Semiconductor wafer cleaning device and method based on heating and drying mechanism

A technology for heating, drying and cleaning devices, which is used in cleaning methods using liquids, heating to dry solid materials, drying solid materials, etc., to improve cleaning efficiency, avoid tilting, and avoid excessive deposition of water droplets.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

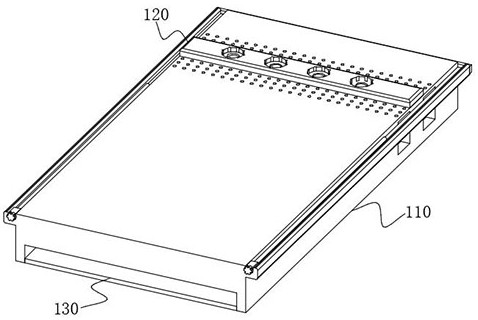

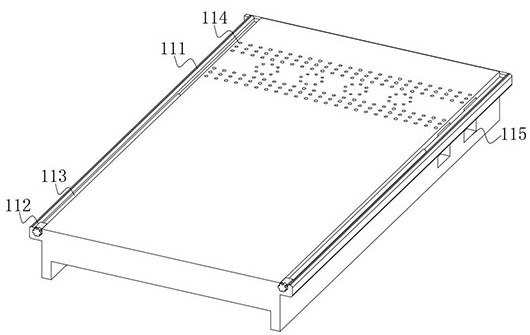

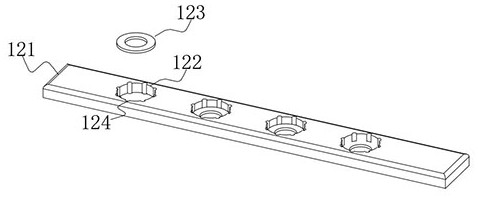

[0066] see Figure 1-12 As shown, one of the purposes of this embodiment is to provide a semiconductor wafer cleaning device based on a heating and drying mechanism, including a bottom mechanism 10, a top mechanism 20 installed on the top of the bottom mechanism 10, and a drying device installed on the side of the top mechanism 20 30. The bottom mechanism 10 includes a bottom plate 110, top grooves 111 are provided on both sides of the top of the bottom plate 110, a placement piece 120 is installed on the top of the bottom plate 110, the placement piece 120 includes a placement plate 121, and several card slots 122 are arranged on the top of the placement plate 121. The bottom end of the groove 122 is provided with a bottom ring 123, and the top mechanism 20 at least includes:

[0067] The support plate 210, the bottom end of the support plate 210 is provided with several hydraulic rods 211, the top of the support plate 210 is provided with a bracket 212, the support 212 is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com