Lithium ion battery system and fixing device thereof

A lithium-ion battery and fixing device technology, applied in the field of lithium-ion batteries, can solve problems such as increased battery loss, high temperature of battery modules, and low safety of lithium-ion battery systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

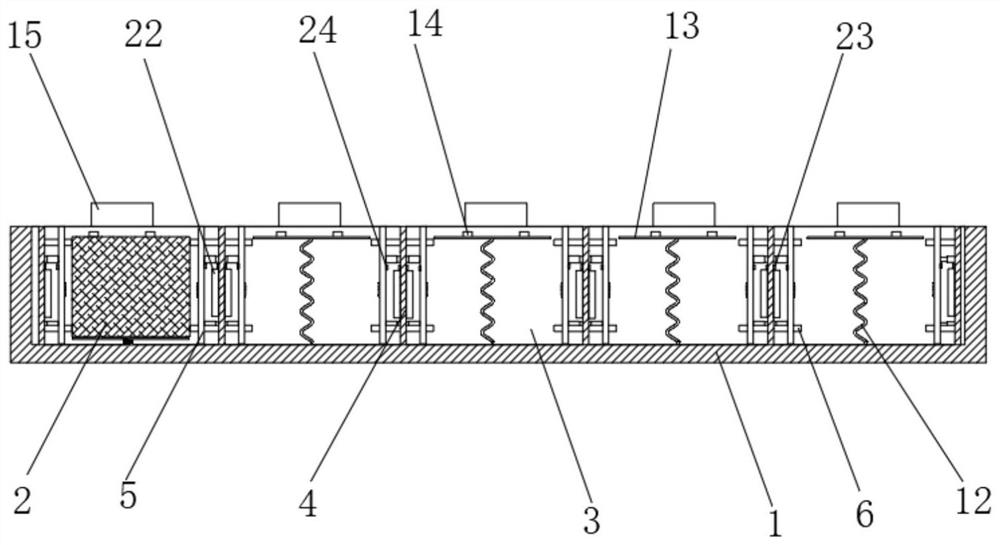

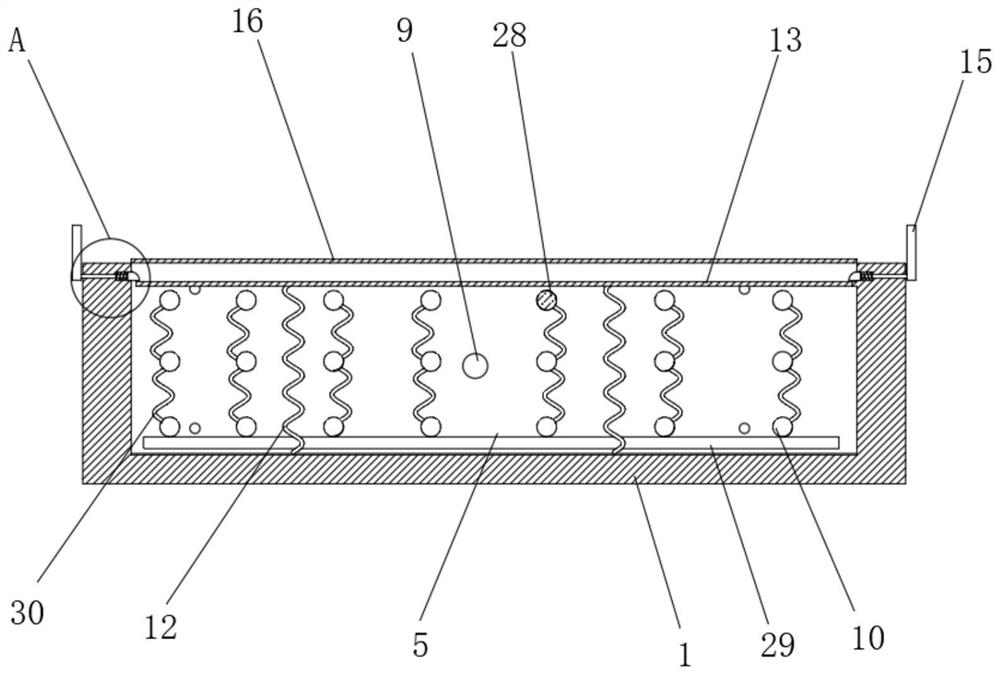

[0034] refer to Figure 1-8, a lithium-ion battery system, comprising a plurality of battery module cells 2 and a battery casing 1 with a plurality of cell installation cavities 3 inside, a heat-assisting assembly is arranged between two adjacent cell installation cavities 3, A plurality of battery module cells 2 and a plurality of heat aiding components are distributed between the heat aiding components at intervals. The heat aiding components include a fixed partition 4 and a pair of heat aiding modules 5, and a pair of heat aiding modules 5 are connected to the fixed spacer. On both sides of the plate 4, the side ends of the fixed partition 4 are clamped with the inner wall of the battery case 1, a pair of heat-assisting modules 5 can slide inside the battery case 1, and a memory expansion body is fixedly connected between the heat-assisted module 5 and the fixed partition 4 8. A plurality of heat dissipation holes 10 are provided on the heating aid module 5, and a dustproo...

Embodiment 2

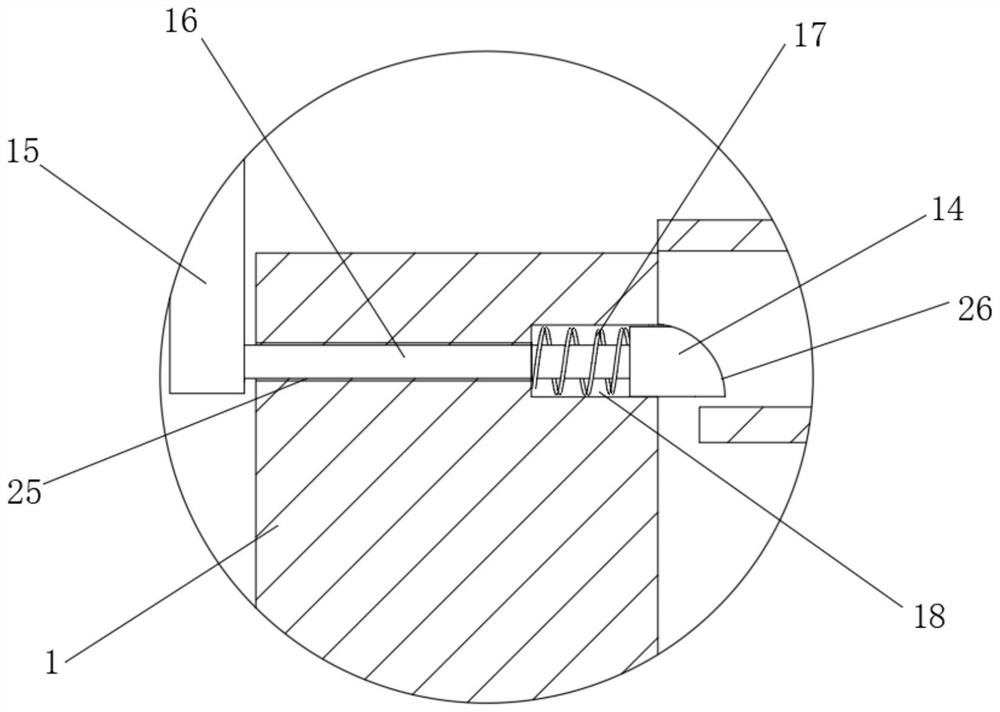

[0042] refer to Figure 1-4 and Figure 7 , a lithium-ion battery system. Compared with Embodiment 1, this embodiment also includes its fixing device for fixing the battery module unit 2. The fixing device includes a push plate 15, a push-pull rod 16, a limit block 14 and Compression spring 2 17, the battery housing 1 inner wall is provided with the receiving groove 18 that slides for limit block 14 and the through hole 25 that slides for push-pull rod 16, and through hole 25 is connected with receiving groove 18, and the two ends of push-pull rod 16 are respectively connected with The limit block 14 is fixedly connected with the push plate 15, the compression spring 17 is sleeved on the outside of the push-pull rod 16, and the two ends of the compression spring 17 are respectively fixedly connected with the inner wall of the storage groove 18 and the limit block 14, and the limit block 14 is away from the push-pull rod. The upper end of the tie rod 16 is set as an arc-shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com