Method for designing PCB coil device of wireless power transmission system

A wireless power transmission and coil device technology, applied in circuit devices, coils, coil manufacturing, etc., can solve the problems of large skin effect and proximity effect, affecting the overall parameters of the system, and easy deformation of coils, achieving skin effect and Low proximity effect, high transmission efficiency, and the effect of saving equipment volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

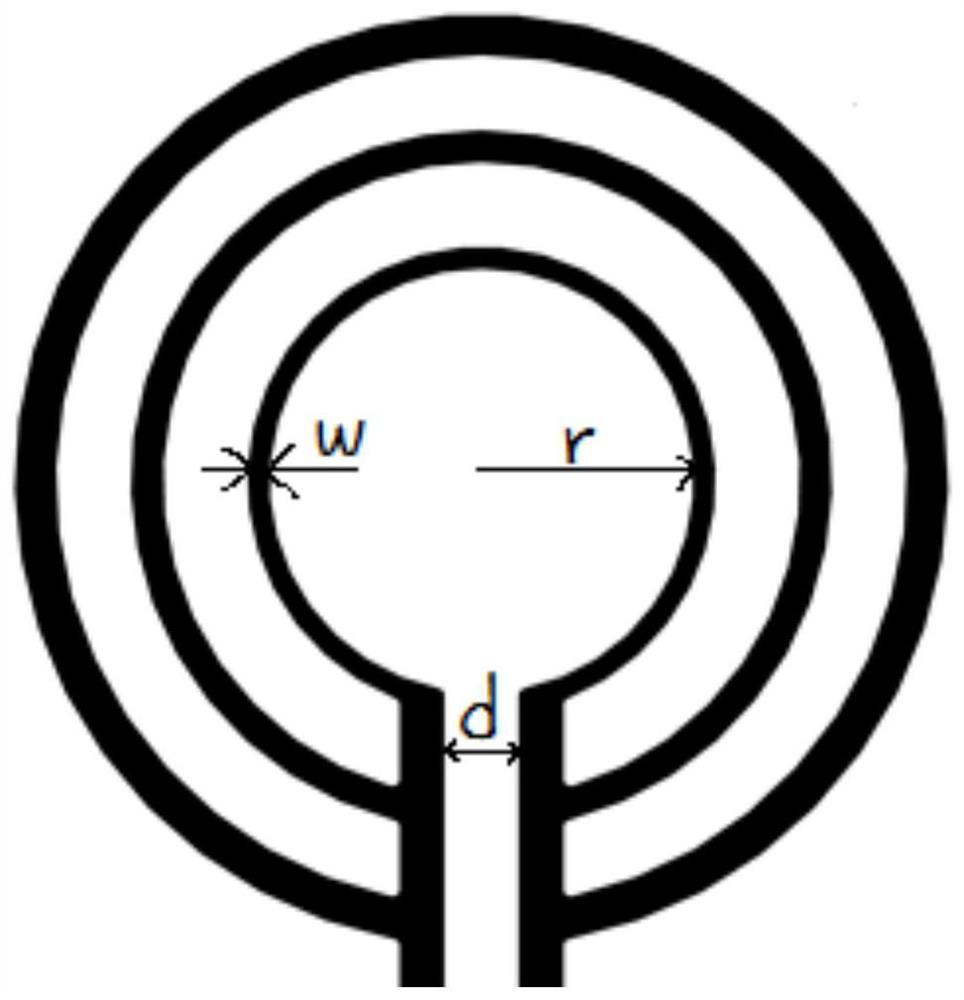

[0044] See attached figure 1 , the excitation-load coil device is composed of three parallel single-turn coils, and the radius of the coils should be larger in order to better excite the transmitting and receiving coils. Therefore, the innermost ring should not be designed too small, that is, the distance between two adjacent parallel coils should be as small as possible. The width w, radius r and resistance R of the coil are calculated by the following a formula:

[0045]

[0046] In the formula: h is the printing thickness. Considering the process reasons, the thickness of the PCB printed circuit should not be changed; ρ is the resistivity of the printing material. Generally, copper is used for PCB printing, and its resistivity is 1.75×10 -8 Ω·m; 2πr-d is the length of each coil; wh is the cross-sectional area of the wire.

[0047] The inductance value of the coil can be regarded as the parallel connection of three individual coils, but the diameter and width of each ...

Embodiment 2

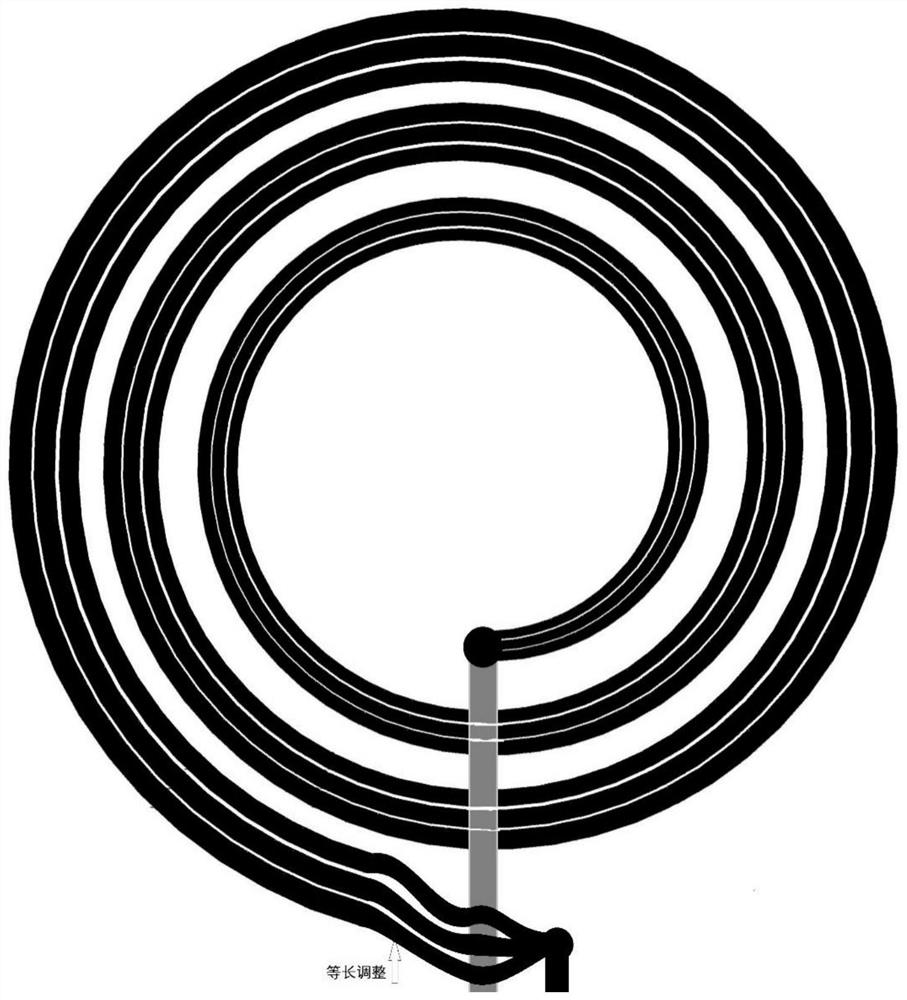

[0058] See attached figure 2 , the transmitting-receiving coil device is a planar helical coil composed of three thinner equal-length wires, and theoretically, the more turns of the thin wires, the better. The design of the coil with a thinner center and thicker edges can improve the performance of the coil. A serpentine bend is designed on the outer edge of the coil, which can change the length of the line without increasing the inductance, so that the resistance of each turn of the coil remains consistent. In actual design, in order to increase the conduction capacity of the coil, in addition to increasing the width of the coil, the coil can also be designed as a four-layer board or a multi-layer board. Multi-layer boards can also be used to increase the number of turns of the coil, so the inductance value of the coil device can be very precise.

[0059] The inductance value of the planar spiral coil can be obtained by finite element simulation like the excitation-load co...

Embodiment 3

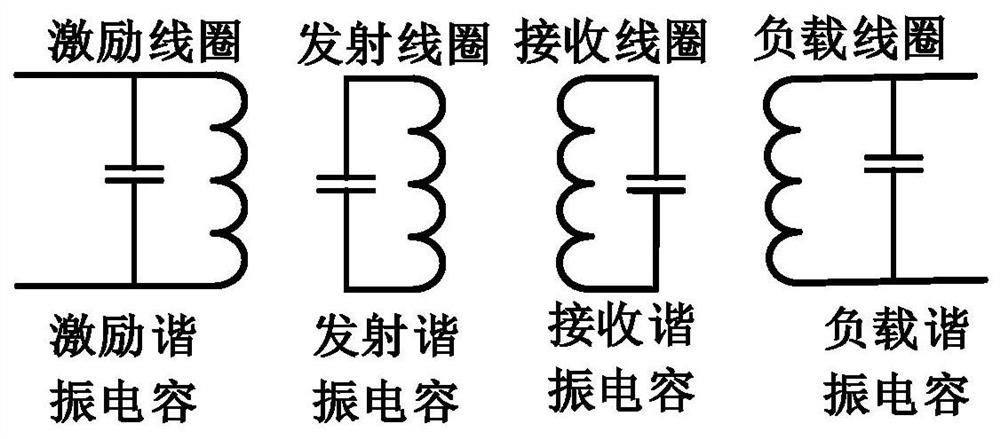

[0062] See attached Figure 3 ~ Figure 5 , taking the four-coil system as an example, according to the different connection methods of coils and capacitors in the circuit, it can be divided into three resonance forms: parallel-parallel, parallel-series and series-parallel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com