High-temperature-resistant fireproof flexible cable and manufacturing method thereof

A high-temperature-resistant, flexible cable technology, which is applied in the field of fire-resistant flexible cables and high-temperature-resistant fire-resistant flexible cables, can solve the problems of frequent replacement, large waste, and burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the technical solutions of the present invention clearer and clearer to those skilled in the art, the present invention will be further described in detail below in conjunction with the examples and accompanying drawings, but the embodiments of the present invention are not limited thereto.

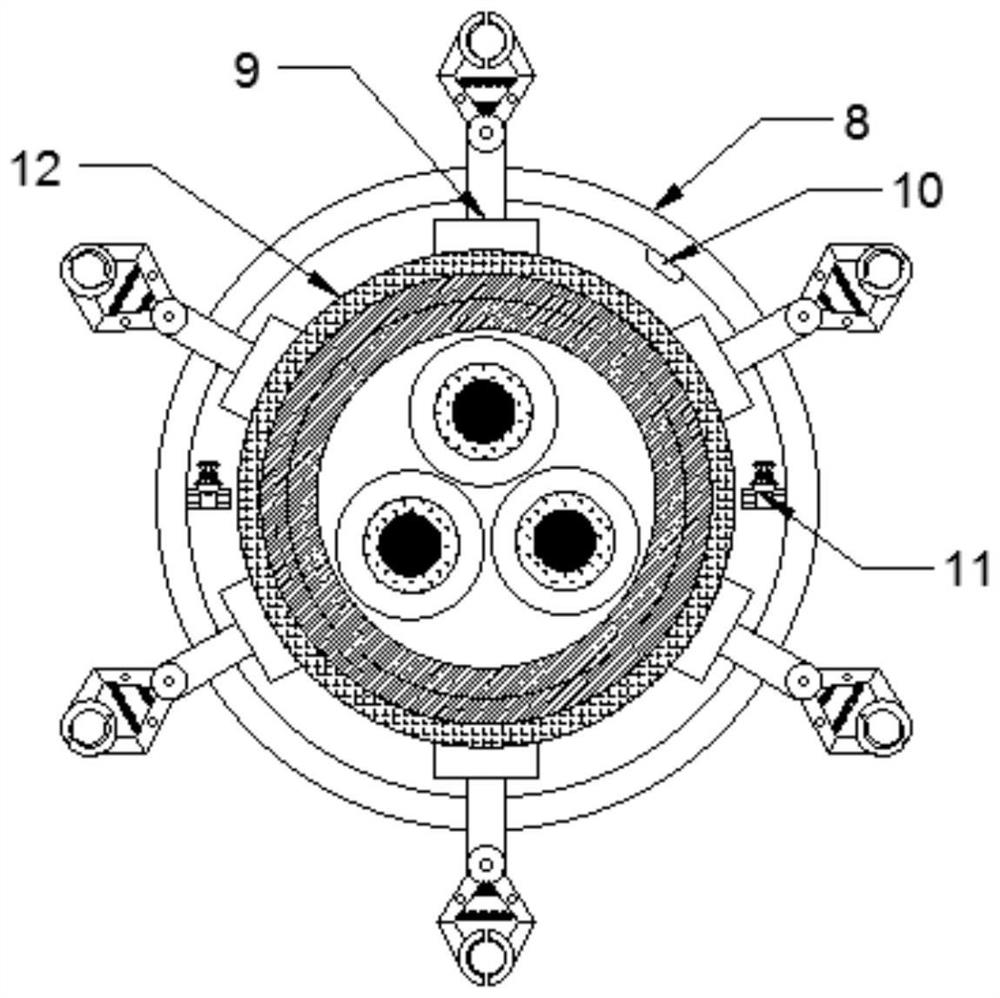

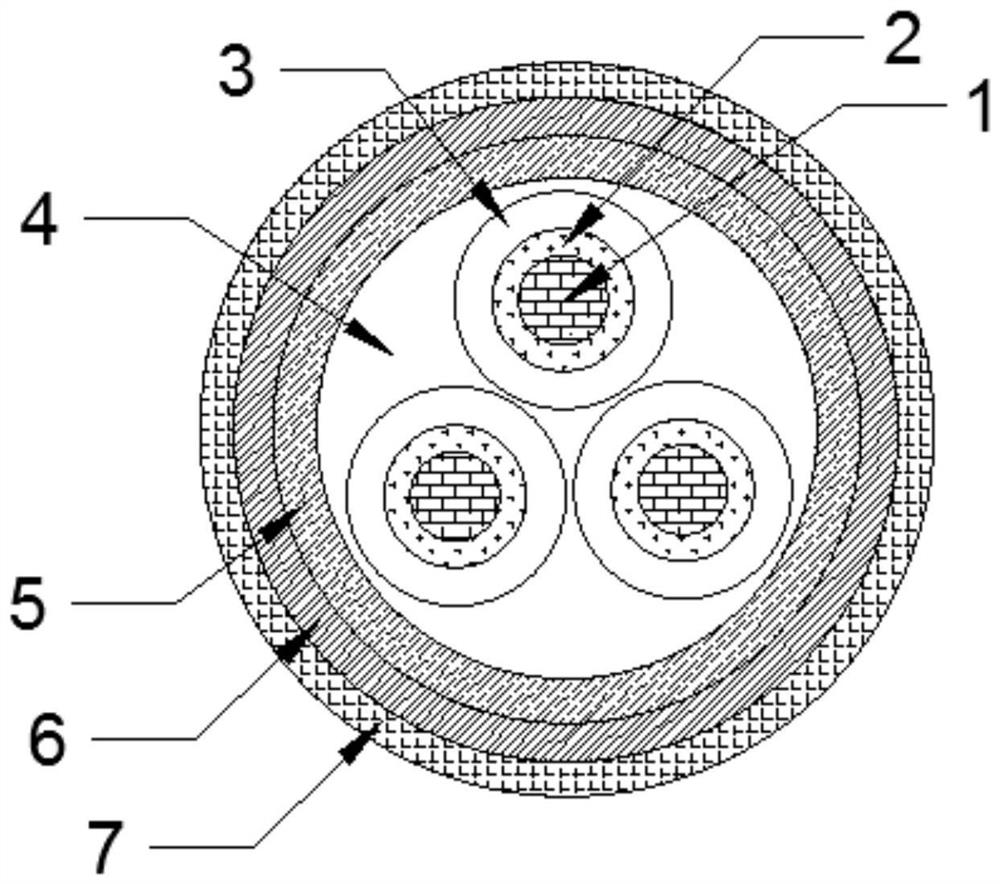

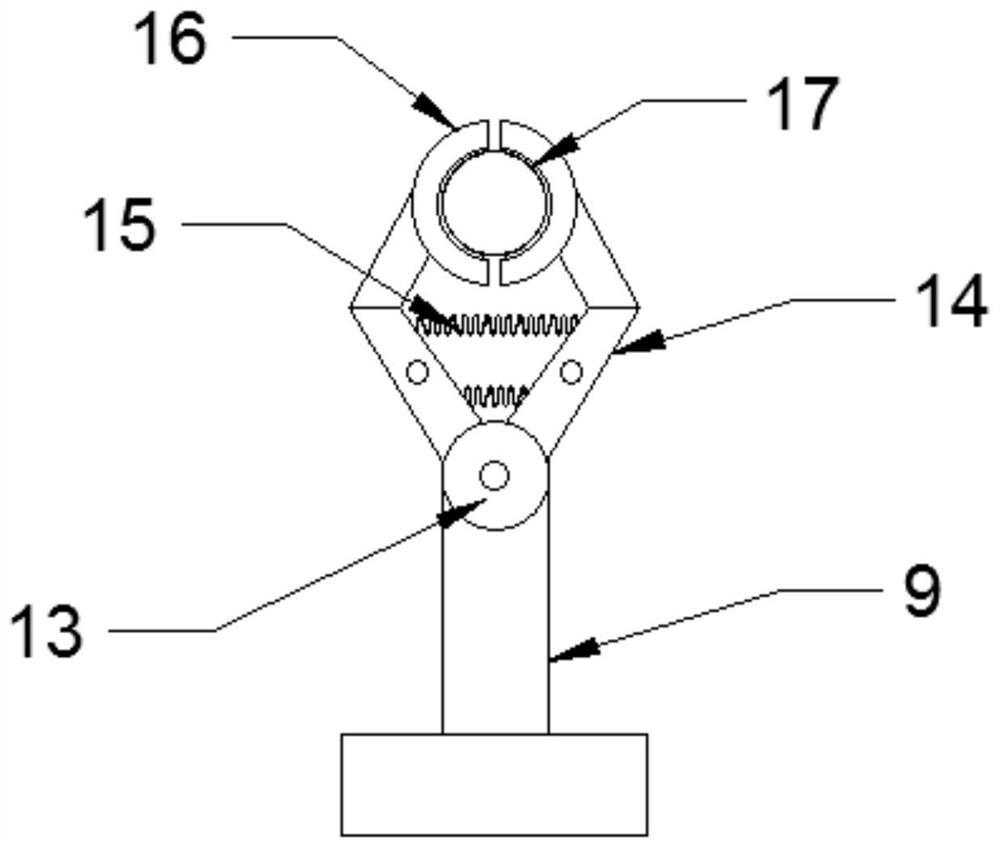

[0033] Such as Figure 1-Figure 3 As shown, a high-temperature-resistant fireproof flexible cable provided in this embodiment includes a cable body 12, a T-shaped fixing seat 9 is installed at an equal angle on the outside of the cable body 12, and a shielding wire clamping assembly is arranged on the T-shaped fixing seat 9. A dry powder storage ring 8 is installed along the ring portion of the cable body 12 between the T-shaped fixed seats 9, and the inside of the dry powder storage ring 8 is provided with a dry powder detection ejection assembly. The cable body 12 includes a quartz fiber braided outer protective layer 7, a ceramic fiber bag With protective layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com