Elastic check ring for opening part of sliding universal joint and manufacturing method of elastic check ring

A technology of retaining rings and universal joints, which is applied in the direction of manufacturing tools, metal processing equipment, feeding devices, etc., and can solve problems such as unfavorable disassembly, parts forming damage, and high process control costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

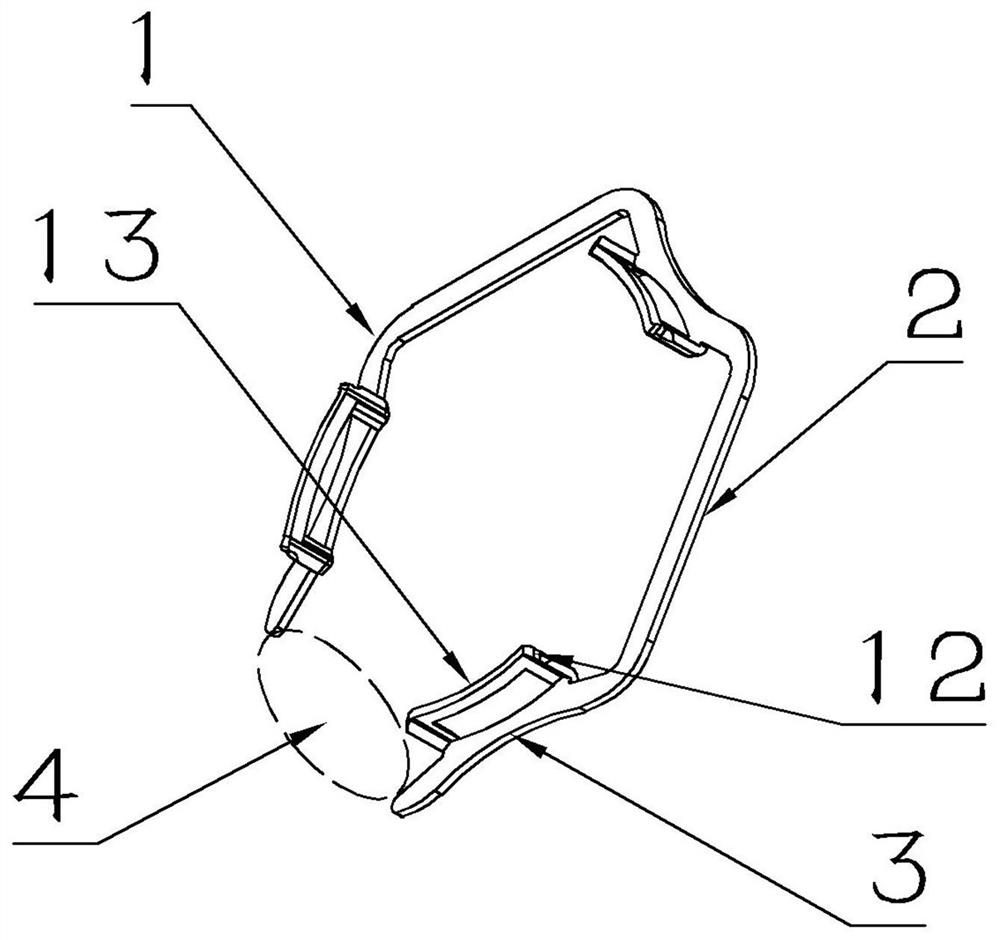

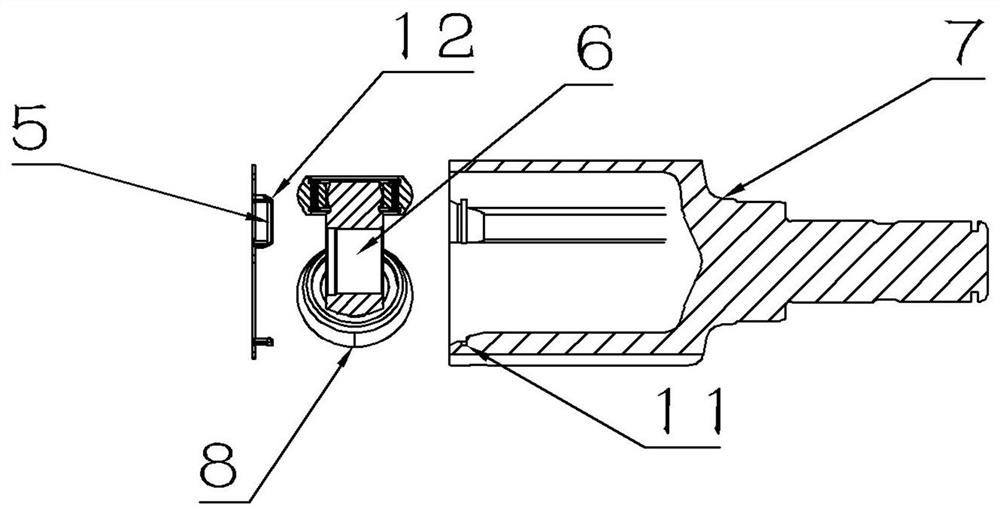

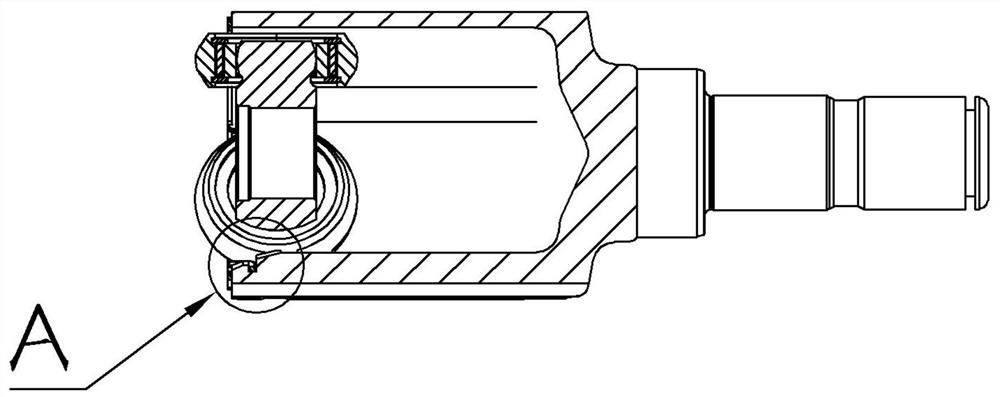

[0034] The elastic retaining ring at the mouth of the sliding universal joint described in this embodiment, such as Figure 1 to Figure 5 As shown, it mainly includes a retaining ring main body 1. The retaining ring main body 1 includes a connecting plate 2, a blocking plate 3, and an opening 4. Both sides of the connecting plate 2 are connected with the blocking plate 3. On the blocking plate 3 An elastic blocking member is provided, and the elastic blocking member includes a limiting portion 12 and a fixing member 13 for blocking the ball ring 8 .

[0035] In order to fix the retaining ring body conveniently, the fixing member 13 is a connecting rod connecting the limiting portion 12 .

[0036] In order to facilitate the barrier ball ring 8, such as Figure 7 As shown, the distance X between the adjacent limiting portions 12 is smaller than the diameter of the ball ring 8 .

[0037] In order to realize the manufacture of the elastic retaining ring at the mouth of the slidi...

Embodiment 2

[0054] The circlip at the opening of the sliding universal joint described in this embodiment is different from the features described in Embodiment 1 in that the manufacturing method of the circlip at the opening of the sliding universal joint designed in the present invention includes the following steps:

[0055] a) if Figure 10 As shown in a1 in , place the material sheet on the stamping equipment, such as Figure 10 As shown in a2, the semi-finished product is stamped out;

[0056] b) Place the semi-finished product on the conformal mold, and then finish the semi-finished product with a finishing punch to form a finished product;

[0057] c) Remove sharp corners and burrs from the finished product;

[0058] d) Heat treatment of the finished product.

[0059] In order to reduce waste, the method of stamping out the semi-finished product adopted in this embodiment is the method of one mold with multiple pieces.

[0060] The step d1) is quenching, which includes heating t...

Embodiment 3

[0063] The circlip at the mouth of the sliding universal joint described in this embodiment differs from the characteristics described in Embodiment 2 in that d1) of the step is quenching, which includes heating the finished product to 830 degrees Celsius and keeping it warm for 75 seconds, and then oil cold; the step d2) is tempering, the tempering temperature is 300 degrees Celsius, and it is kept in a nitrate furnace for 30 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com