Fermentation process of Pu'er aged materials

A fermentation process, the technology of aged Pu-erh material, applied in the field of fermentation process of aged Pu-erh material, can solve the problems of different fermentation degrees, different air permeability, uneven temperature, etc., achieve the effect of uniform air permeability, strong air permeability, and improved taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A kind of fermentation technology of old Pu'er material, comprises the following steps:

[0038] Wind selection: Air selection is carried out on aged Pu-erh materials to remove dust and broken leaves, so as not to affect the flavor and appearance of later ripened tea.

[0039] Classification: Place the aged Pu’er materials after winnowing in batches on a 10-mesh sieve. Those that pass through the sieve are fine materials, and those that fail are coarse materials. The coarse materials and fine materials are placed in separate piles, and then wetted with water. When wetting, the mass ratio of water to tea leaves is 1:5. First use half of the water to atomize and spray the surface of the tea leaves, then refurbish the tea piles and then spray the remaining water to ensure that the tea leaves are all moist.

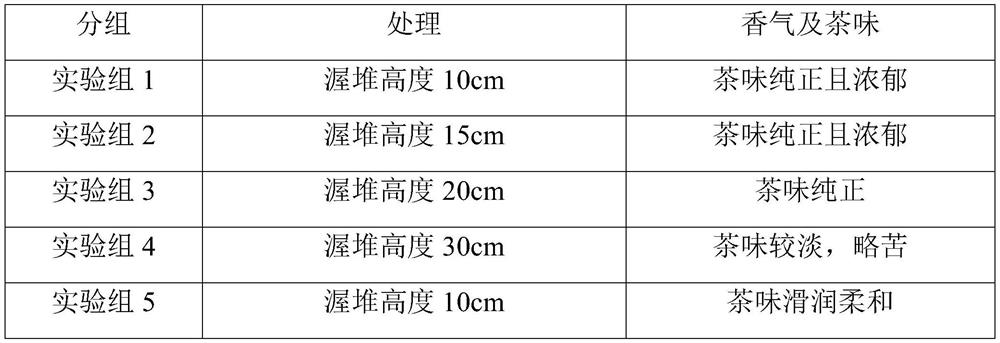

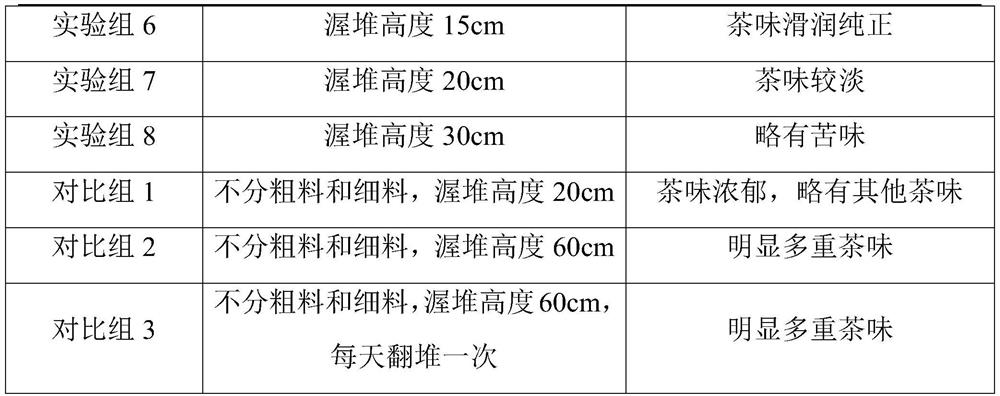

[0040] Fermentation: First, pre-treat and sterilize the fermentation room to kill other miscellaneous bacteria. Multiple fine sieves are placed in the fermentation roo...

Embodiment 2

[0043] A kind of fermentation technology of old Pu'er material, comprises the following steps:

[0044]Wind selection: Air selection is carried out on aged Pu-erh materials to remove dust and broken leaves, so as not to affect the flavor and appearance of later ripened tea.

[0045] Classification: Place the aged Pu’er materials after winnowing in batches on a 10-mesh sieve. Those that pass through the sieve are fine materials, and those that fail are coarse materials. The coarse materials and fine materials are placed in separate piles, and then wetted with water. When wetting, the mass ratio of water to tea leaves is 3:10. First use half of the water to atomize and spray the surface of the tea leaves, then refurbish the tea piles and then spray the remaining water to ensure that the tea leaves are all moist.

[0046] Fermentation: Firstly, the fermentation room is pre-treated and sterilized to kill other miscellaneous bacteria. Multiple fine sieves are placed in the fermenta...

Embodiment 3

[0049] A kind of fermentation technology of old Pu'er material, comprises the following steps:

[0050] Wind selection: Air selection is carried out on aged Pu-erh materials to remove dust and broken leaves, so as not to affect the flavor and appearance of later ripened tea.

[0051] Classification: Place the aged Pu’er materials after winnowing in batches on a 10-mesh sieve. Those that pass through the sieve are fine materials, and those that fail are coarse materials. The coarse materials and fine materials are placed in separate piles, and then wetted with water. When wetting, the mass ratio of water to tea leaves is 1:5. First use half of the water to atomize and spray the surface of the tea leaves, then refurbish the tea piles and then spray the remaining water to ensure that the tea leaves are all moist.

[0052] Fermentation: First, pre-treat and sterilize the fermentation room to kill other miscellaneous bacteria. Multiple fine sieves are placed in the fermentation roo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com