Motor stator machining device

A technology for processing devices and motor stators, applied in electric processing equipment, accessory devices, metal processing equipment, etc., can solve the problems of low pass rate of finished workpieces, low degree of material processing automation, and inability to realize flexible processing, etc., to improve processing efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

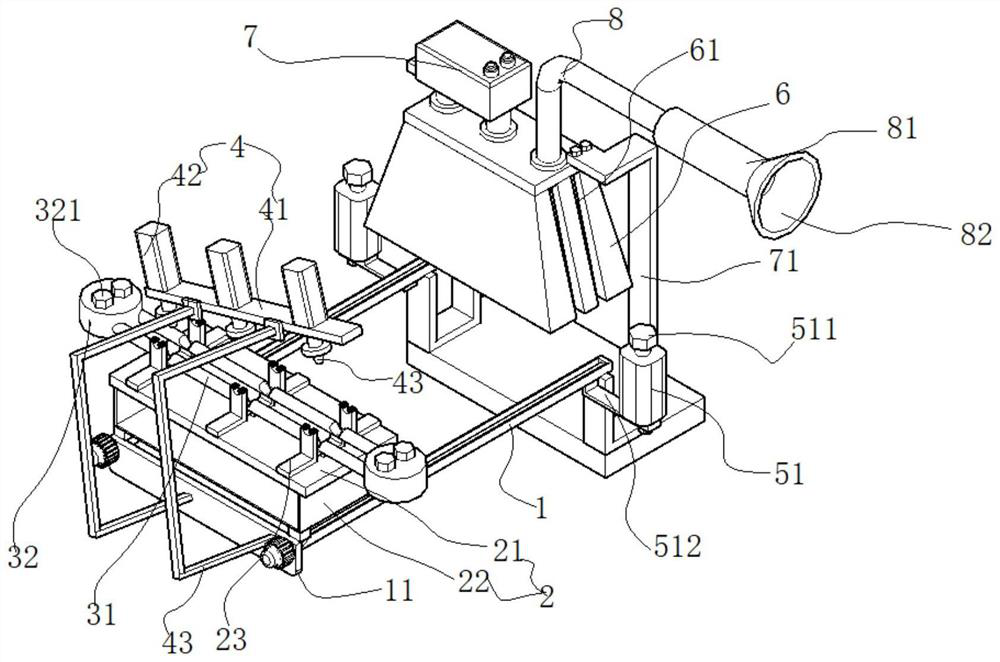

[0068] Such as figure 1 As shown, a motor stator processing device includes sliding frame rods 1 arranged at intervals on the left and right; the sliding frame rod 1 is a rod-shaped frame and a stainless steel frame.

[0069] A feeding assembly 2 is slidably connected between the carriage rods 1 . The material (motor stator workpiece, workpiece including the motor shaft and the winding assembled on the motor shaft), the feeding limit is on the feeding assembly 2, and the automatic lifting and rotating materials are realized through the feeding assembly 2, which is convenient for flexible angle and height switching of materials.

[0070] Specifically, each feeding assembly 2 includes a rectangular material seat plate 21 (the size of the material seat plate 21 is 1.2n in length and 90 cm in width, made of stainless steel plate).

[0071] In order to realize that several material workpieces are carried to limit positions, several material racks arranged at intervals from left to...

Embodiment 2

[0085] Such as Figure 1-6 As shown, in order to realize the forward movement of the feeding assembly 2 and facilitate the entry into the second process for processing, the above feeding assembly 2 also includes a screw driving part 9 that drives the material seat plate 21 to move.

[0086] Specifically, the screw driving part 9 includes four seat blocks 931 fixedly connected to the bottom of the material seat plate 21 , and the seat blocks 931 are respectively located at four corners of the material seat plate 21 . The top of the seat block 931 is mounted on the top surface of the sliding frame rod 1 , specifically, the sliding frame rod 1 is provided with a chute 12 , and the seat block 931 is slidably mounted on the notch of the chute 12 .

[0087] A sliding sphere 93 is fixedly connected to the bottom of each block 931 , and the screw driving part 9 further includes a screw 92 threaded on the sliding sphere 93 .

[0088] Such as figure 1 As shown, the rear end of the lea...

Embodiment 3

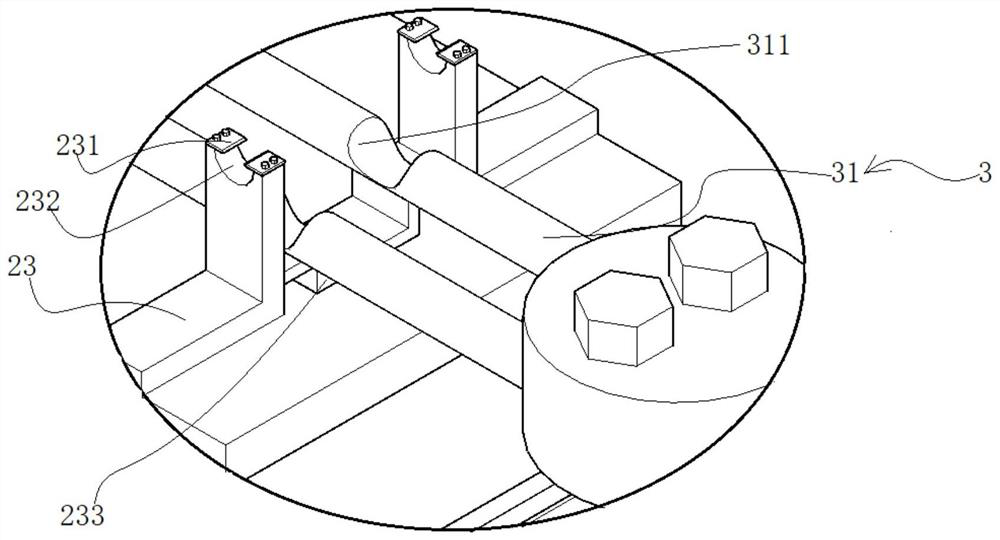

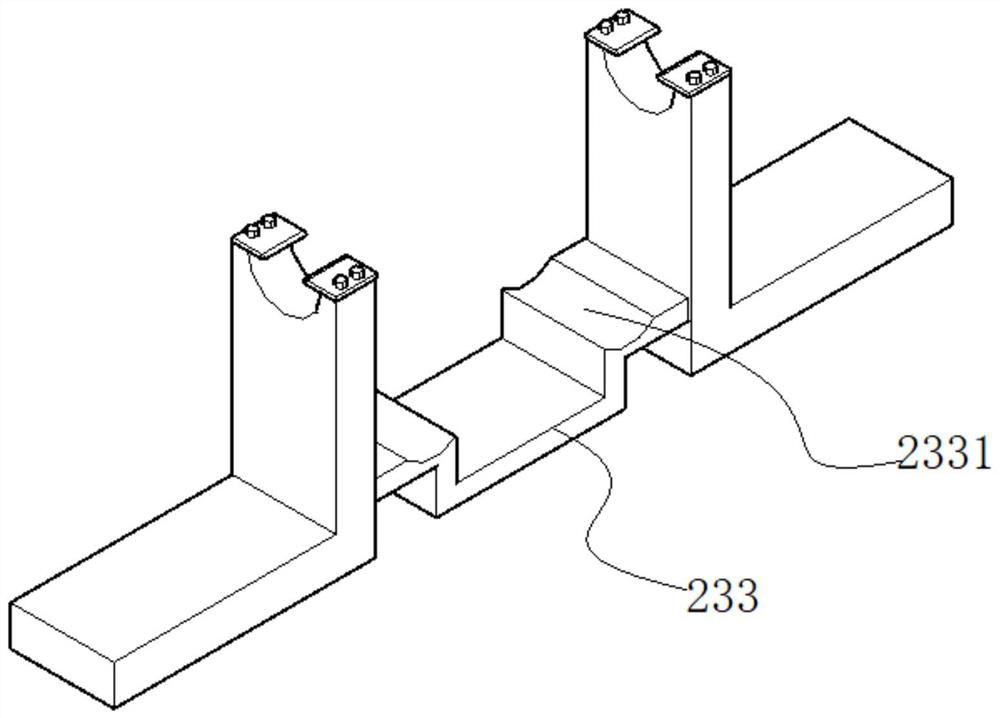

[0094] Such as Figure 1-9 As shown, after the material is processed on the material seat plate 21, it needs to be processed in the next stage of processing. In order to realize the simultaneous removal of the material from the material seat plate 21, there is a ejector rod assembly between the above-mentioned folded connecting plates 233. 3. The ejector rod assembly 3 realizes the simultaneous removal of materials.

[0095] Specifically, the ejector rod assembly 3 includes two ejector rods 32 arranged at intervals between the front and the rear, and the tops of the ejector rods 32 are provided with a plurality of lap notches 311 arranged at intervals from left to right. 311 is located between the racks; end seats 32 are installed between the left and right ends of the ejector rod 32 .

[0096] Specifically, a socket that cooperates with the ejector rod 32 is provided on the end seat 32, and the end of the ejector rod 32 is inserted in the socket. The positioning bolt 321 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com