Hard mask composition, hard mask layer, and method of forming pattern

A technology of composition and hard mask, which is applied in the photolithographic process of patterned surface, photosensitive materials used in optomechanical equipment, instruments, etc., and can solve the problems such as difficulty in providing fine patterns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

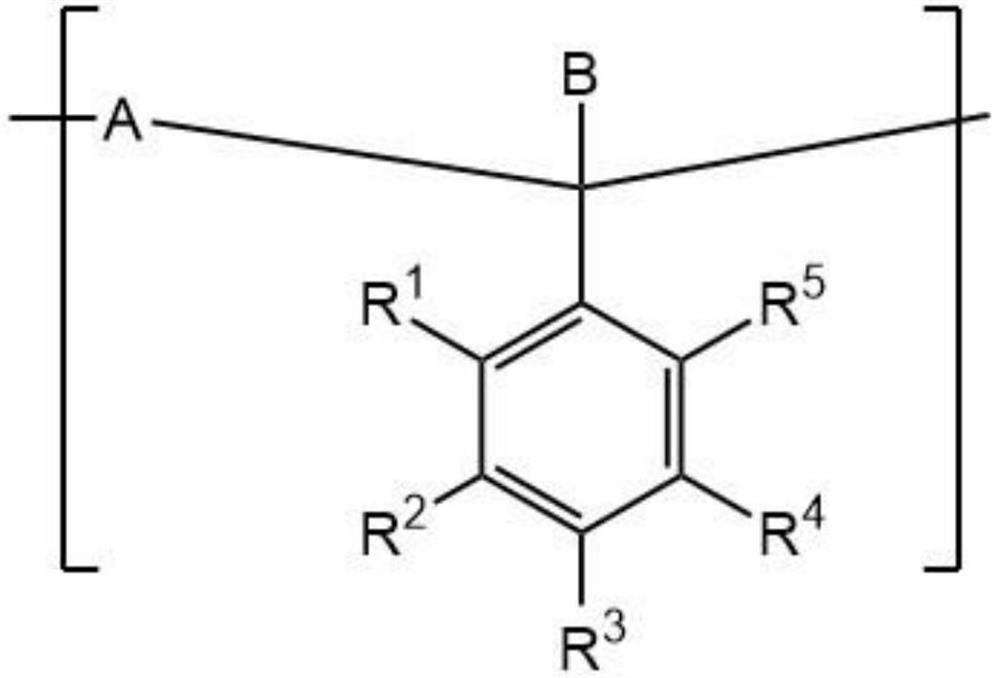

[0136] 1-Hydroxypyrene (21.8 g, 0.1 mol) and 3,4-dihydroxybenzaldehyde (13.8 g, 0.1 mol) were added to a 250-mL flask, and then, to it was added A solution prepared by dissolving p-toluenesulfonic acid monohydrate (0.57 g, 0.03 mmol) in propylene glycol monomethyl ether acetate (PGMEA). The obtained mixture was stirred at 90° C. to perform a polymerization reaction, and when the weight average molecular weight reached 2,000 to 2,500, the reaction was completed. When the polymerization reaction was completed, the reactant was cooled to room temperature, and then, 300 g of distilled water and 300 g of methanol were added thereto, and then vigorously stirred and allowed to stand. After removing the supernatant therefrom, the precipitate therein was dissolved in 100 g of PGMEA, 300 g of methanol and 300 g of distilled water were added thereto, and then vigorously stirred and allowed to stand (primary process). After removing the supernatant again, the precipitate therein was diss...

Synthetic example 2

[0140] Except using 4-hydroxyl-3-methoxybenzaldehyde (15.2 grams, 0.1 mole) instead of 3,4-dihydroxybenzaldehyde (13.8 grams, 0.1 mole), according to the same method as Synthetic Example 1, the compound containing A polymer of a structural unit (repeating unit) represented by Chemical Formula 1b. (Mw: 2,785)

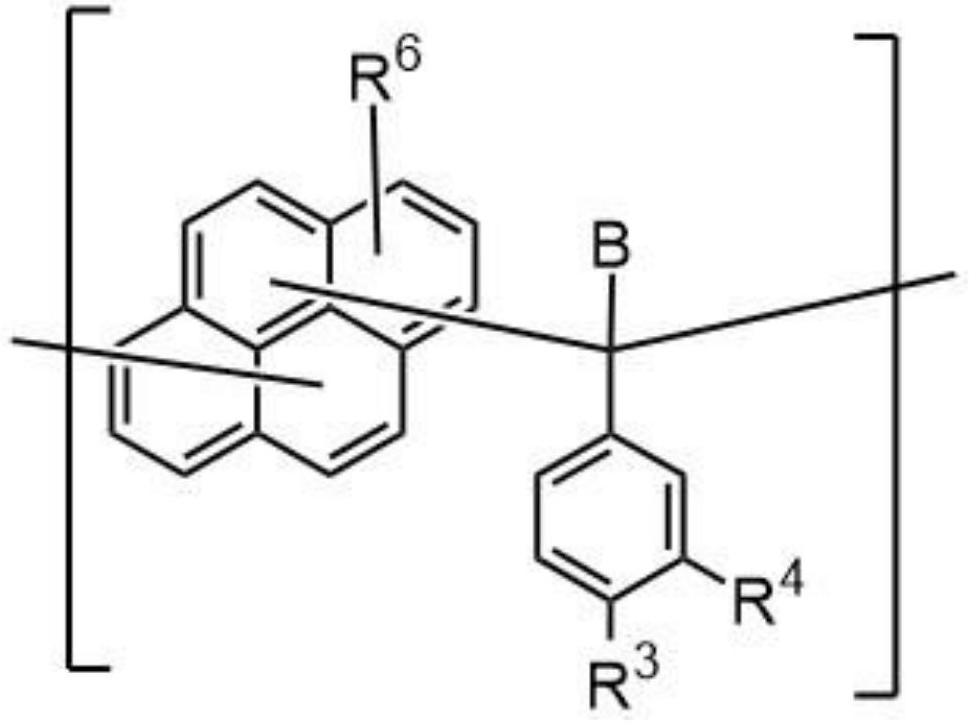

[0141] [chemical formula 1b]

[0142]

Synthetic example 3

[0144] Except using 2,4,6-trihydroxybenzaldehyde (15.4 grams, 0.1 mole) instead of 3,4-dihydroxybenzaldehyde (13.8 grams, 0.1 mole), according to the same method as Synthetic Example 1, the compound containing A polymer of structural units (repeating units) represented by 1c. (Mw: 2,127)

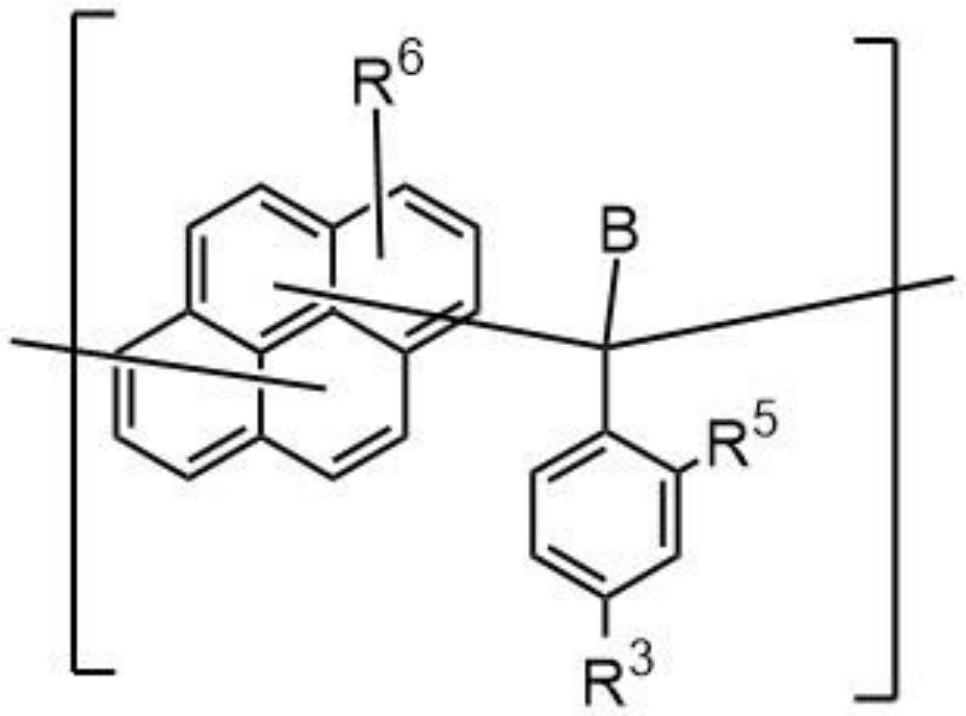

[0145] [chemical formula 1c]

[0146]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com