Metal window with thermal bridge partition structure

A metal window and metal technology, which is applied in the direction of windows/doors, building components, window/door frames, etc., can solve the problems of unfavorable production and processing of segmented structures, increase the difficulty of assembly and installation, etc., achieve convenient maintenance and modification, reduce Production difficulty and cost, and the effect of reducing assembly difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

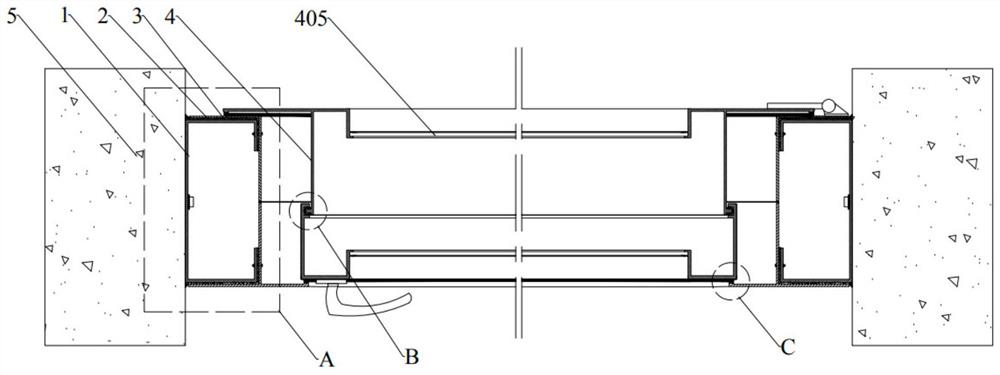

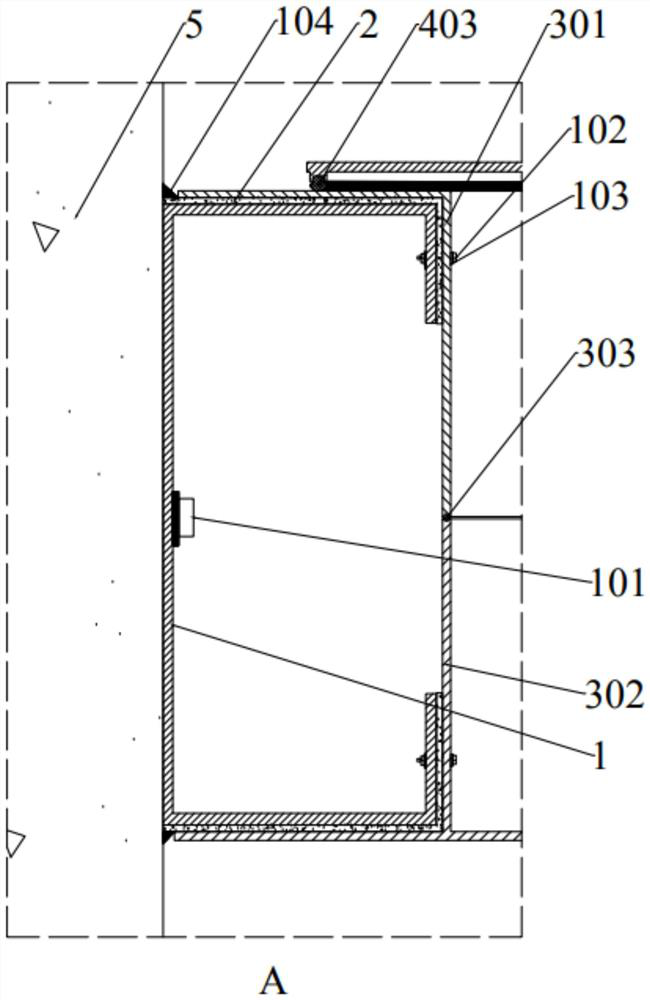

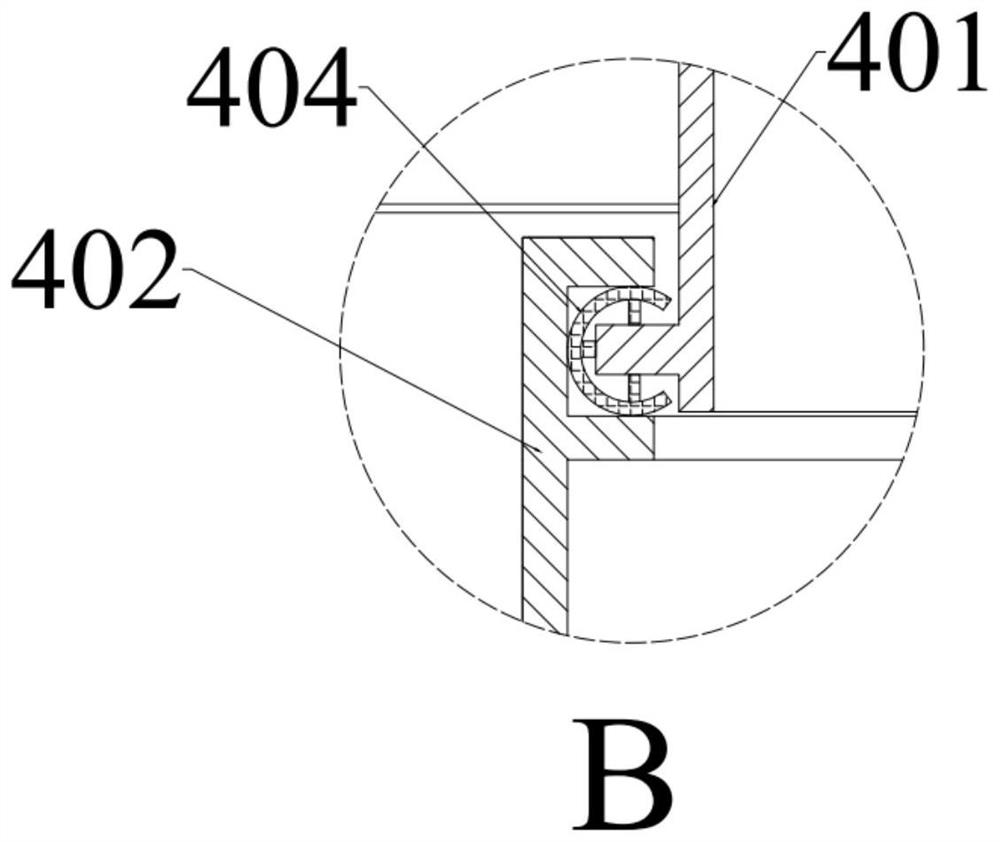

[0032] The following is combined with the specific Figure 1-6 Specific examples of the present invention will be described.

[0033] A metal window with a heat-insulating bridge structure, comprising: a metal window frame 3 and a metal window 4;

[0034] Such as figure 1 As shown, it also includes: an outer frame skeleton 1 and a heat insulation layer 2 . combine figure 2 As shown, the outer frame skeleton 1 is a square frame structure with a U-shaped cross section, and the U-shaped opening faces the center of the frame body; preferably, the end of the outer frame skeleton 1 section is bent inward to form a 90° folded edge, And keep the opening width to meet the installation needs. The bottom surface inside the outer frame 1 is fixedly connected to the wall 5 through a plurality of expansion bolts 101; preferably, the joint between the outer frame 1 and the wall 5 is coated with sealant.

[0035] The metal window frame 3 is a spliced structure, and the overall section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com