Harmless treatment system and process for tank cleaning oil sludge

A technology of harmless treatment and sludge treatment, applied in the fields of sludge treatment, water/sludge/sewage treatment, pyrolysis treatment of sludge, etc., can solve the problems of substandard, difficult to deal with oily sludge in tank cleaning, etc., and reduce the work intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

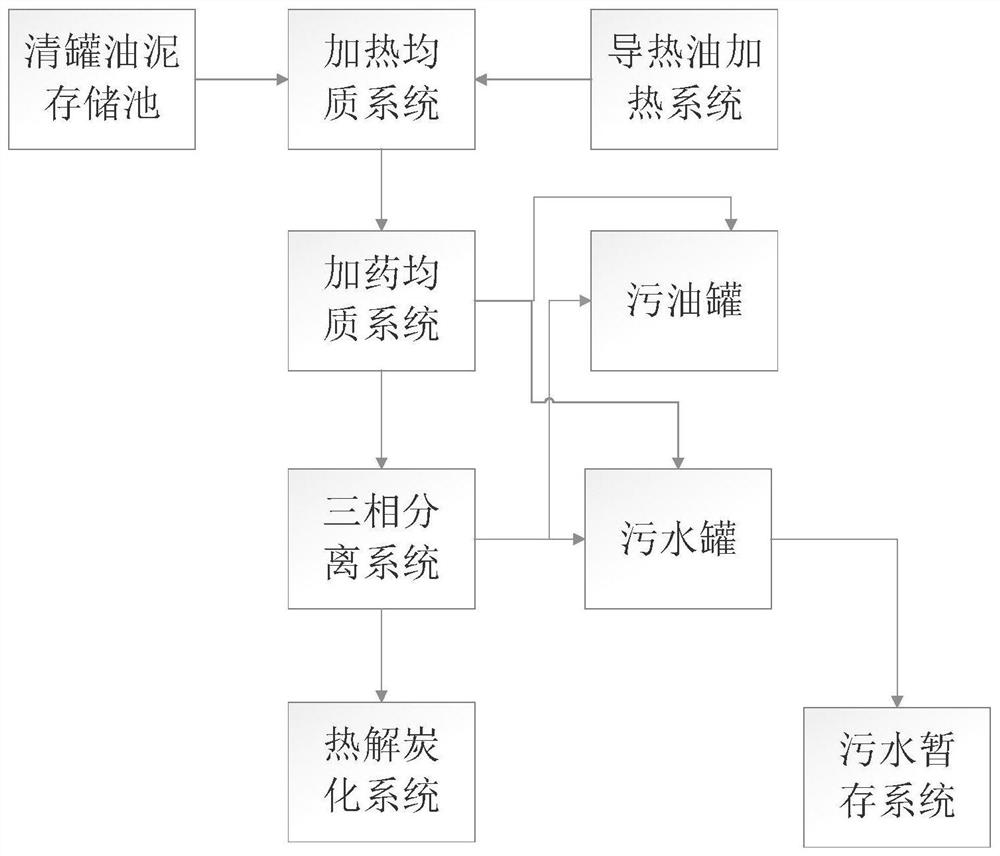

[0023] like figure 1 As shown in the figure, a harmless treatment system for tank cleaning sludge includes a tank cleaning sludge storage tank and a heating and homogenizing system (simple filtration of tank cleaning sludge through a grille, heating the sludge to 60°C by turning on the heat conduction oil boiler, stirring evenly It is convenient for the follow-up process after being refined, and the slurry pump is used to introduce the chemical dosing homogeneous system), the heat transfer oil heating system (the heated heat transfer oil is transported to the part that needs to be heated through the pipeline), the chemical dosing homogeneous system (adding heat to the processing system) medicine, adjust the solid-liquid ratio in the homogeneous system to meet the requirements of the subsequent centrifuge), three-phase separation system (the oil, water, and mud in the homogeneous system are separated twice, and the separated oil enters the crude oil tank, the sewage enters the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com