Blade leading edge corrosion monitoring method and system

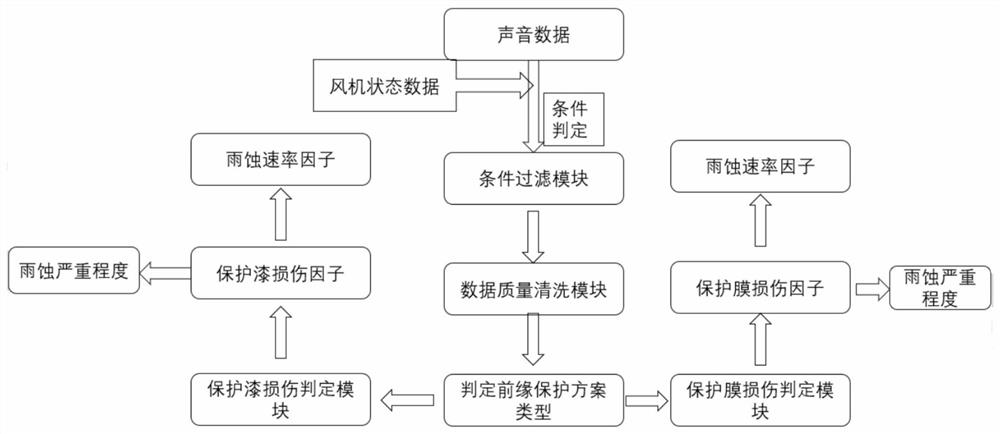

A technology of blade leading edge and monitoring system, applied in wind turbine monitoring, measurement device, control algorithm type, etc., to avoid the increase of fatigue load, avoid serious corrosion, and improve the quality of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

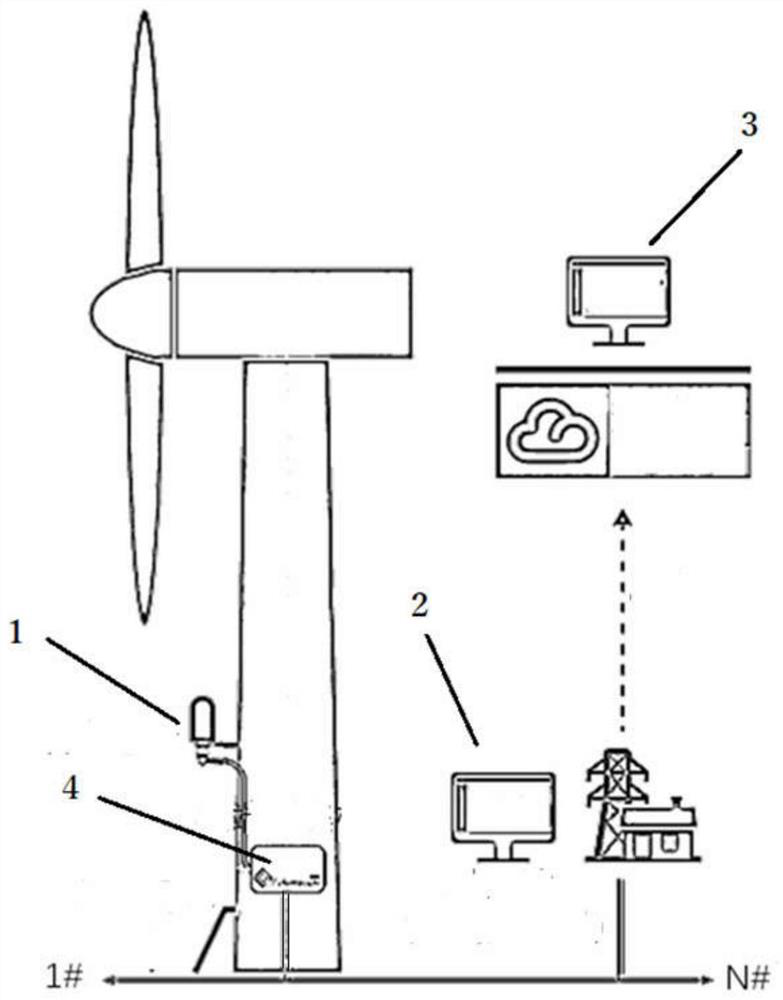

[0144] Taking the blades of a 1.5MW wind turbine in a high rain erosion wind field as an example, the sensors of the monitoring system are installed at a suitable position at the bottom of the tower. The position of the main wind direction of the fan is determined. The sensor is fixed on the bracket, and the bracket is pasted on the outer surface of the tower through magnetic attraction and structural glue, and the sensor is connected to the collection cabinet through the signal line. The collection cabinet is arranged on the bottom platform of the tower through bolt connection, and the collection cabinet enters the wind farm ring network through the network port and the wind farm ring network router at the bottom of the tower. The server is arranged in the booster station and connected to the ring network of the wind field. The server is connected to the SCADA of the wind field conventional monitoring system. It communicates with Scada through the Modbus soft gateway to obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com