Gravel crusher

A crusher and gravel technology, applied in grain processing, etc., can solve the problems of sieve plate shutdown, hammer head wear fast, material caking, etc., and achieve the effects of reducing resistance, reducing dust pollution, and accelerating fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

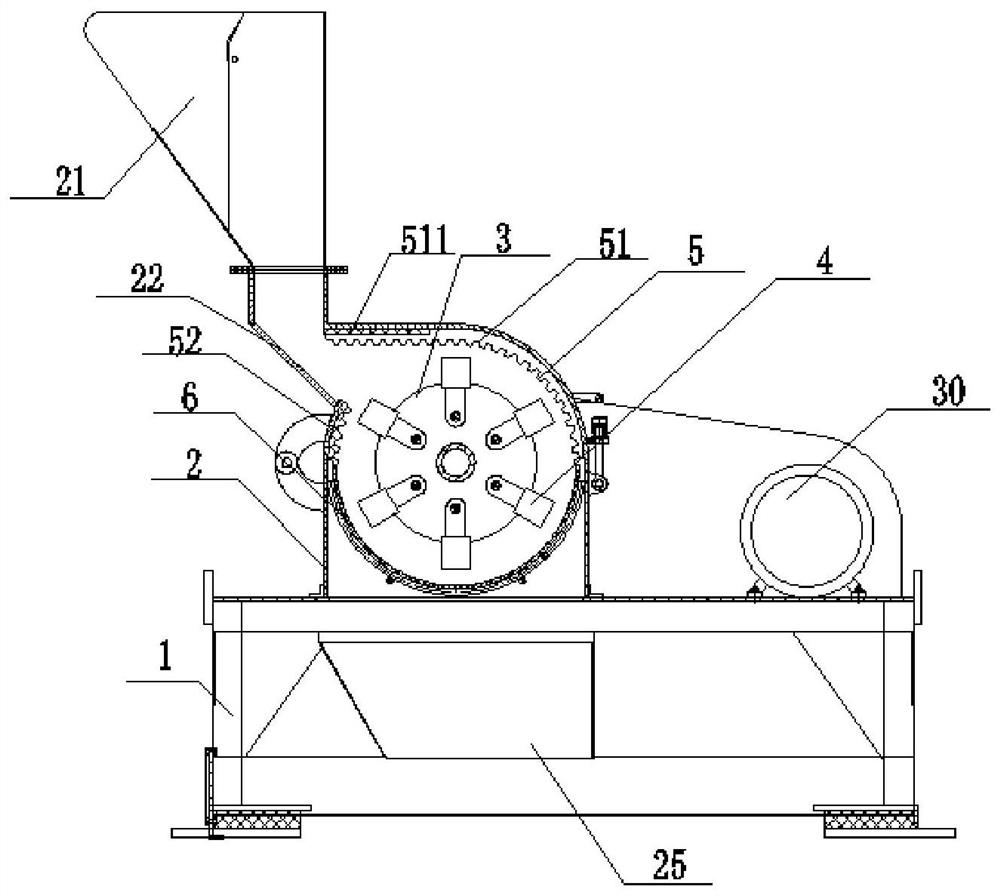

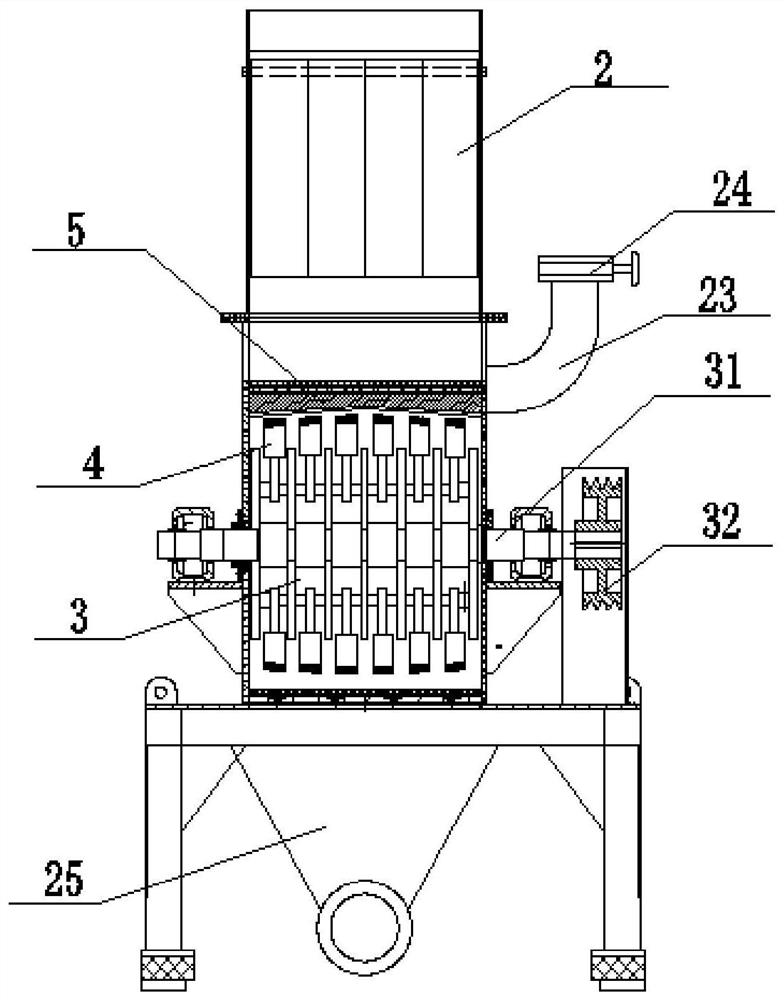

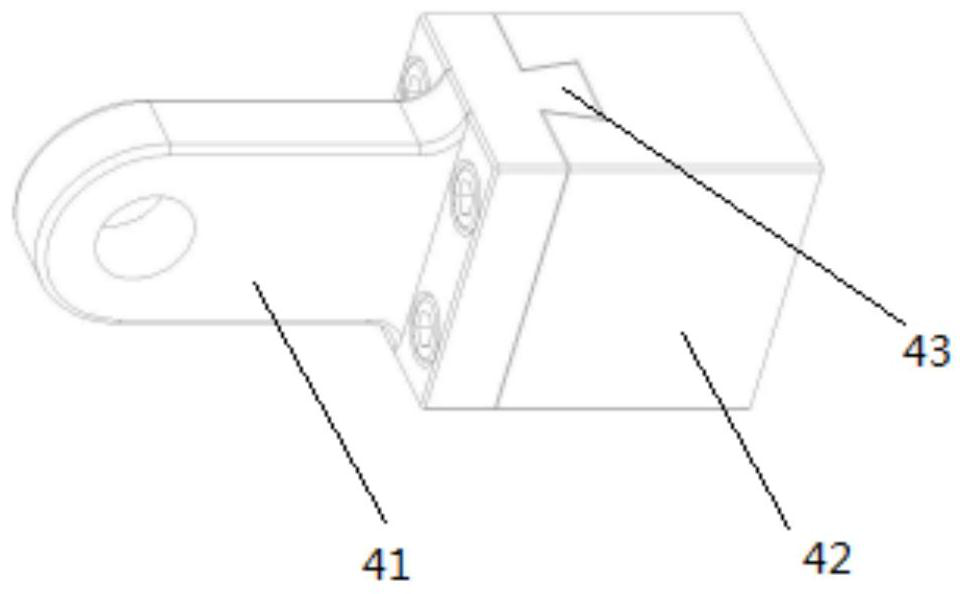

[0018] refer to Figure 1 to Figure 5 A kind of gravel crusher of the present invention comprises frame 1, pulverizer box 2, rotor 3, pulverizer assembly 4, tooth plate 5 and sieve plate 6, and pulverizer box 2 is installed on described frame 1, and pulverizer box 2 is provided with a rotor 3, and the circumference of the rotor 3 is uniformly equipped with a crushing hammer assembly 4, and the inner wall of the upper part of the crushing machine box 2 is equipped with a tooth plate 5, and the tooth plate 5 is matched with the crushing hammer assembly 4. A sieve plate 6 is installed below the pulverizer case 2, a feed hopper 21 is installed above the pulverizer case 2, and a discharge hopper 25 is provided below the pulverizer case 2, and the discharge hopper 25 is located below the sieve plate 6 . The cross-sectional shape of the rack on the tooth plate 5 is approximately an inverted V shape, and the contour of the line connecting the tops of the crushing hammer assemblies 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com