Variable-density three-dimensional fabric and weaving method thereof

A three-dimensional fabric and variable density technology, which is applied in fabrics, textiles, papermaking, textiles, etc., can solve problems such as single structure, inability to realize continuous weaving, and single density change form

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

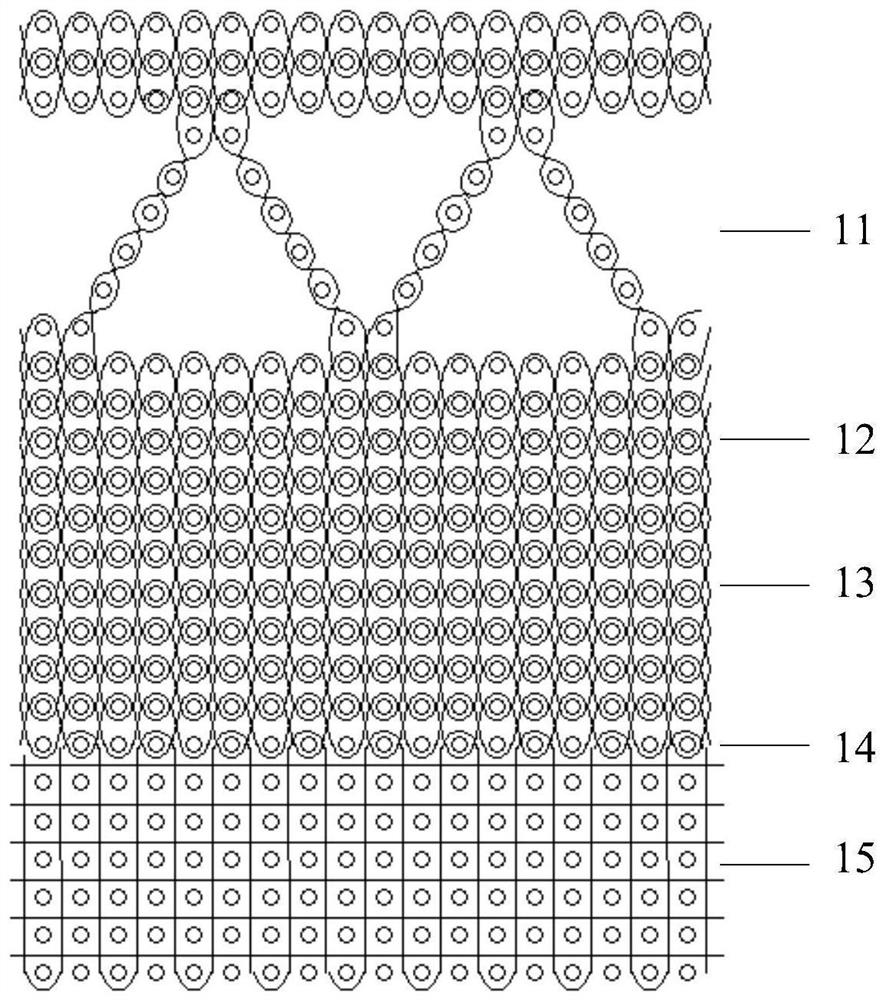

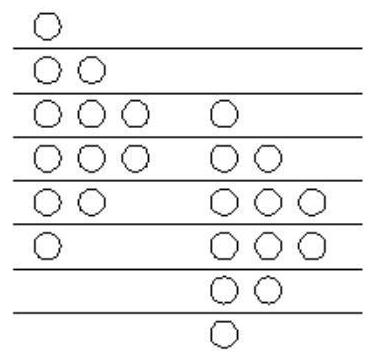

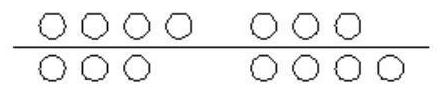

[0044] refer tofigure 1 , this embodiment provides a three-dimensional fabric with variable density along the thickness direction. This embodiment realizes the density change of the fabric along the three regions of the thickness direction through the change of the structure and the change of the weft yarn density. The structure of the first density zone 11 is a hollow interlayer , the tissue structure of the second density zone 13 is shallow cross-curved joints, the tissue structure of the third density zone 15 is an orthogonal three-way, and the interface connection 12 between the first density zone and the second density zone is connected by a shallow cross-curved structure , the interface connection 14 between the second density area and the third density area is connected by a shallow cross-bending structure, and the yarns are continuous.

[0045] In this embodiment, the variable-density three-dimensional fabric is woven with 500tex glass fiber.

[0046] The process param...

Embodiment 2

[0062] refer to Figure 11 , this embodiment provides a three-dimensional fabric with variable density along the thickness direction and the width direction at the same time, through the structure change, warp density change, yarn fineness change, and yarn type change, the fabric can be realized in three regions along the thickness direction and along the width. The density changes in the three regions in the thickness direction, the tissue structure of the first density zone 21 in the thickness direction is an orthogonal three-dimensional structure, the tissue structure of the second density zone 23 in the thickness direction is shallow cross-curved joints, and the tissue structure of the third density zone 25 in the thickness direction It is a shallow intersection and direct connection, the interface connection 22 between the first density region and the second density region in the thickness direction is connected by a shallow cross-bend structure, and the interface connecti...

Embodiment 3

[0080] refer to Figure 16 , this embodiment provides a three-dimensional fabric with variable density along the thickness direction and along the length direction at the same time, through the change of the structure, the change of the weft yarn density, and the change of the number of yarn strands, the fabric can be realized in two regions along the thickness direction and along the length direction. Density changes in the two areas, the tissue structure of the first density zone 31 in the thickness direction is an orthogonal three-dimensional structure, the tissue structure of the second density zone 33 in the thickness direction is a shallow cross-bending joint, and the interface between the first density zone and the second density zone The joint 32 is connected by a shallow cross-bending structure. The first density zone in the length direction uses a yarn share ratio of 1:1, and the second density zone in the length direction uses a yarn share ratio of 1:2. Different str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com