Cleaning device for printing model of 3D printer

A 3D printer and model printing technology, applied in the field of 3D printing, can solve the problems of difficult removal of resin particles, irregular shape of model samples, and difficulty in fixing and clamping of model samples, so as to achieve firm fixation and reduce the possibility of extrusion damage. , the effect of thorough cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

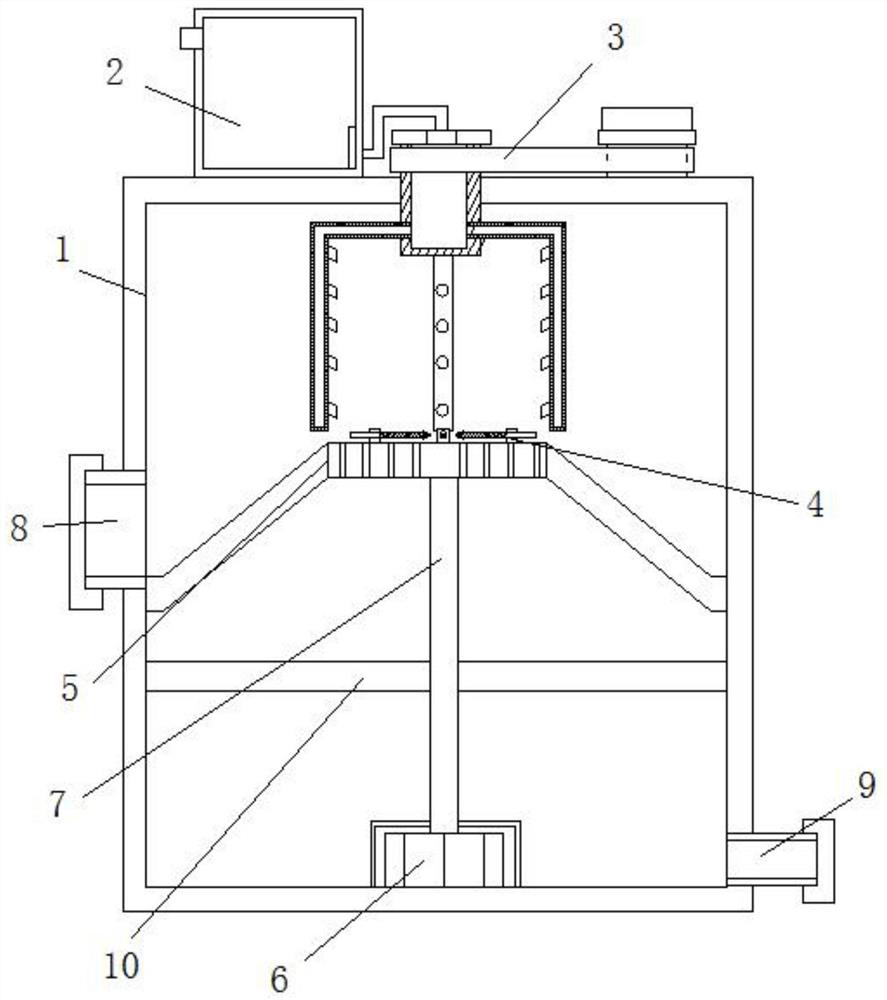

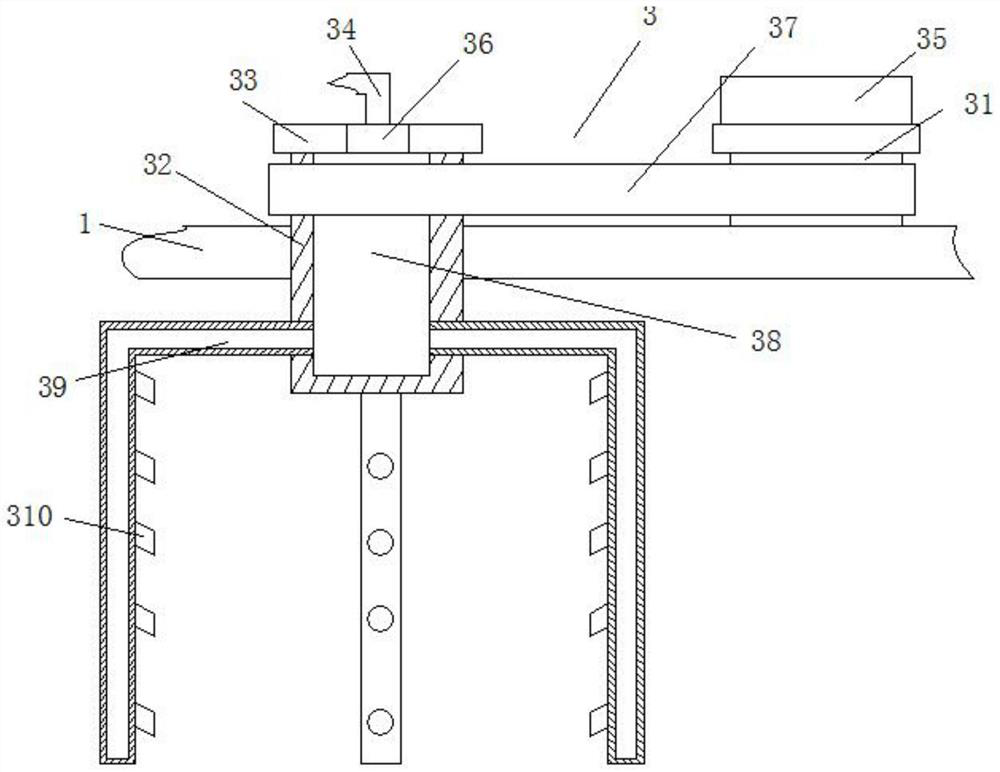

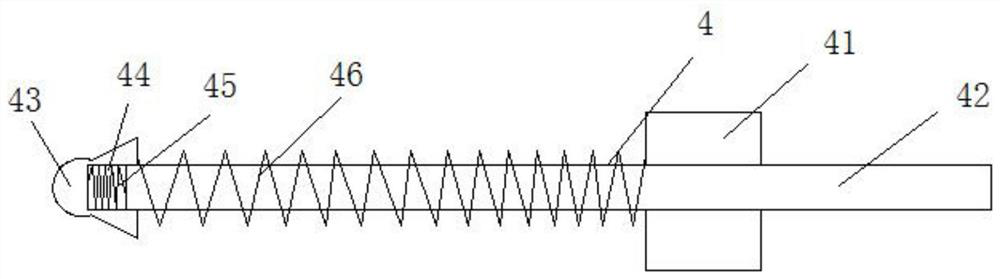

[0024] A 3D printer printing model cleaning device, including a cleaning box 1, an alcohol box 2, a cleaning mechanism 3, a limiting mechanism 4 and a filtering mechanism 5, and the cleaning mechanism 3, the limiting mechanism 4 and the filtering mechanism 5 are all located in the cleaning box 1 cavity, the alcohol tank 2 is connected with the cleaning mechanism 3, and the cleaning mechanism 3 includes a main rotating rod 31 and an auxiliary rotating rod 32, and a transmission belt 37 is connected between the main rotating rod 31 and the auxiliary rotating rod 32, and the main rotating rod 31 and the auxiliary rotating rod 32 are all rotatably connected with the top of the cleaning box 1, the top of the main rotating rod 31 is provided with a first motor 35, the inner cavity center of the auxiliary rotating rod 32 is provided with a cleaning passage 38, and the top of the auxiliary rotating rod 32 is provided with a fixed seat 33 , the top center of the fixed seat 33 is provide...

Embodiment 2

[0026] The difference between the second embodiment and the first embodiment is that the filter mechanism 5 includes a carrying round table 51 and a cover-shaped filter screen 52, the cover-shaped filter screen 52 is fixedly connected to the outer circumference of the carrying round table 51, and the bottom of the carrying round table 51 is provided with an annular Platform 53, and the ring-shaped platform 53 is rotatably connected with the side wall of the inner cavity of the cleaning box 1, and the inner cavity of the bearing round platform 51 is provided with a diversion hole 54, which facilitates the separation of alcohol and resin particles, and also facilitates the automatic removal of resin particles. The inner cavity of the device, between the left and right side walls of the cleaning box 1 cavity below the filter mechanism 5, the limit rod 10 is fixedly connected, and the center of the limit rod 10 is rotatably connected with the rotating shaft 7, so that the rotating s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com