Nano silver powder conductive adhesive with good conductivity

A technology of nano silver powder and conductive adhesive, applied in conductive adhesives, adhesives, epoxy resin adhesives, etc., can solve problems such as poor electrical conductivity, and achieve the effect of improving electrical conductivity and reducing contact resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

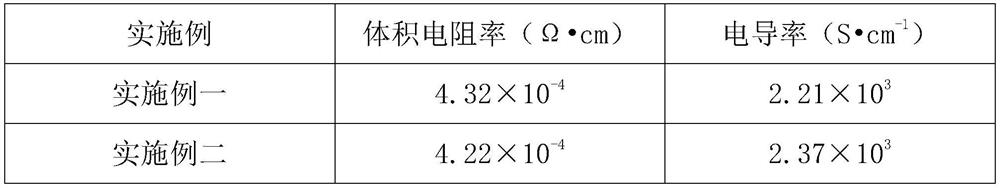

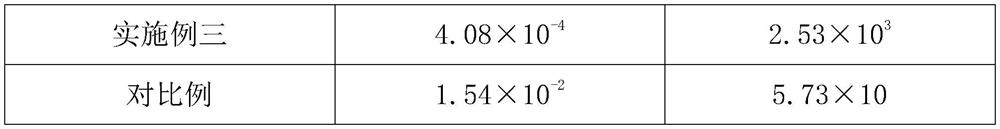

Embodiment 1

[0023] The nano-silver powder conductive adhesive includes the following raw materials in parts by weight: 100g of epoxy resin E-51 matrix resin, 98g of methyl hexahydrophthalic anhydride (MeHHPA) curing agent, 0.67g of 2-ethyl- 4-methylimidazole (2E4MZ) curing accelerator, composite self-sintering surfactant composed of 3g of benzyltriethylammonium chloride and 2g of tetrabutylammonium hydrogensulfate, 140g of silver powder with an average particle size ≤ 100nm Conductive filler, 1g of malonic acid conduction accelerator, 2g of r-aminopropyltriethoxysilane coupling agent, 1g of phenylhydroquinone antioxidant, 2g of silicone compound defoamer;

[0024] The preparation method of above-mentioned nano-silver powder conductive adhesive comprises the following steps:

[0025] Step 1: Weigh 100g of epoxy resin E-51 base resin, 98g of methylhexahydrophthalic anhydride (MeHHPA) curing agent, and 0.67g of 2-ethyl-4-methylimidazole (2E4MZ) in sequence Put the curing accelerator into th...

Embodiment 2

[0030] The nano-silver powder conductive adhesive includes the following raw materials in parts by weight: 100g of epoxy resin E-51 matrix resin, 98g of methyl hexahydrophthalic anhydride (MeHHPA) curing agent, 0.67g of 2-ethyl- 4-Methylimidazole (2E4MZ) curing accelerator, composite self-sintering surfactant composed of 1g of benzyltriethylammonium chloride and 4g of tetrabutylammonium hydrogensulfate, 150g of silver powder with an average particle size ≤ 100nm Conductive filler, 1g of malonic acid conduction accelerator, 2g of r-aminopropyltriethoxysilane coupling agent, 1g of phenylhydroquinone antioxidant, 2g of silicone compound defoamer;

[0031] The preparation method of above-mentioned nano-silver powder conductive adhesive comprises the following steps:

[0032] Step 1: Weigh 100g of epoxy resin E-51 base resin, 98g of methylhexahydrophthalic anhydride (MeHHPA) curing agent, and 0.67g of 2-ethyl-4-methylimidazole (2E4MZ) in sequence Put the curing accelerator into th...

Embodiment 3

[0037] The nano-silver powder conductive adhesive includes the following raw materials in parts by weight: 100g of epoxy resin E-51 matrix resin, 98g of methyl hexahydrophthalic anhydride (MeHHPA) curing agent, 0.67g of 2-ethyl- 4-methylimidazole (2E4MZ) curing accelerator, composite self-sintering surfactant composed of 3g of benzyltriethylammonium chloride and 1g of tetrabutylammonium hydrogensulfate, 165g of silver powder with an average particle size ≤ 100nm Conductive filler, 1g of malonic acid conduction accelerator, 2g of r-aminopropyltriethoxysilane coupling agent, 1g of phenylhydroquinone antioxidant, 2g of silicone compound defoamer;

[0038] The preparation method of above-mentioned nano-silver powder conductive adhesive comprises the following steps:

[0039] Step 1: Weigh 100g of epoxy resin E-51 base resin, 98g of methylhexahydrophthalic anhydride (MeHHPA) curing agent, and 0.67g of 2-ethyl-4-methylimidazole (2E4MZ) in sequence Put the curing accelerator into th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com