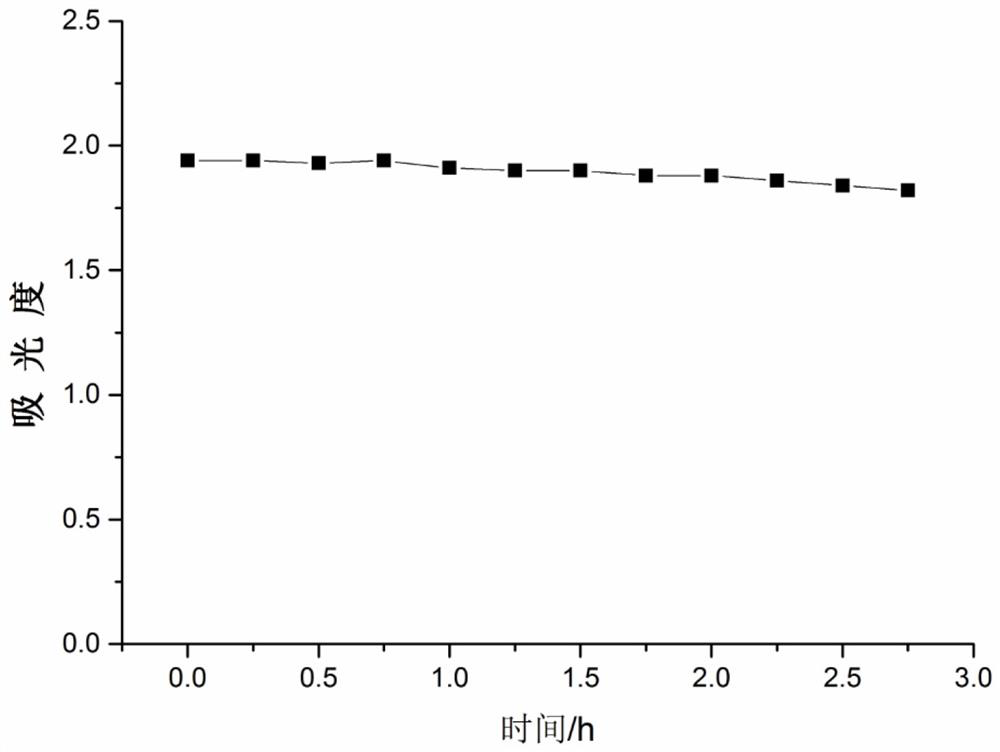

[0032] Mix n-heptane, n-heptanol and surfactant Triton X-100 uniformly in a certain proportion, add an appropriate amount of water as a dispersed phase, then add a certain amount of heat-resistant porphyrin (II), stir for 5 minutes, and form Water-in-oil microcapsules, and then ethyl orthosilicate is added to the microcapsule system, after stirring evenly, an appropriate amount of lye is added for hydrolysis, and the entire reaction time is 8 hours. In the reaction system, the ratio of the amount of n-heptanol, n-heptane, surfactant triton X-100, water, temperature-resistant porphyrin, tetraethyl orthosilicate, and lye is 1:4:0.5:2.5: 0.1:1:1.1. After the reaction is completed, centrifuge and dry to...

Embodiment 2

[0035] The synthesis of the heat-resistant porphyrin grafted silica toner of formula (III) structure:

[0036]

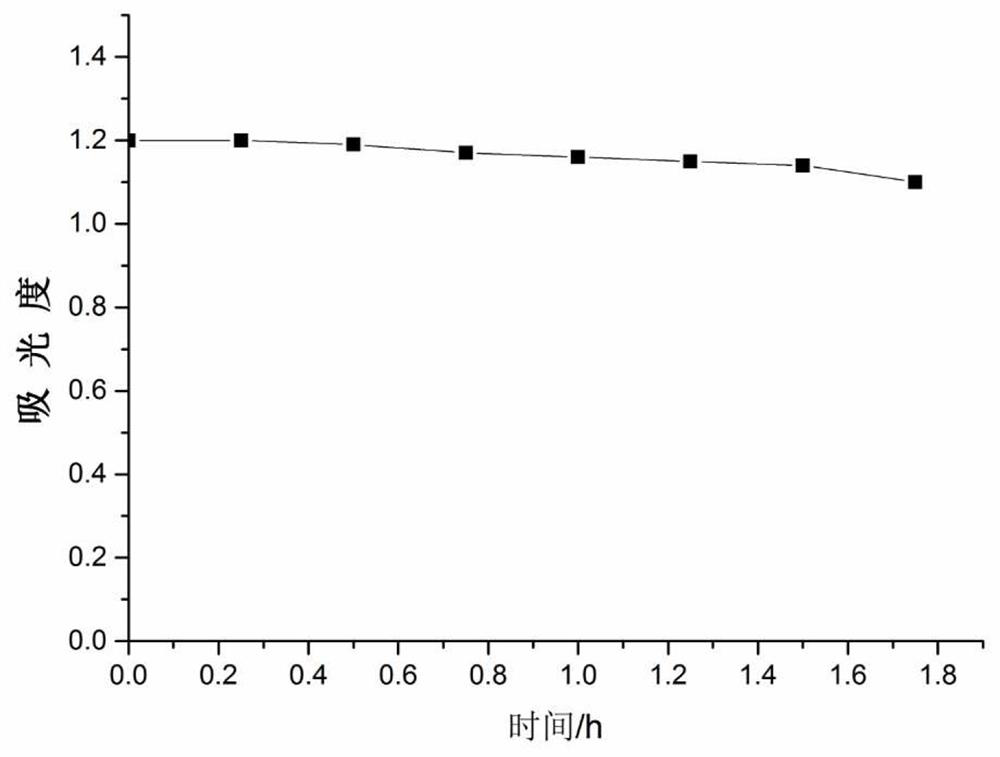

[0037] Mix n-heptane, n-heptanol and surfactant Triton X-100 uniformly in a certain proportion, add an appropriate amount of water as a dispersed phase, then add a certain amount of heat-resistant porphyrin (III), stir for 5 minutes, and form Water-in-oil microcapsules, and then ethyl orthosilicate is added to the microcapsule system, after stirring evenly, an appropriate amount of lye is added for hydrolysis, and the whole reaction time is 16 hours. In the reaction system, the ratio of the amount of n-heptanol, n-heptane, surfactant triton X-100, water, temperature-resistant porphyrin, tetraethyl orthosilicate, and lye is 1:1:1:3.5: 0.2:3:5. After the reaction is completed, centrifuge and dry to obtain heat-resistant porphyrin-silicon dioxide toner with a yield of 89%.

[0038] The temperature-resistant porphyrin-silica toner obtained in Example 2 is the holog...

Embodiment 3

[0040] The synthesis of the heat-resistant porphyrin grafted silica toner of formula (IV) structure:

[0041]

[0042] Mix n-heptane, n-heptanol and surfactant Triton X-100 uniformly in a certain proportion, add an appropriate amount of water as a dispersed phase, then add a certain amount of heat-resistant porphyrin (IV), stir for 5 minutes, and form For water-in-oil microcapsules, add tetraethyl orthosilicate into the microcapsule system, stir evenly, add an appropriate amount of lye for hydrolysis, and the entire reaction time is 20 hours. In the reaction system, the ratio of the amount of n-heptanol, n-heptane, surfactant triton X-100, water, temperature-resistant porphyrin, tetraethyl orthosilicate, and lye is 1:10:4:10: 0.5:10:11. After the reaction is completed, centrifuge and dry to obtain heat-resistant porphyrin-silicon dioxide toner with a yield of 95%.

[0043] The temperature-resistant porphyrin-silica toner obtained in Example 3 is a holographic water transf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com