Diamond circular saw blade cleaning machine

A technology for circular saw blades and cleaning machines, which is applied to metal sawing equipment, dryers, metal processing equipment, etc. It can solve the problems of poor cleaning effect, grinding, easy loosening or collision, etc., and achieves improved work efficiency and structure Reasonably simple, low production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

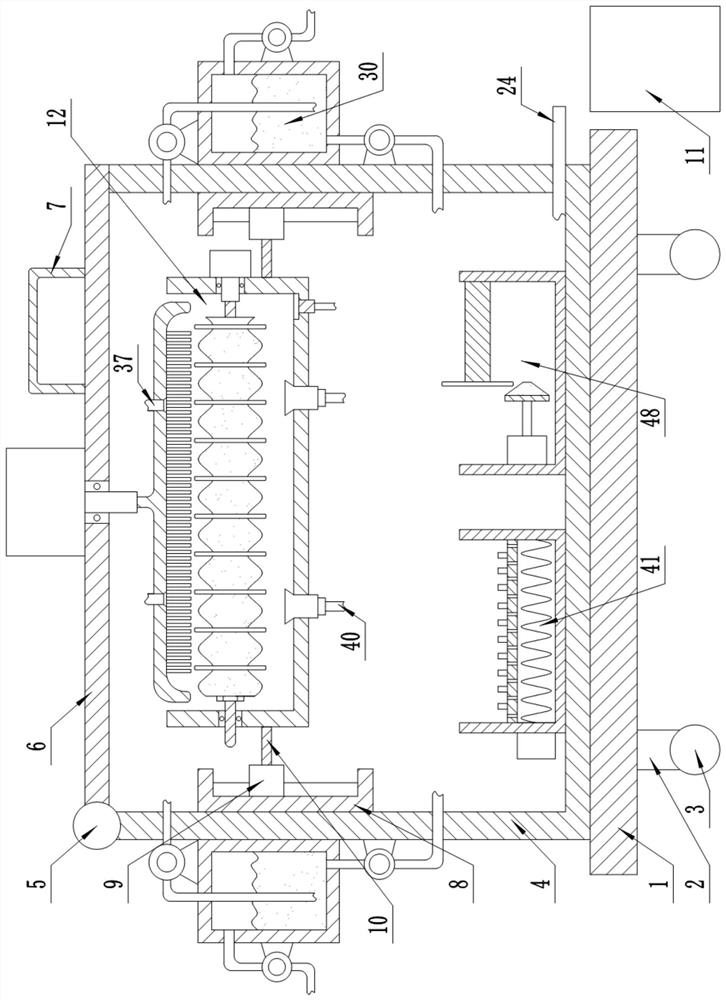

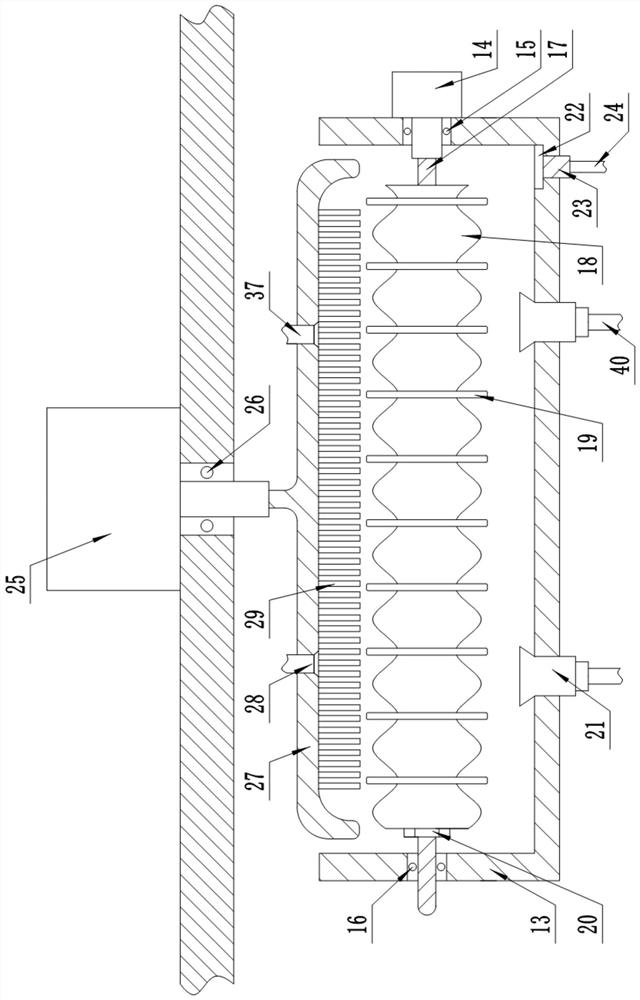

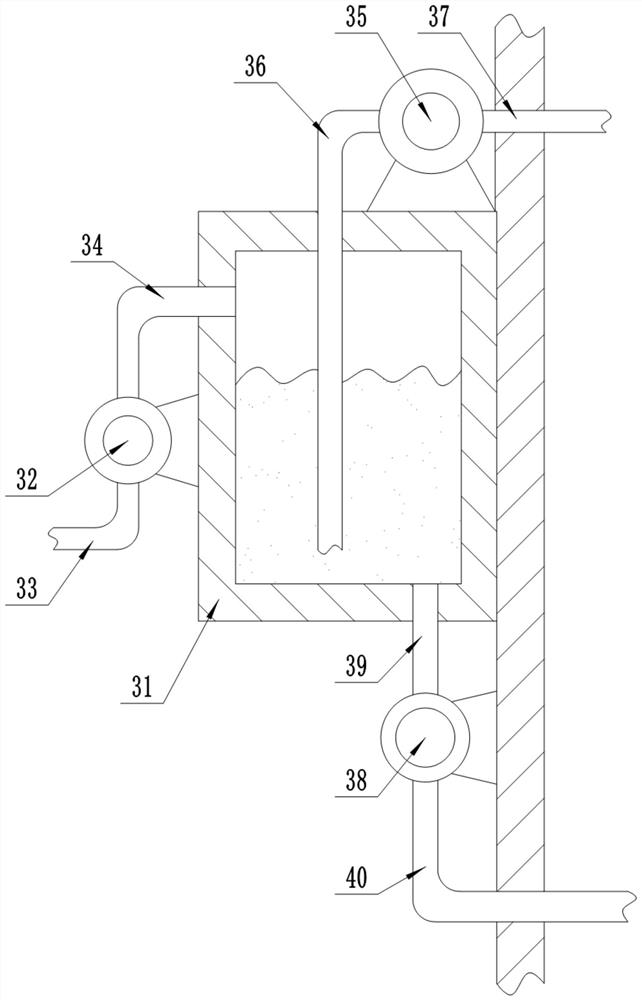

[0024] Such as Figure 1 to Figure 2 As shown, this specific embodiment adopts the following technical solutions: a diamond circular saw blade cleaning machine, including a base 1, a support foot 2, a universal wheel 3, a working box 4, a rotating shaft 5, a cover plate 6, a handle 7, a sliding rail 8, slide block 9, connecting rod 10, collection barrel 11, cleaning device 12, water spray device 30, drying device 41 and polishing device 48; described base 1 lower surface is fixedly connected with supporting foot 2 around; The bottom end of the foot 2 is connected with a universal wheel 3; the work box 4 is fixedly connected to the upper end of the base 1; the top of the left end wall of the work box 4 is hinged with a cover plate 6 through a rotating shaft 5; the upper surface of the cover plate 6 is right The side is fixedly connected with a handle 7; the middle ends of both sides of the chamber of the working box 4 are fixedly connected with slide rails 8; There is a connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com