Anti-radiation and anti-crack concrete

A concrete and anti-radiation technology, applied in the field of concrete, can solve problems such as difficulty in preventing radiation, difficult construction, and easy cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

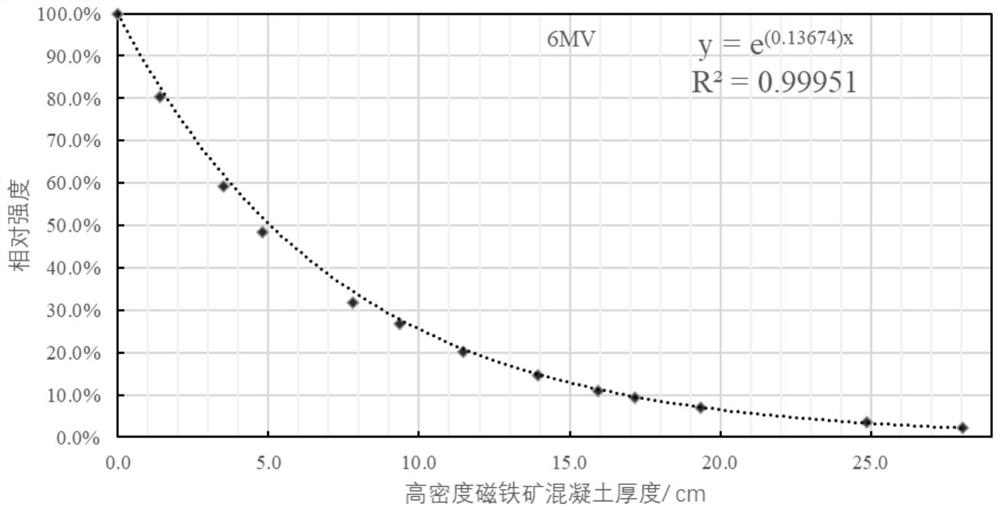

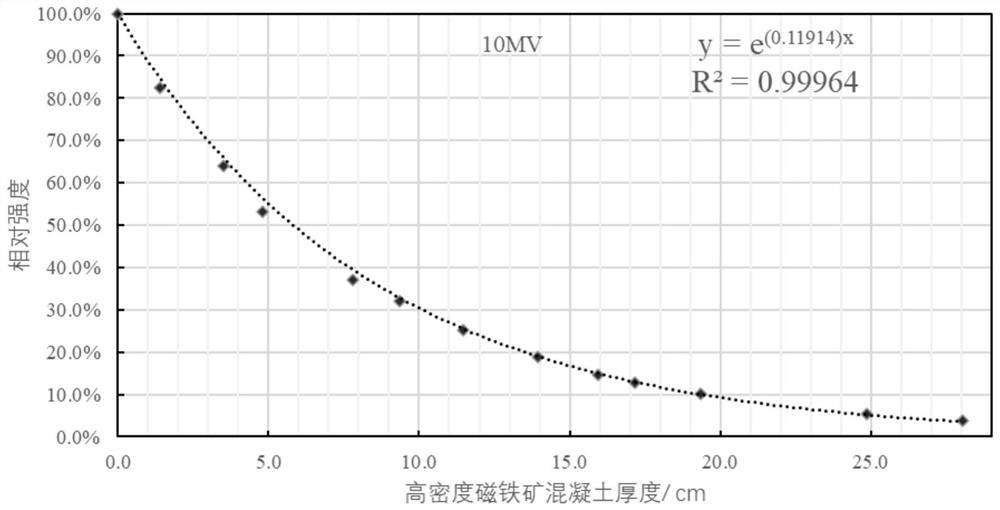

Image

Examples

Embodiment 1

[0036] This embodiment provides a radiation-proof and crack-resistant concrete, which includes the following raw materials: 150kg of cement, 45kg of mineral admixture, 1300kg of magnetite placer, 1700kg of magnetite ore, 20kg of anti-cracking agent, 5kg of water reducing agent and 120kg of water , wherein, the above-mentioned cement is Portland cement, the above-mentioned mineral admixture is a mixture of fly ash above the national standard II level and concrete slag above the S95 level in a ratio of 1:1, and the above-mentioned magnetite placer and the above-mentioned magnetite ore The effective content of iron element is 70%, and the apparent density in the dry state is 4700kg / m 3 , the fineness modulus of the above-mentioned magnetite placer is 3, the particle size of the above-mentioned magnetite ore is 20mm, and the content of needle flake ore is 10%.

[0037] The above-mentioned anti-cracking agent includes 2% of corn starch dextrin cement hydration control material, 30%...

Embodiment 2

[0039] This embodiment provides a kind of anti-radiation and anti-crack concrete, which includes the following raw material components: 450kg of cement, 200kg of mineral admixture, 1600kg of magnetite placer, 2100kg of magnetite ore, 50kg of anti-cracking agent, 15kg of water reducing agent and 220kg of water , wherein, the above-mentioned cement is 42.5 grade ordinary Portland cement, the above-mentioned mineral admixture is made by mixing the fly ash above the national standard II grade and the concrete slag above the S95 grade in a ratio of 1:2, and the above-mentioned magnetite placer and The effective iron content of the above-mentioned magnetite ore is 75%, and the apparent density in the dry state is 4800kg / m 3 , the fineness modulus of the above-mentioned magnetite placer is 2.3, the particle size of the above-mentioned magnetite ore is 5mm, and the content of needle flake ore is 8%.

[0040] The above-mentioned anti-cracking agent includes 4% of corn starch dextrin ce...

Embodiment 3

[0042] This embodiment provides a kind of anti-radiation and anti-crack concrete, which includes the following raw materials: 200 kg of cement, 50 kg of mineral admixture, 1400 kg of magnetite placer, 1800 kg of magnetite ore, 25 kg of anti-cracking agent, 6 kg of water reducing agent and 150 kg of water , wherein, the above-mentioned cement is 52.5 grade ordinary Portland cement, the above-mentioned mineral admixture is a mixture of fly ash above national standard II and above concrete slag in a ratio of 2:1, and the above-mentioned magnetite placer and The effective iron content of the above-mentioned magnetite ore is 80%, and the apparent density in the dry state is 4900kg / m 3 , the fineness modulus of the above-mentioned magnetite placer is 2.3, the particle size of the above-mentioned magnetite ore is 15mm, and the content of needle flake ore is 5%.

[0043] The anti-cracking agent includes 4% of corn starch dextrin cement hydration control material, 30% of light-burned c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Molar mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com