Deburring device for Chinese chestnut processing

A processing device and burr technology, which is applied in the field of deburring devices for chestnut processing, can solve problems such as incomplete removal of burrs, inconvenient cleaning, and adhesion of burrs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

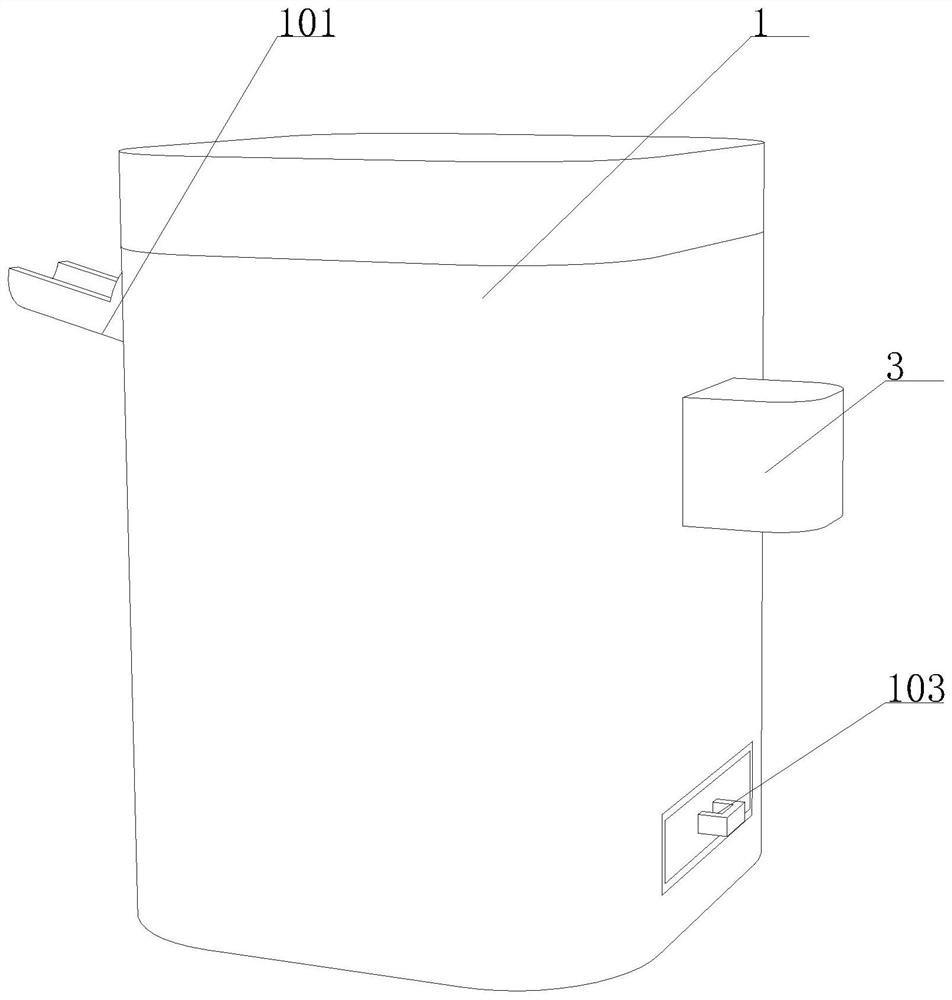

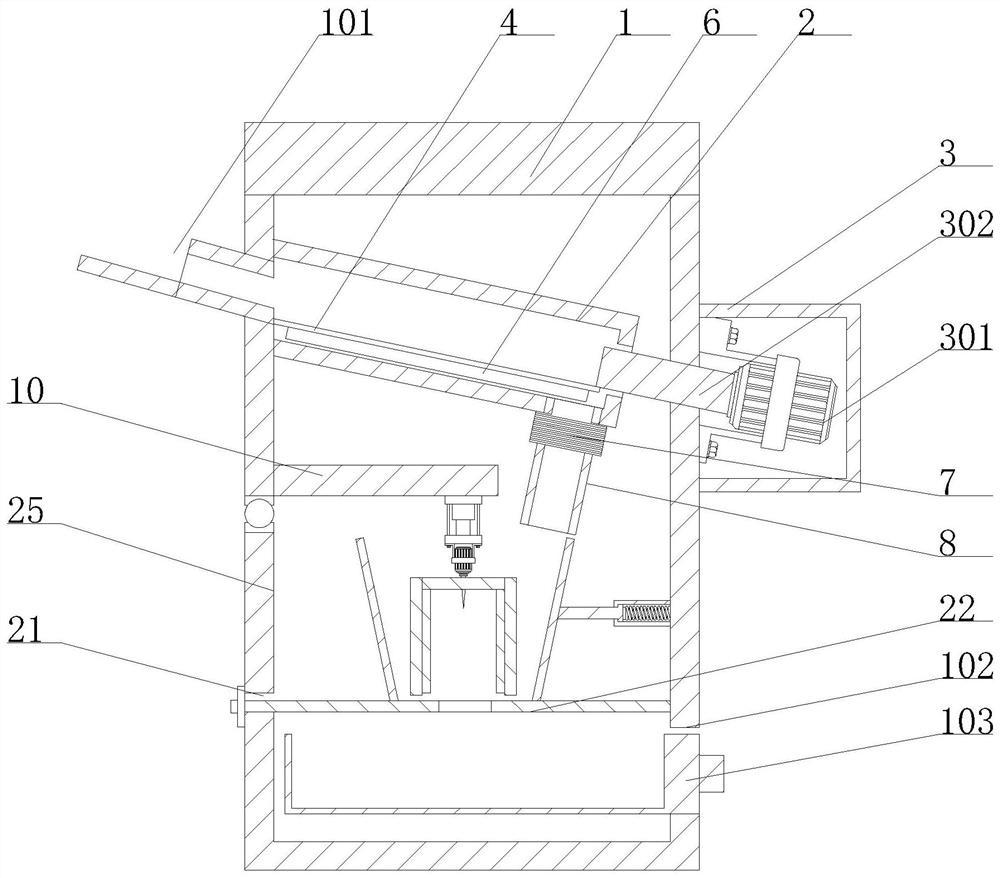

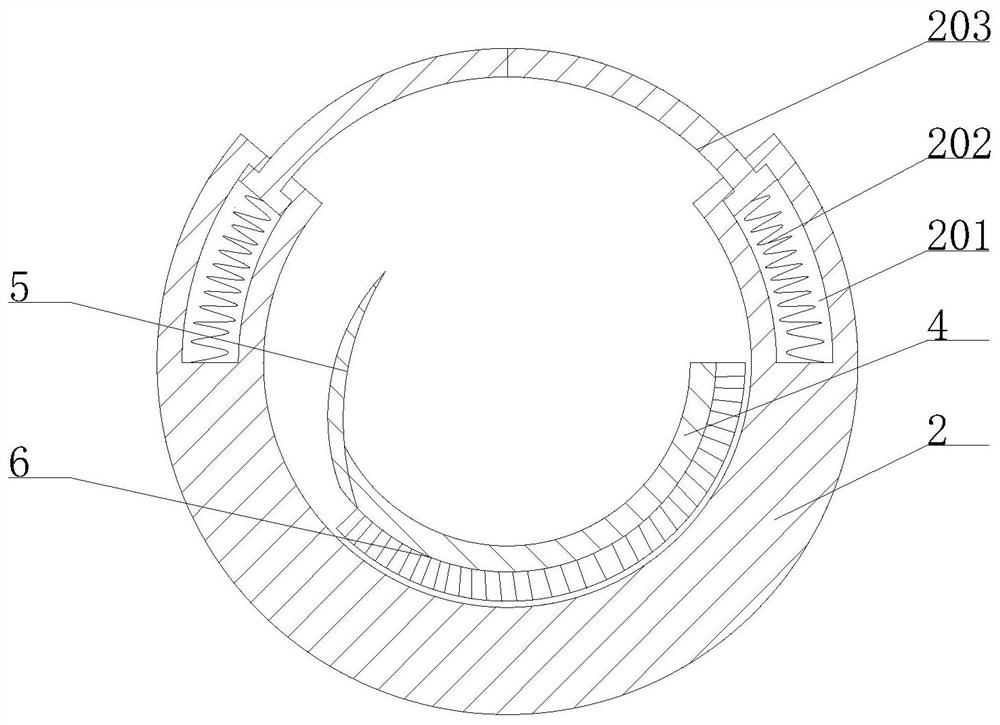

[0034] Such as figure 1 - Figure 7As shown, the present invention provides a kind of deburring device for chestnut processing, comprising processing device shell 1, processing pipeline 2, drive chamber 3, rotating bracket 4, arc scraper 5 and hairbrush 6, the processing device shell 1 The top of the left side is provided with a feed pipe 101, and the top of the inner wall of the processing device shell 1 is provided with a processing pipeline 2. The feed pipe 101 runs through the left side of the processing device shell 1 and communicates with the processing pipeline 2. A driving chamber 3 is provided, the inner wall of the driving chamber 3 is provided with a first driving motor 301, and the first driving motor 301 penetrates the right side of the processing device shell 1 and extends inside the processing pipeline 2 through the transmission rod 302 provided, and the transmission The right end of bar 302 is fixedly connected with rotating support 4, and the top of rotating ...

Embodiment 2

[0036] Such as figure 2 - Figure 5 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: the bottom of the processing pipeline 2 is provided with a diversion pipeline 7, the top of the diversion pipeline 7 is provided with a valve 8, and the left side of the inner wall of the processing device shell 1 A horizontal plate 10 is provided, the bottom of the horizontal plate 10 is provided with a small cylinder 11, the bottom of the small cylinder 11 is provided with a second driving motor 12, the bottom of the second driving motor 12 is provided with a transmission bracket 13, and the bottom of the transmission bracket 13 is provided with The thimble 1301, the bottom left end of the transmission bracket 13 is provided with a first elastic frame 14, the bottom right end of the transmission bracket 13 is provided with a second elastic frame 15, and the inner sides of the first elastic frame 14 and the second elastic frame 15 are provided with...

Embodiment 3

[0038] Such as figure 2 - Figure 7 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: preferably, the right side of the processing device housing 1 is provided with a first sliding groove 102, and the inner wall of the first sliding groove 102 is slidably connected There is a sliding storage box 103, the left side of the processing device shell 1 is provided with a second sliding groove 21, the second sliding groove 21 is located above the first sliding groove 102, and the inner wall of the second sliding groove 21 is slidingly connected with a screening plate 22, The surface of the screening plate 22 is provided with a screen hole 23, the left side of the screening plate 22 is provided with a handle 24, the top of the processing pipeline 2 is provided with an arc-shaped groove 201, and the inner wall of the arc-shaped groove 201 passes through the first spring 202 provided. An arc-shaped baffle 203 is movably conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com