Oil absorption and impurity removal type resin adsorption hemisphere

A resin adsorption and impurity removal technology, applied in the field of oil-absorbing resin, can solve the problems of reducing oil absorption rate, recovery of difficult oil pollution, deoiling treatment, etc., and achieve the effect of improving oil absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

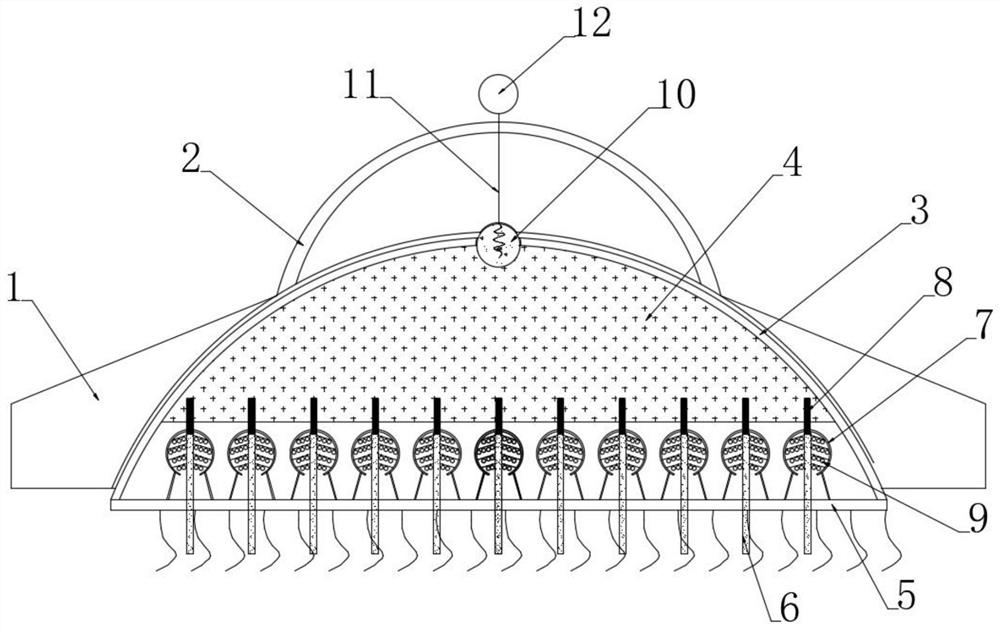

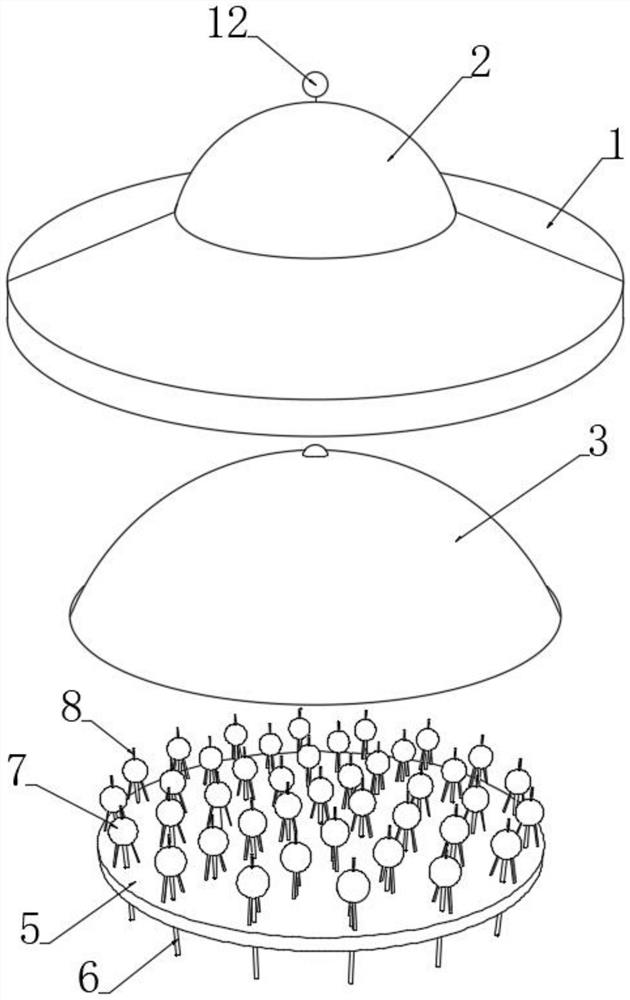

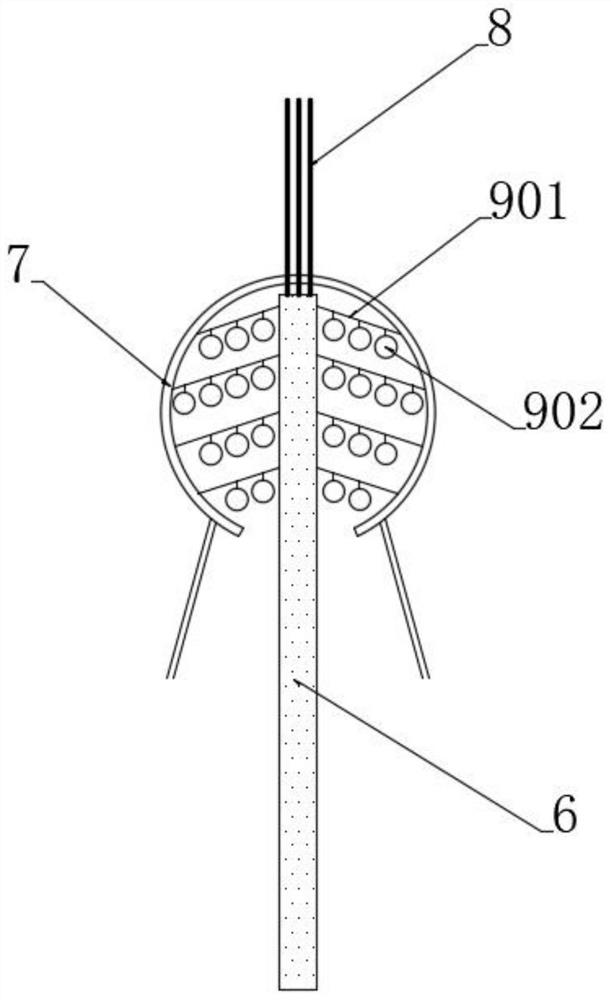

[0043] see Figure 1-2 , an oil-absorbing and impurity-removing resin adsorption hemisphere, including a floating plate 1 and a floating ball 2 installed on the top of the floating plate 1, the inside of the floating plate 1 is fixedly embedded with an elliptical oil collecting plate 3, and the elliptical oil collecting plate 3 The inner top is filled with resin oil-absorbing cotton 4, and the inside of the floating ball 2 is filled with air flotation gas. The air flotation gas is made of hydrogen and inert gas with a mass ratio of 2:1. The cooperation of the floating ball 2 and the floating plate 1 realizes the device It can be stably suspended above the water surface, and the bottom end of the elliptical oil collecting plate 3 is fixedly connected with an adsorption fiber layer 5, and a plurality of oil dirt adsorption bodies are distributed on the adsorption fiber layer 5, and the bottom end of the adsorption fiber layer 5 is placed on the water surface, And the bottom of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com