Full-thickness ultrathin long-service-life pavement structure and construction method thereof

A pavement structure, long-life technology, applied in chemical instruments and methods, roads, roads, etc., can solve the problems of easy reflection of cracks in the base layer to the surface layer, easy occurrence of ruts and pothole diseases, and inability to ensure construction quality. The effect of obvious synergy between layers, high bonding strength between layers, and reducing the thickness of pavement structural layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Example 1 Preparation of full-thickness ultra-thin long-life pavement structure

[0044] 1. Pavement structure composition

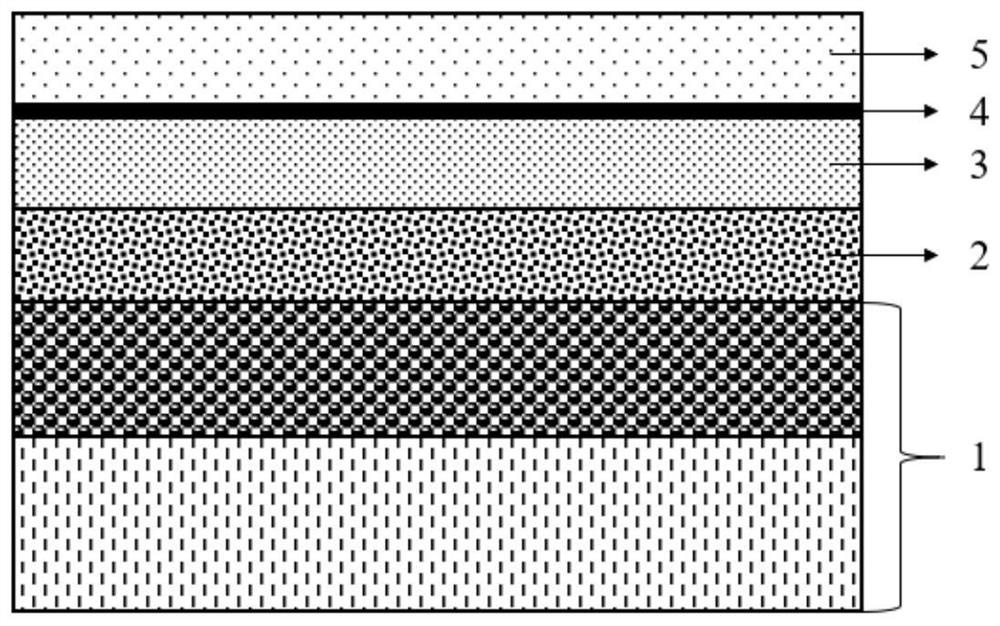

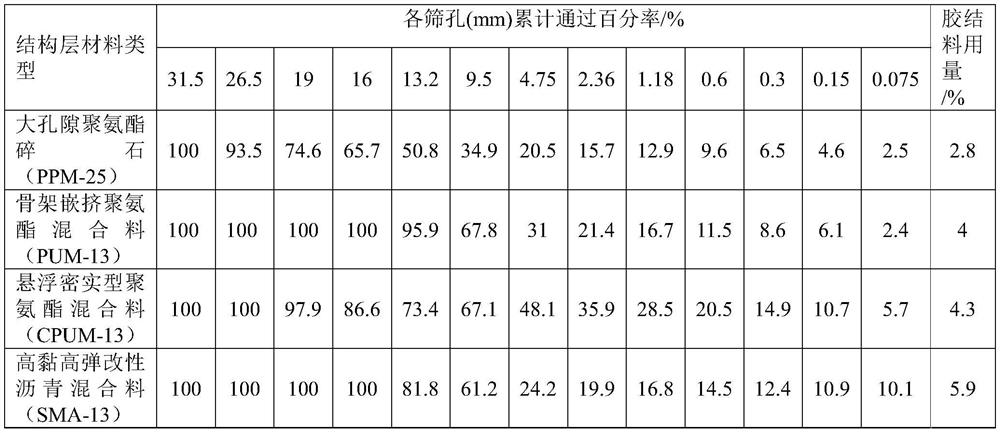

[0045] as attached figure 1 As shown, the full-thick ultra-thin long-life pavement structure of this embodiment is paved from bottom to top by a composite coupling layer 1, an anti-fatigue layer 2, a load-bearing layer 3, a high-strength bonding layer 4 and an anti-skid wear layer 5. On top of the embankment. The composite coupling layer consists of a graded crushed stone layer and an open-graded large-size permeable polyurethane crushed stone mixture layer from bottom to top. The technical indicators of the graded crushed stone layer are shown in Table 1. The open-graded large-diameter permeable polyurethane gravel mixture layer is prepared by mixing the mineral material and the polyurethane cement in proportion to a skeleton pore structure mixture with a porosity of 15% to 20%. The mineral material is composed of 0~3mm, 3~5mm, 5~10mm, 10~20mm...

Embodiment 2

[0075] Embodiment 2 Comparison of full-thickness ultra-thin long-life pavement structures

[0076] 1. Advantages of pavement structure composition

[0077] The typical full-thickness long-life asphalt pavement and combined long-life asphalt pavement are selected for comparative analysis. The pavement structure is shown in Table 6. The total thickness of the full-thickness ultra-thin long-life asphalt pavement is only 81.0% and 41.5% of the structure two and three. The thickness of the long-life pavement has been greatly reduced.

[0078] Table 6 Pavement structure and thickness

[0079]

[0080] 2. Cost advantage of pavement structure

[0081] Taking an expressway with a length of 1km and a width of 25m as an example, according to the current market price of materials, the amount and cost of various materials for the three pavement structures proposed in Table 6 are calculated, and the calculation results are shown in Table 7.

[0082] Table 7 Consumption and cost of three...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com