Flash welding forming method for titanium alloy special-shaped-section annular piece

A special-shaped cross-section, titanium alloy technology, applied in the direction of welding equipment, resistance welding equipment, metal processing equipment, etc., can solve the problems of affecting welding quality, fast surface heat dissipation, virtual welding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0018] The main chemical element content (percentage by weight) of the alloy is: 6.10% Al, 3.92% Zr, 1.97% Mo, 1.95% Sn, 0.07% Si, 0.04% Fe, The C content is 0.01%, the N content is 0.01%, the H content is 0.004%, the O content is 0.11%, and the balance is Ti.

[0019] The flash welding forming process steps of the alloy special-shaped cross-section ring are as follows:

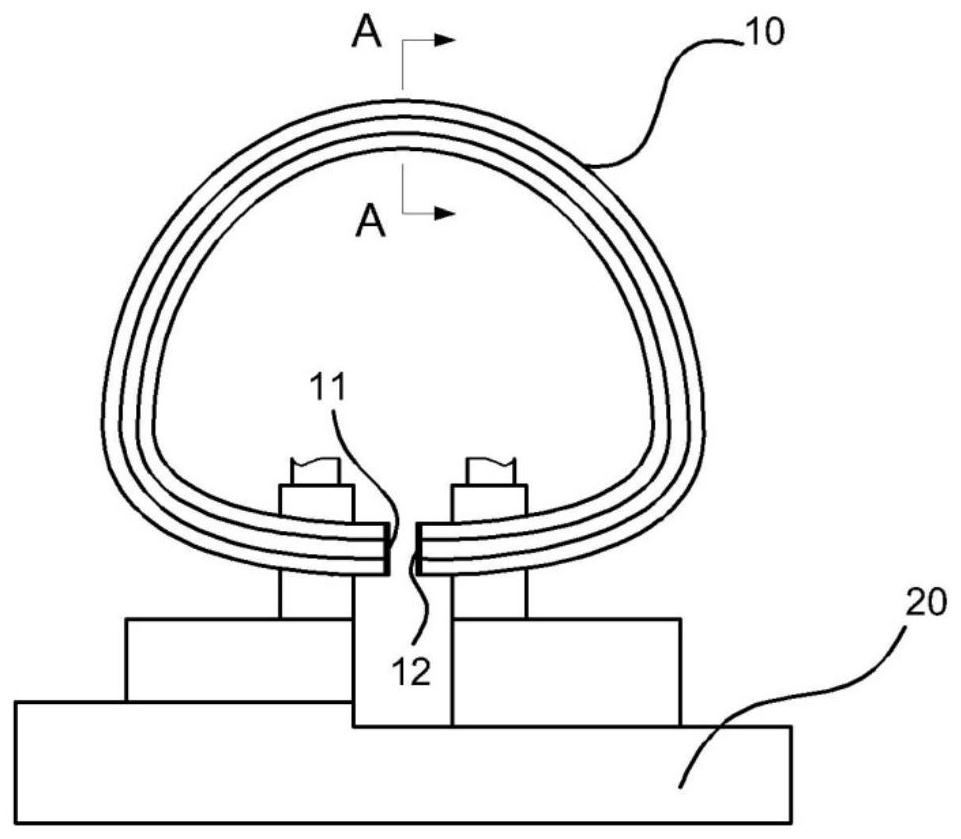

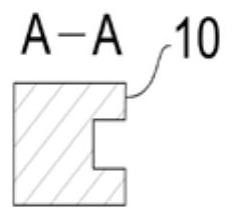

[0020] Step 1: Glitter. like figure 1 As shown, the TI6242 titanium alloy special-shaped cross-section ring blank 10 with openings is clamped on the flash butt welding machine 20; the longitudinal section shape of the ring blank 10 is as follows figure 2 Shown is a lying "concave" shape, that is, a non-rectangular cross-sectional shape. Adjust the distance between the left end face 11 and the right end face 12 at the opening of the ring blank 10 to ≤8mm, start the flash butt welding machine 20 and energize the ring blank 10 with a current of 160KA, so that the opening of the ring blank 10 left end face 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com